Moving type asphalt mixture regeneration equipment

A technology of asphalt mixture and recycling equipment, applied in roads, road repairs, roads, etc., can solve problems such as environmental pollution, quality impact, fuel waste, etc., achieve the effect of flexible and easy operation, and improve heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

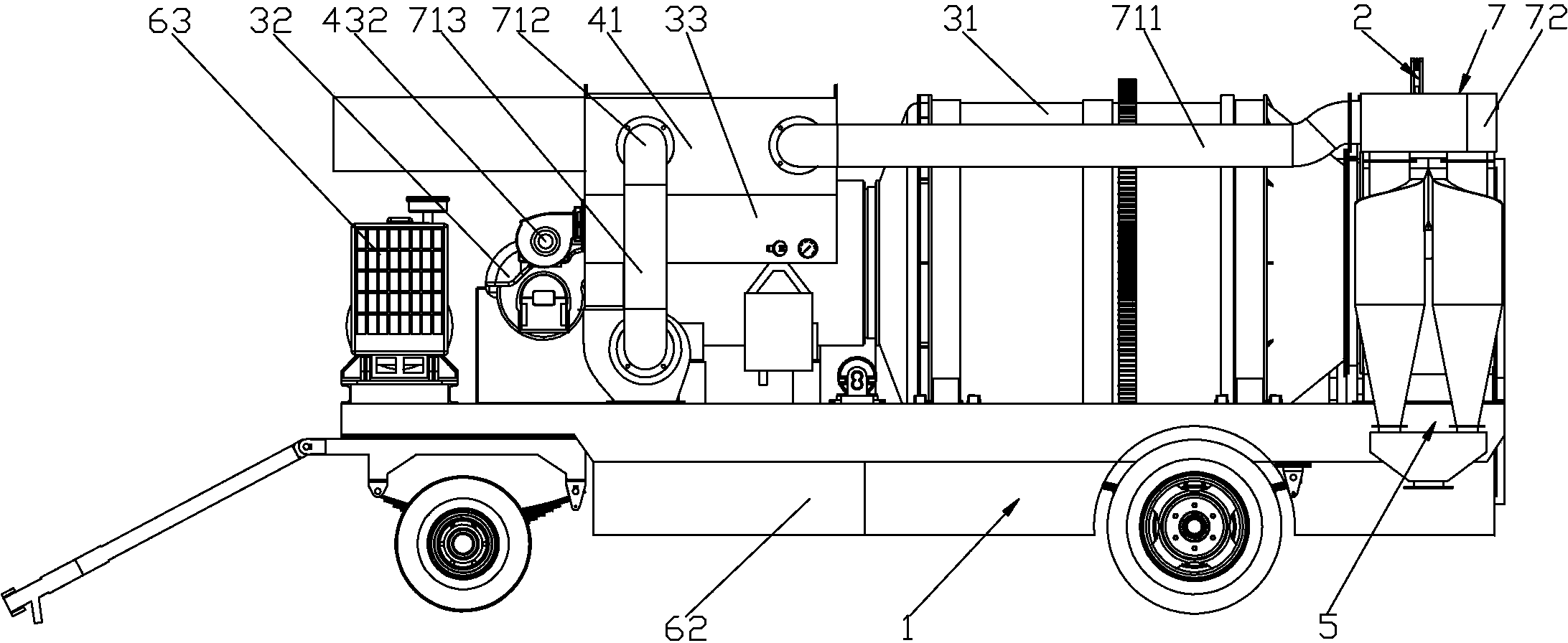

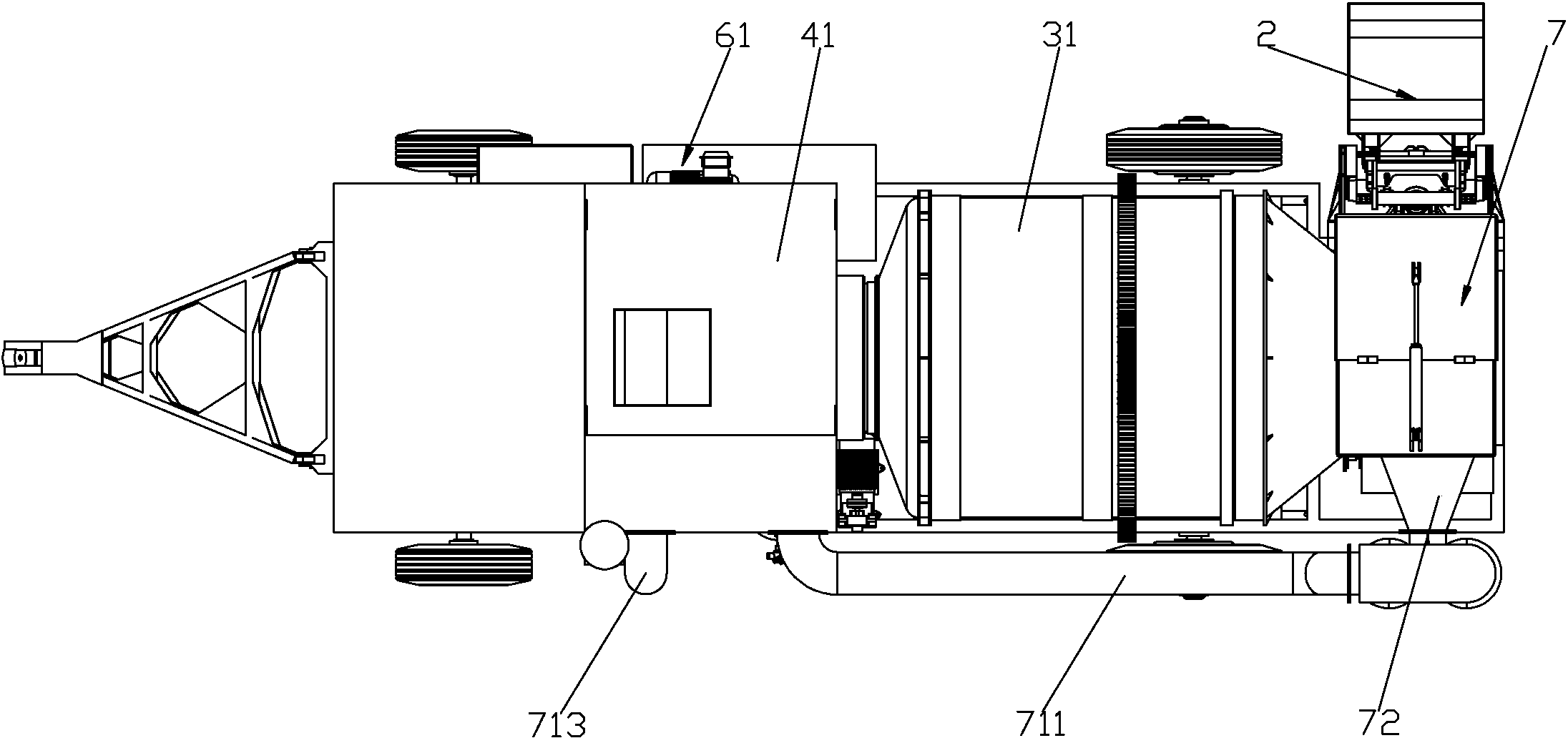

