A Low Temperature Waste Heat CO2 Rankine Cycle System

A circulation system and low-temperature waste heat technology, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increasing high-power steam turbines, increasing exhaust steam volume flow, and technical infeasibility, etc., to achieve thermal power conversion Efficiency improvement, huge economic benefits, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

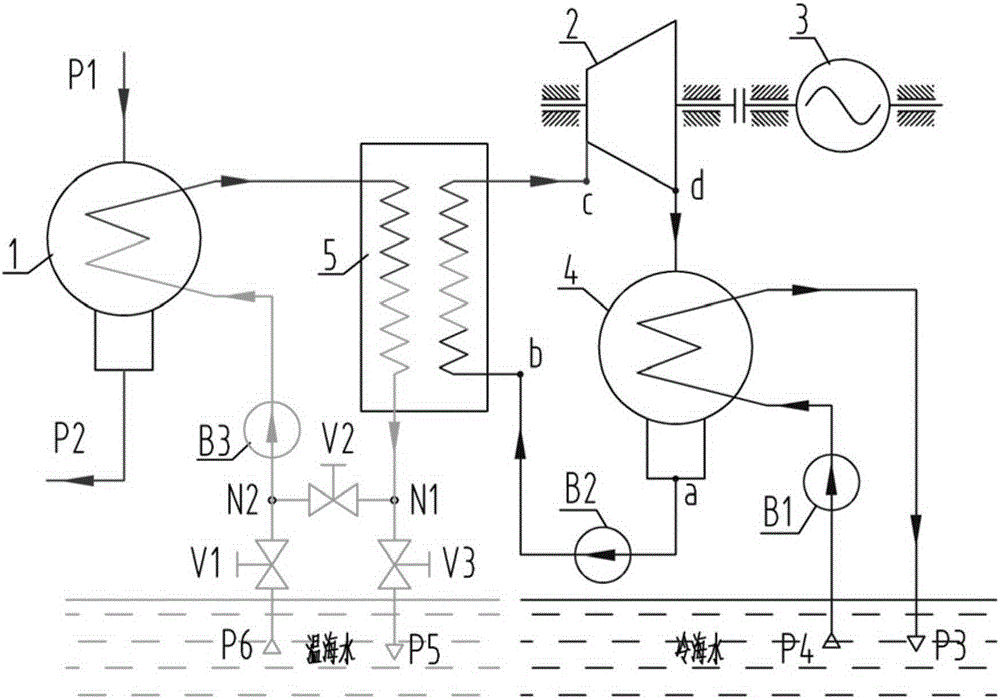

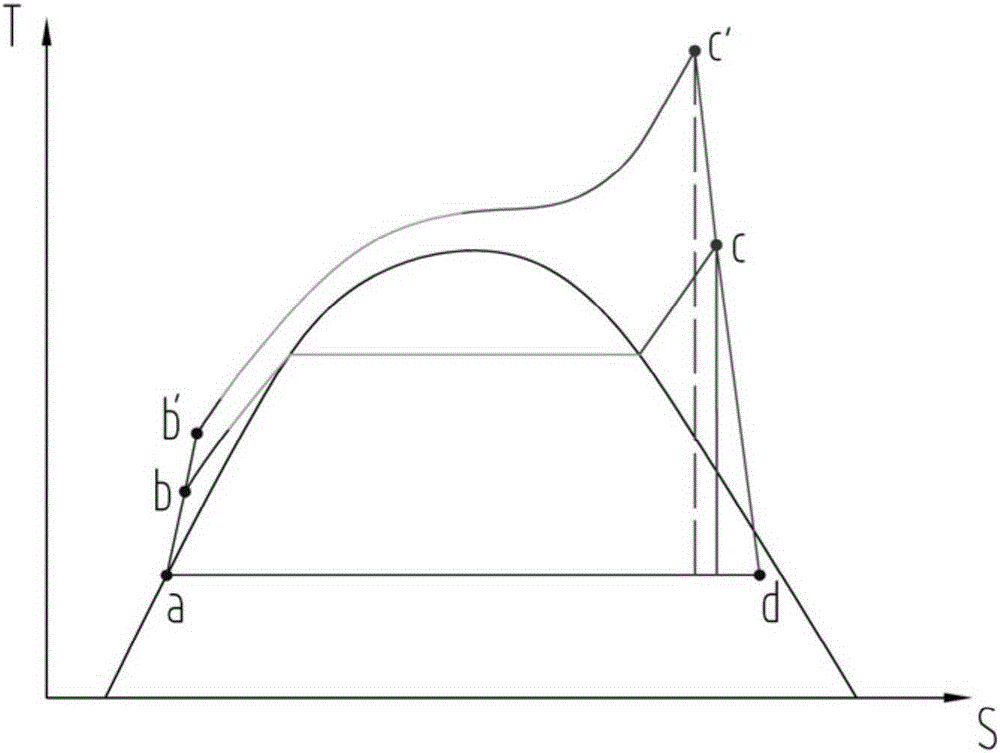

[0029] A CO2 system that utilizes the temperature difference between the warm water discharge from the condenser of an offshore power plant and the seasonal cold seawater in the middle and high latitudes. 2 Rankine cycle system, such as figure 1 As shown, take the power plant condenser warm water as CO 2 Circulating heat source, the seasonal coastal cold seawater in middle and high latitudes is CO2 2 Circulating cold source. The circulation system mainly includes power plant condenser 1, CO 2 Turbine 2, generator or power consumption equipment 3 (power consumption equipment includes pumps, fans, etc.), CO 2 Circulating condenser 4, heat exchanger 5, cold water pump B1, CO 2 Circulating booster pump B2 and power plant condenser circulating water pump B3, etc. The circulatory system can be decomposed into the following three loops:

[0030] Heat source loop: When the temperature difference between the cold source and the heat source exceeds 10°C and the temperature of the ...

Embodiment 2

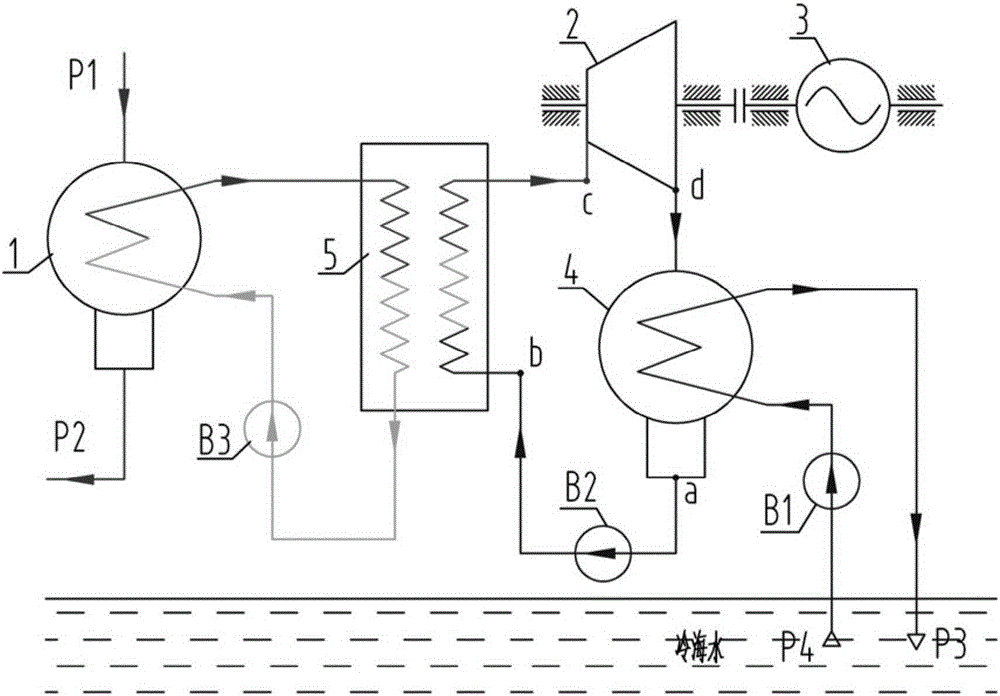

