Anti-corrosion and anti-theft grounding electrode

A grounding electrode and anti-theft technology, applied in the direction of connecting contact materials, etc., can solve the problems of being easily stolen, and achieve the effect of convenient and fast installation, good stability and strong conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

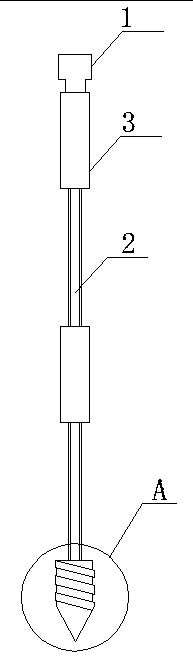

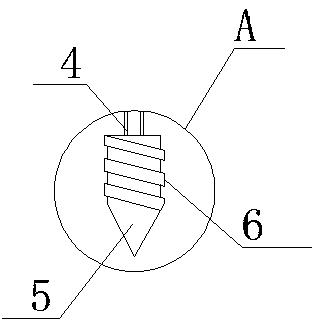

[0029] Such as figure 1 , figure 2 As shown, an anti-corrosion and anti-theft type grounding electrode includes a driving head 1, a grounding rod 2, and connecting rods 3 respectively connected to the two. One end of the driving head and both ends of the grounding rod are provided with external threads, and the two ends of the connecting rod The internal thread is set, the ground rod is a steel core covered with a copper layer 4 on the surface, and the thickness of the copper layer is 0.3mm. The copper layer can be chemically formulated, clad or electroplated depending on the specific situation. From the perspective of use effect, the scheme The electroplating type is preferably used, which evenly covers the low-carbon steel core with 99.9% pure copper, so that the copper and the steel core are completely molecularly combined. The rod end of the ground rod is connected to the drill bit 5, and the outer diameter of the large end of the drill bit is larger than that of the grou...

Embodiment 2

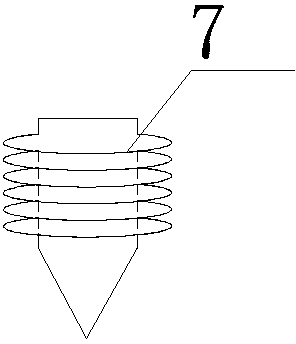

[0036] An anti-corrosion and anti-theft type grounding electrode, the difference from Embodiment 1 is: as image 3 As shown, in this embodiment, the surface of the drill bit is designed as an inverted umbrella tower shape 7 . The inverted umbrella tower shape is a plurality of umbrella-shaped concentric circles, which are vertically combined at a certain distance from each other to form a tower-like structure. After the ground electrode is buried in the ground, the umbrella-shaped protrusion on the surface of the drill bit will hinder the upward force, which is more anti-theft than the traditional conical drill bit.

Embodiment 3

[0038] An anti-corrosion and anti-theft ground electrode, the difference from Embodiment 1 or Embodiment 2 is that in this embodiment, the connection between the ground rod and the drill bit does not use exothermic welding, but uses a connecting rod or a metal buckle; If a connecting rod is used, the upper end of the drill bit should be processed into an external thread suitable for the connecting rod; if a metal buckle is used, one end of the buckle is provided with an internal thread, which can be screwed with the grounding rod, and the other end of the buckle is set card slot. The upper end of the drill bit is processed with locking teeth, and the locking teeth can preferably be cross-shaped or I-shaped, which are compatible with the locking grooves of the buckle, so as to realize the fast clamping connection of the ground rod and the drill bit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com