Manufacturing workshop carbon discharge comprehensive evaluation method

A manufacturing workshop and comprehensive evaluation technology, applied in manufacturing computing systems, instruments, technology management, etc., can solve problems such as unusable, one-sided research goals, ignoring energy utilization, production efficiency, and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0024] The present invention relates to a new multi-attribute compromise method for comprehensive assessment of carbon emissions in a manufacturing workshop, which mainly includes three steps:

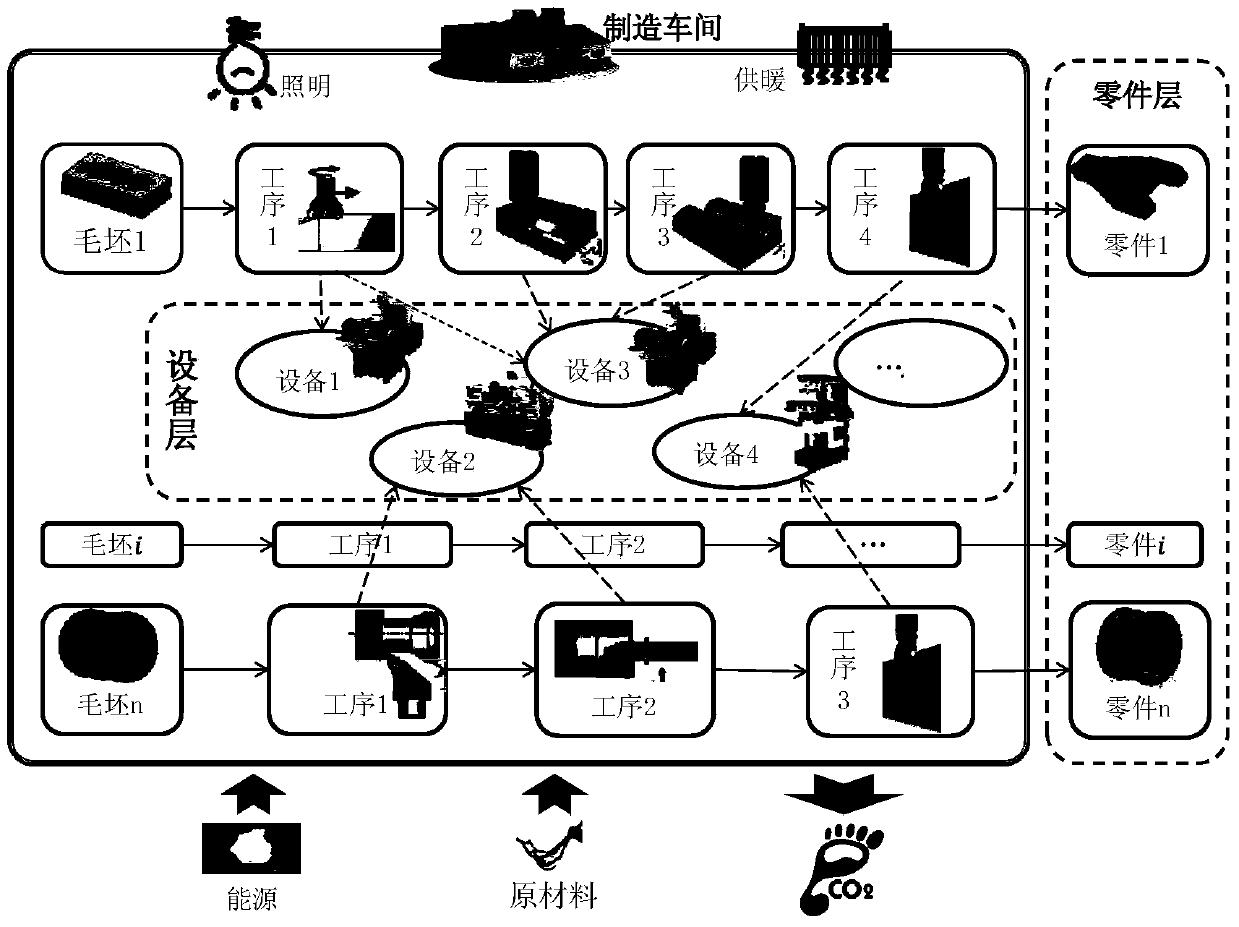

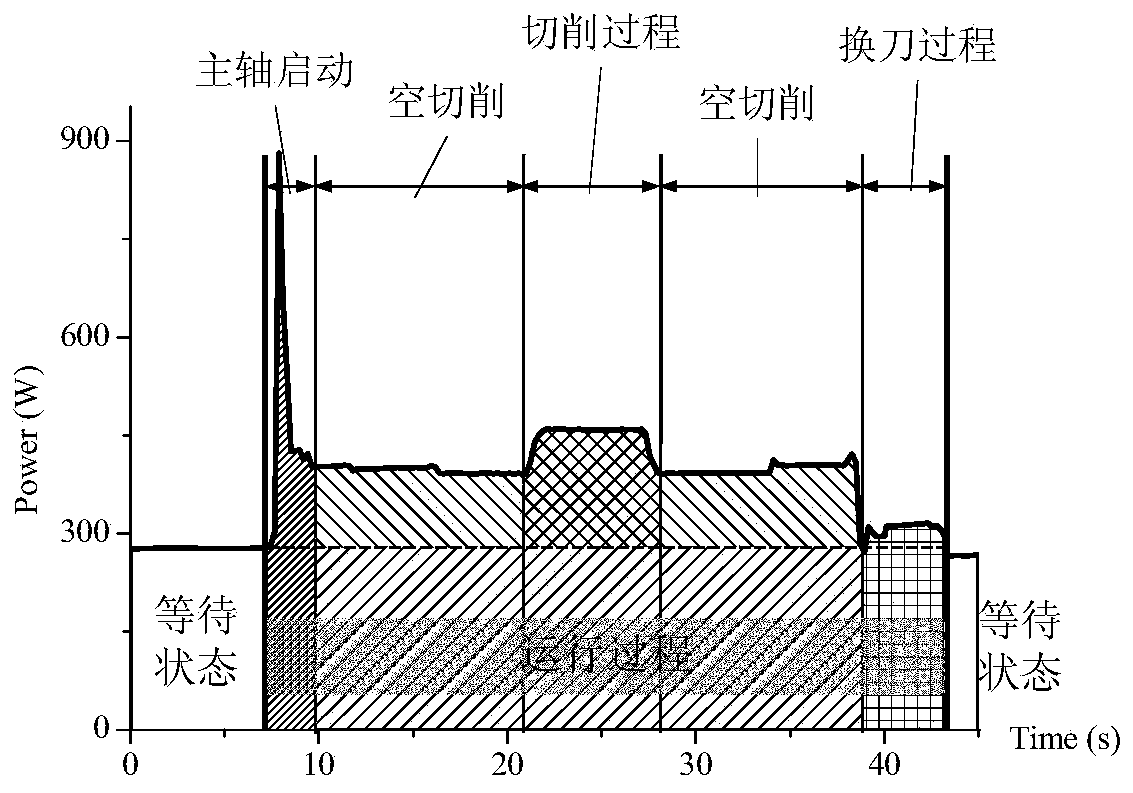

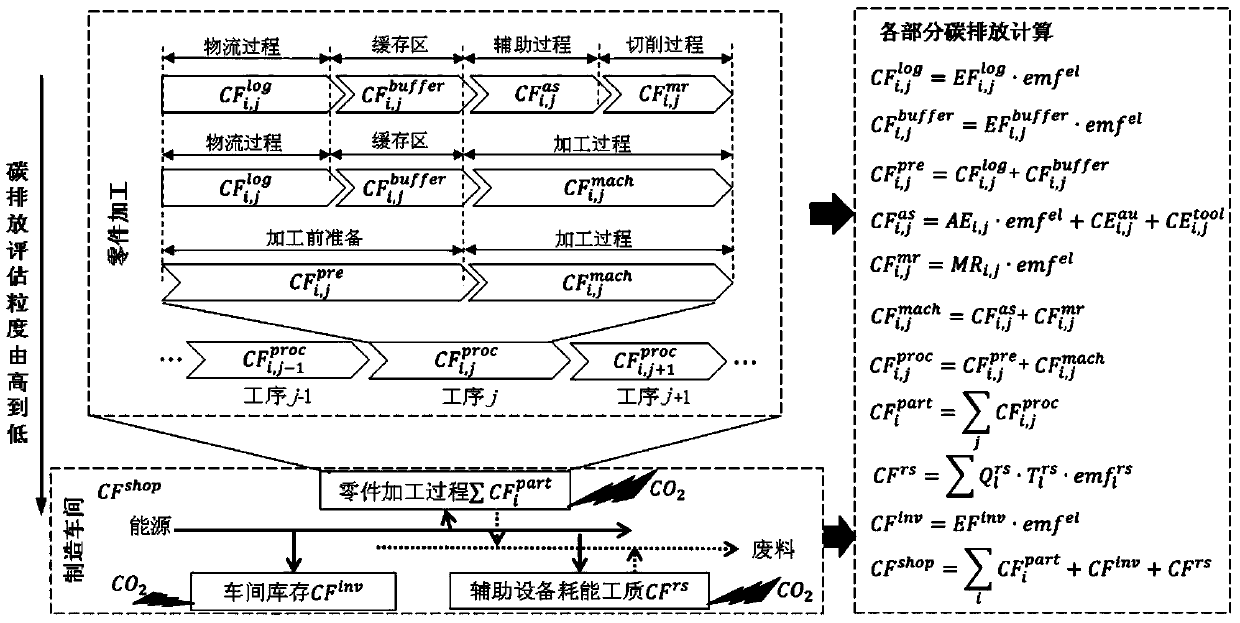

[0025] 1) By analyzing the characteristics of the manufacturing workshop, a schematic description of the manufacturing process of the workshop is established, and from the perspective of energy consumption and carbon emissions in the manufacturing workshop, the manufacturing workshop is decomposed from bottom to top to form the equipment layer, parts layer and workshop layer. Three levels, and then redefine "energy consumption footprint" and "carbon footprint", and based on the whole life cycle assessment method, establish the energy consumption footprint and carbon footprint calculation method of single equipment, single part and the whole workshop ;2) Based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com