A lever type roller scale

A technology of lever-type and roller scales, which is applied in the direction of weighing equipment, measuring devices, and instruments for materials with special properties/forms, and can solve the problems of short service life, weighing impact, and high installation costs of roller scales. Achieve the effects of increased service life, good foundation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

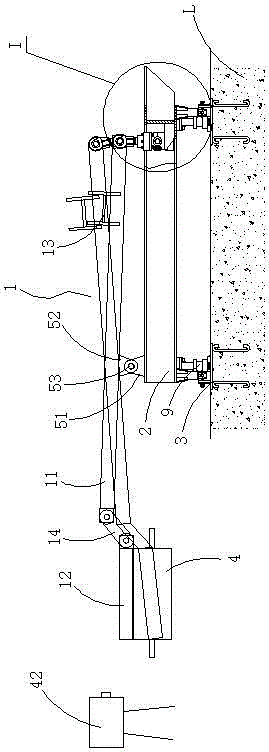

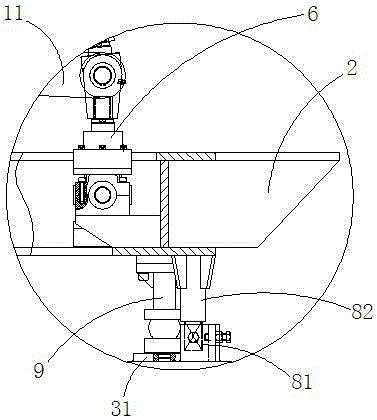

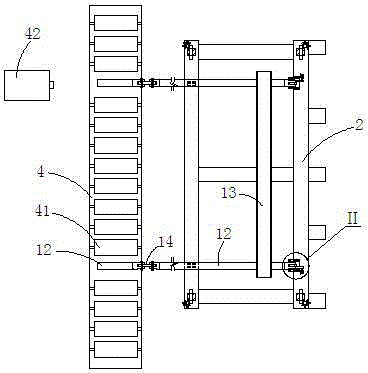

[0028] like Figure 1 to Figure 6 Shown is the structural representation of the present invention,

[0029] The reference signs are: foundation L, upper scale body 1, lever body 11, loading platform 12, reinforcing beam 13, adjustment rod 14, positioning plate 15, lower scale body 2, bracket 3, lower lining plate 31, roller Road 4, roller 41, infrared locator 42, hinge seat 51, hinge body 52, hinge shaft 53, hydraulic cylinder 6, proximity switch 7, proximity switch mounting plate 71, limit block 81, limit block top column 82. Weight sensor 9; the dotted line in the figure shows the position of the upper scale body 1 when the loading platform 12 descends to the lowest point.

[0030] like Figure 1 to Figure 6 as shown,

[0031] A lever-type roller scale, including a scale body, wherein the scale body is composed of an upper scale body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com