Dual-axis mems in-plane high-g sensor based on microbeam detection structure

A detection structure and sensor technology, applied in the field of MEMS sensors, can solve the problems of difficult horizontal acceleration measurement, complex acceleration sensor structure, low sensitivity, etc., and achieve the effects of good resistance to high overload, good sensitivity, and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

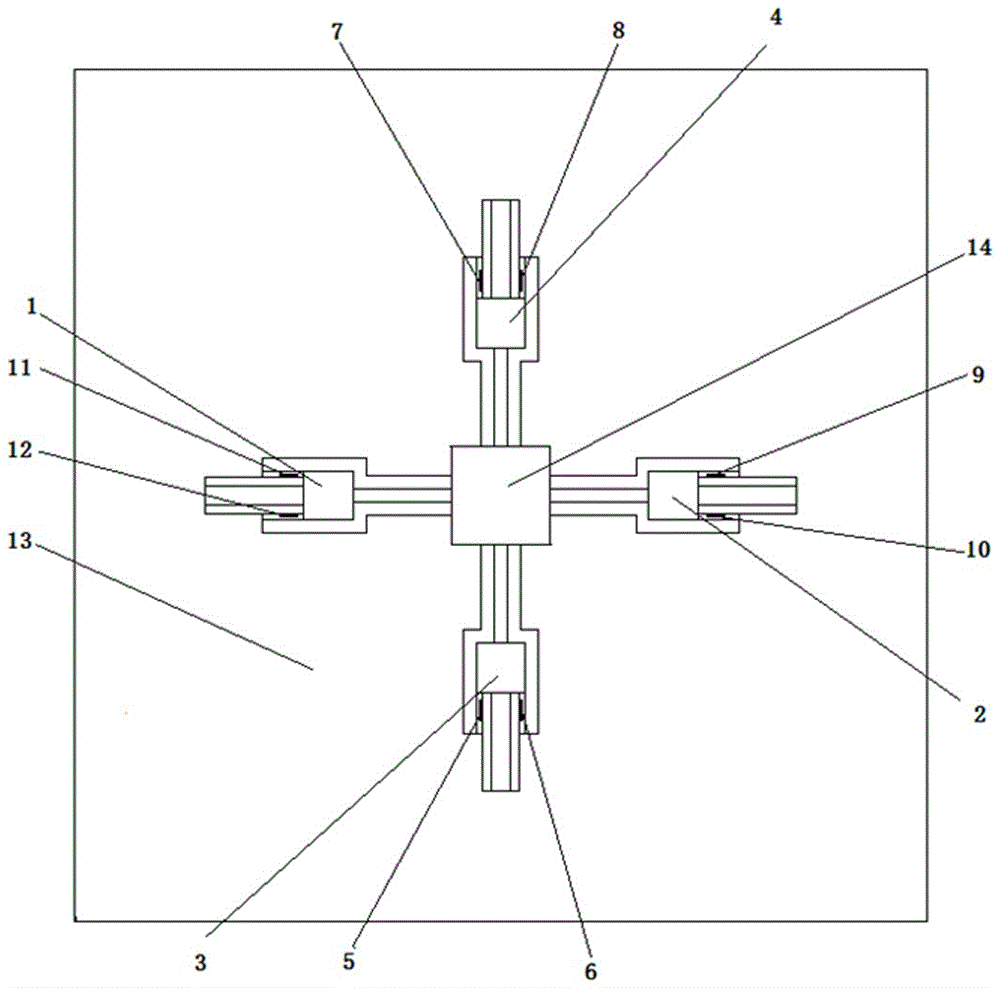

[0016] Such as figure 1 As shown, a kind of biaxial MEMS in-plane high-g sensor based on the micro-beam detection structure provided by the present invention includes a silicon-based support frame and four sensitive structures, and the silicon-based support frame includes a silicon-based frame 13 and is fixedly connected to the silicon-based Anchor block 14 at the center of the surface of frame 13; four sensitive structures are X-1 sensitive structure 1, X-2 sensitive structure 2, Y-1 sensitive structure 3, and Y-2 sensitive structure 4, which are evenly distributed in the center of the anchor block Around, X-1 sensitive structure 1 and X-2 sensitive structure 2 are in the X-axis direction, Y-1 sensitive structure 3 and Y-2 sensitive structure 4 are in the Y-axis direction.

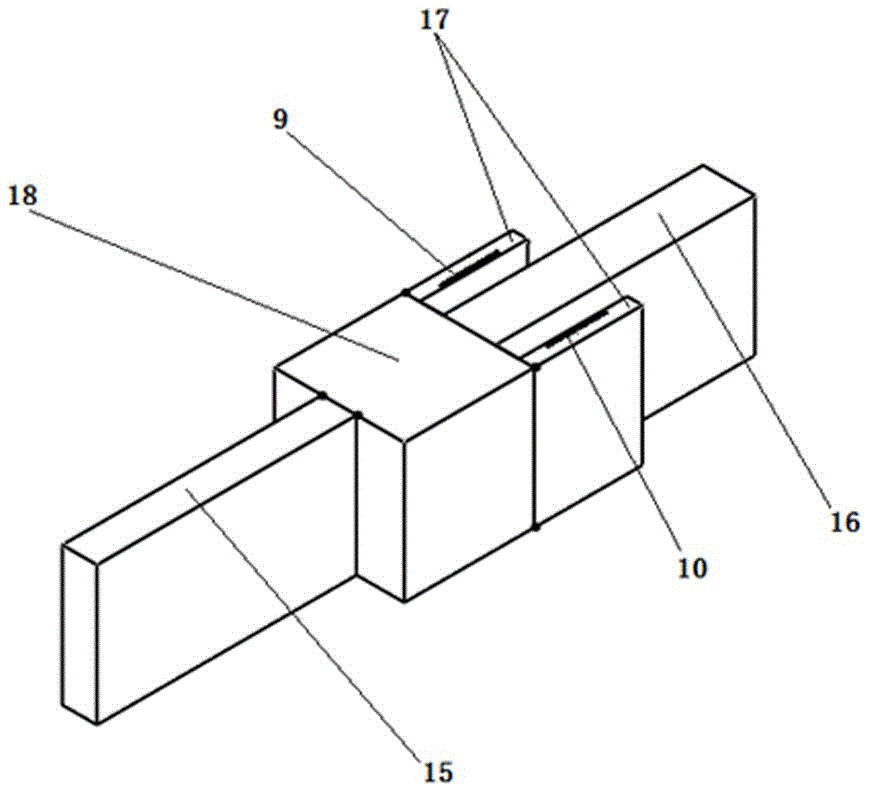

[0017] figure 2 It is a schematic diagram of the X-2 sensitive structure, which is the same as other sensitive structures. Any sensitive structure includes a proof mass 18 and four cantilever beams. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com