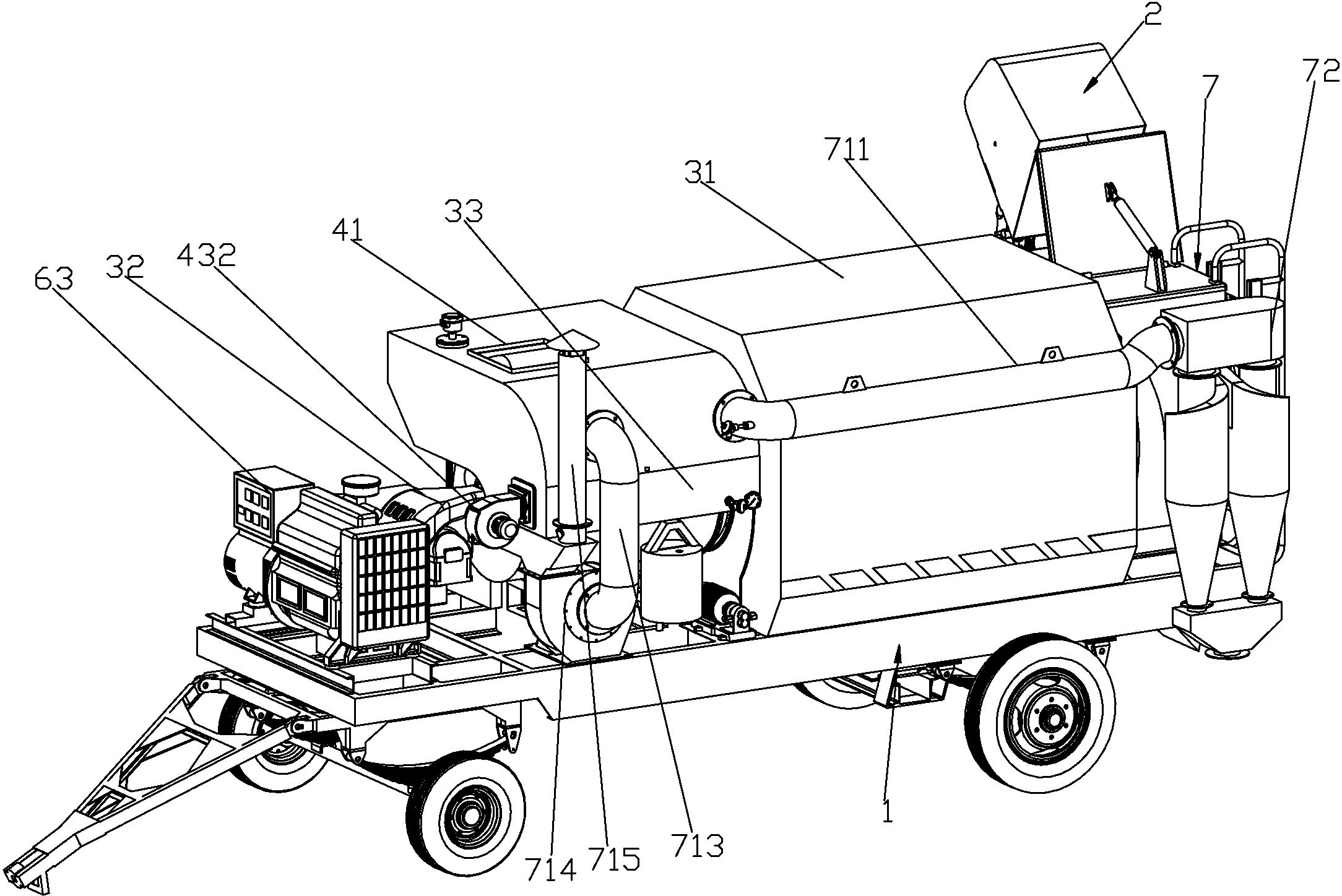

[0030] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a mobile asphalt mixture recycling equipment includes a tractor and a semi-trailer frame 1, and an asphalt storage device, a drying and heating device, a stirring device 5, and an air induction device are installed above the semi-trailer frame 1. Dust removal device 7 and a control device for controlling the above-mentioned components. The control device includes a hydraulic device 61, a diesel tank 62, a generator set 63 and an electro-hydraulic control device (not shown in the figure); the generator set 63 can satisfy the self-power supply of the mobile asphalt mixture regeneration equipment; the drying and heating device includes The main burner 32, the hot blast stove 33 and the drying and heating drum 31 are connected in sequence. Asphalt storage device comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com