[0036] A CO2 that utilizes the temperature difference between the warm water discharged from the condenser of an offshore power plant and the cold seawater in the offshore 2 Rankine cycle system, such as image 3 As shown, take the power plant condenser warm water as CO 2 Circulating heat source, the seasonal coastal cold seawater in middle and high latitudes is CO2 2 Circulating cold source. CO in the circulatory system 2 The circuit and the cold source circuit are exactly the same as in Embodiment 1, while the heat source circuit is simpler than in Embodiment 1, and the first control valve V1, the second control V2, the third control V3, and the power plant condenser cooling water outlet P5 and Power plant condenser cooling water inlet P6. The circulation system is mainly used in offshore seawater temperature is always lower than CO 2 For power plants with critical temperature, when the temperature difference between the cold source and the heat source is small, the exh...

Embodiment 3

[0039] A CO2 system that utilizes the temperature difference between the exhaust steam of the steam turbine in the offshore power plant and the cold seawater in the offshore 2 Rankine cycle system, such as Figure 4 As shown, taking the exhaust steam of the steam turbine in the power plant as the CO 2 Circulating heat source, the seasonal coastal cold seawater in middle and high latitudes is CO2 2 Circulating cold source. The field of application of the circulatory system is exactly the same as in Example 2, but the heat exchanger 5 is canceled and the CO 2 The working fluid directly exchanges heat with the exhaust steam of the steam turbine, and only CO 2 The circuit and the cold source circuit are further simplifications of Embodiment 2, and the working principle of the cold source circuit is the same as that of Embodiment 2, and will not be repeated here.

[0040] CO 2 Loop: from CO 2 High pressure CO of circulating booster pump B2 2 The liquid (state point b) enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com