Compression ratio adjustable engine suitable for arbitrary crank overlap without destroying the crankshaft structure

An engine and overlap technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of reduced crank overlap, reduced torsional stiffness of transmission parts, increased accelerated wear, etc. The effect of reliable load capacity and strong gear load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The adjustable compression ratio engine suitable for any crank overlapping degree without destroying the crankshaft structure of the present invention will be described in detail below with reference to the embodiments and accompanying drawings.

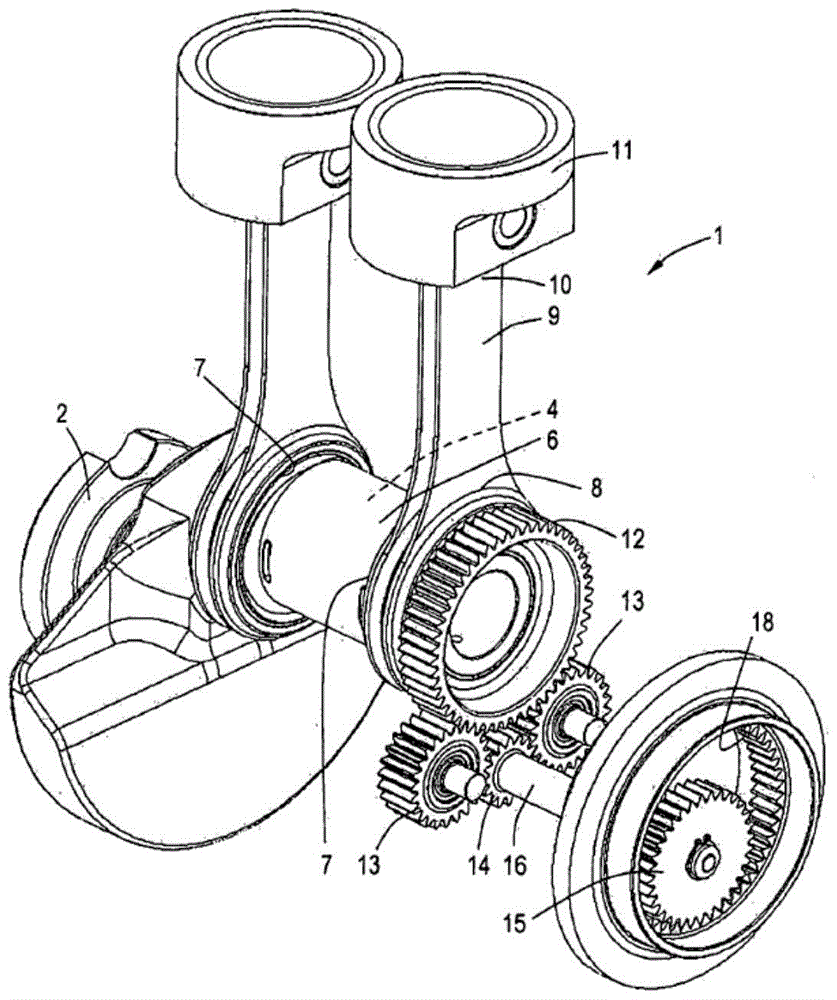

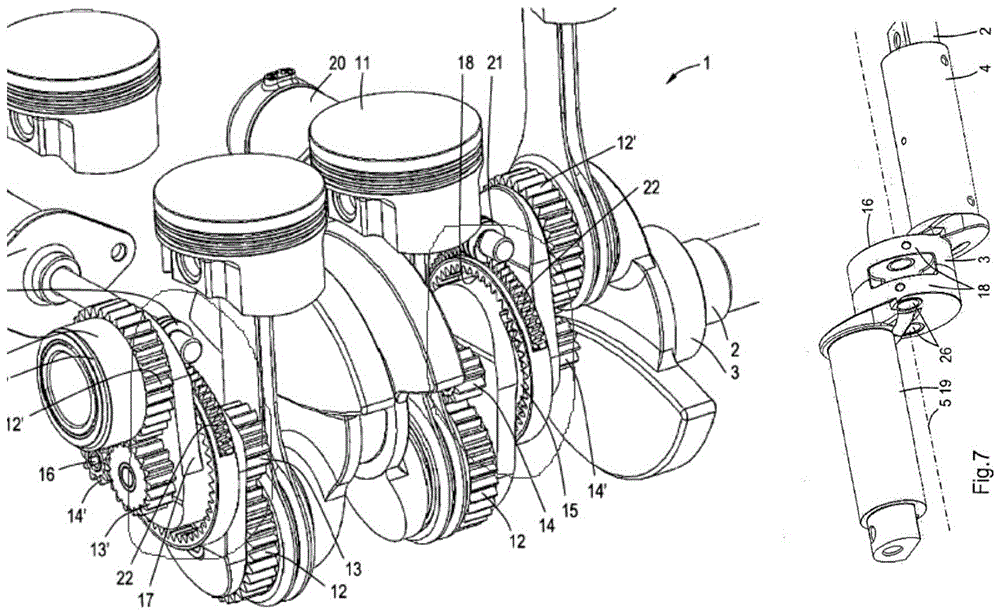

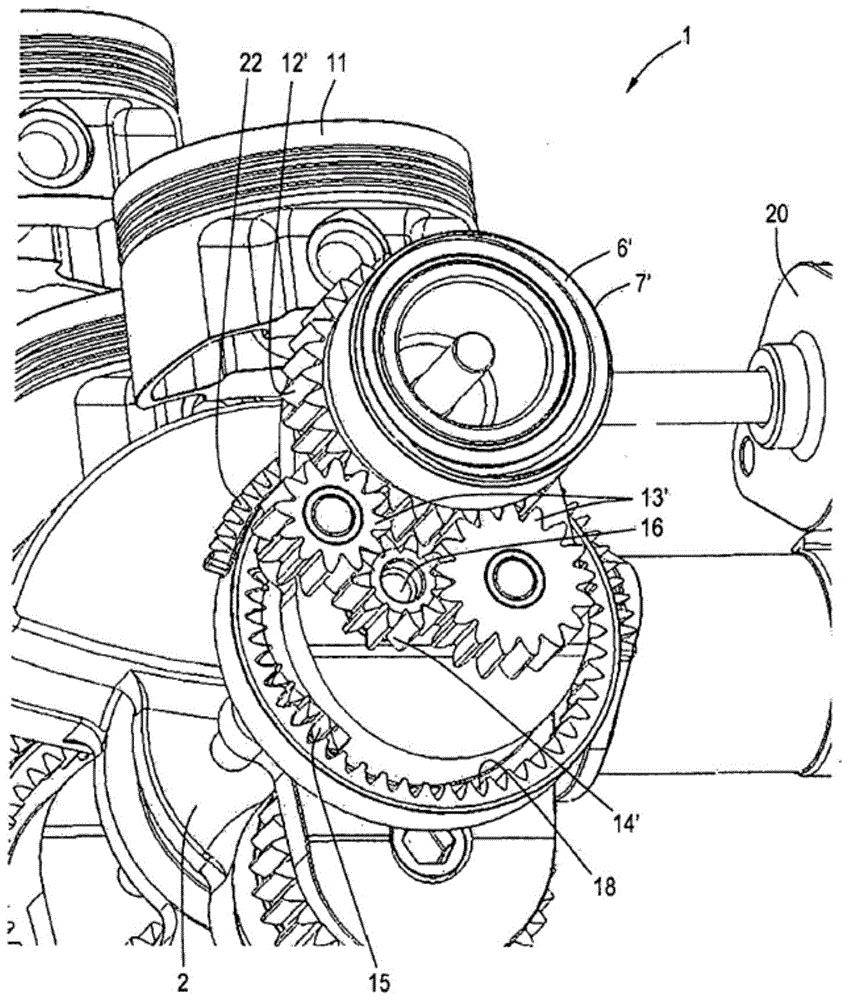

[0045] Such as Figure 4 , Figure 5 , Figure 6 , Figure 9 As shown, the non-destructive crankshaft structure of the present invention is suitable for an adjustable compression ratio engine with any degree of crank overlap, including at least one first cylinder 2, and the reciprocating piston 1 located in the first cylinder 2 runs through the first cylinder 2 And the upper end of the connecting rod 3 in the first cylinder 2 is hinged by the piston pin 32, and the other end of the connecting rod 3 stretches out from the lower side of the first cylinder 2 and is hinged to the drive mechanism positioned below the first cylinder 2, the drive mechanism It includes a crankshaft composed of the main journal 24, the first crank a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com