An electromagnetic ironing machine

An electromagnetic ironing machine and ironing machine technology, applied in the direction of hand irons, washing devices, textiles and papermaking, etc., can solve the problems of low thermal efficiency, heat loss, heating of ironing devices, etc., to reduce heat consumption and avoid condensation , the average temperature and the effect of small differences in external

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

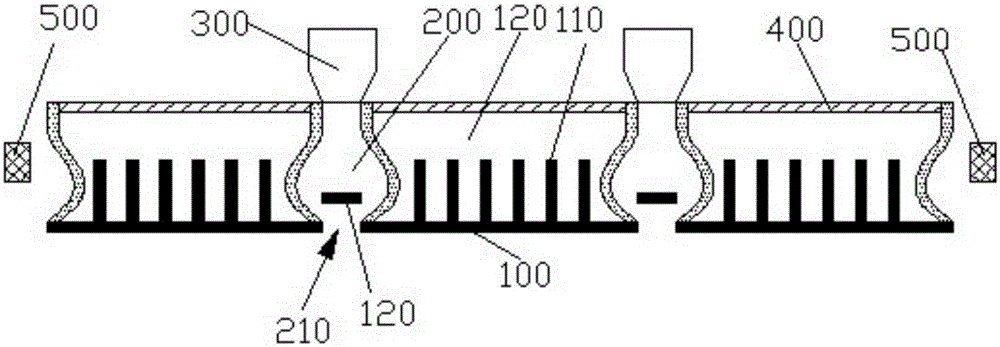

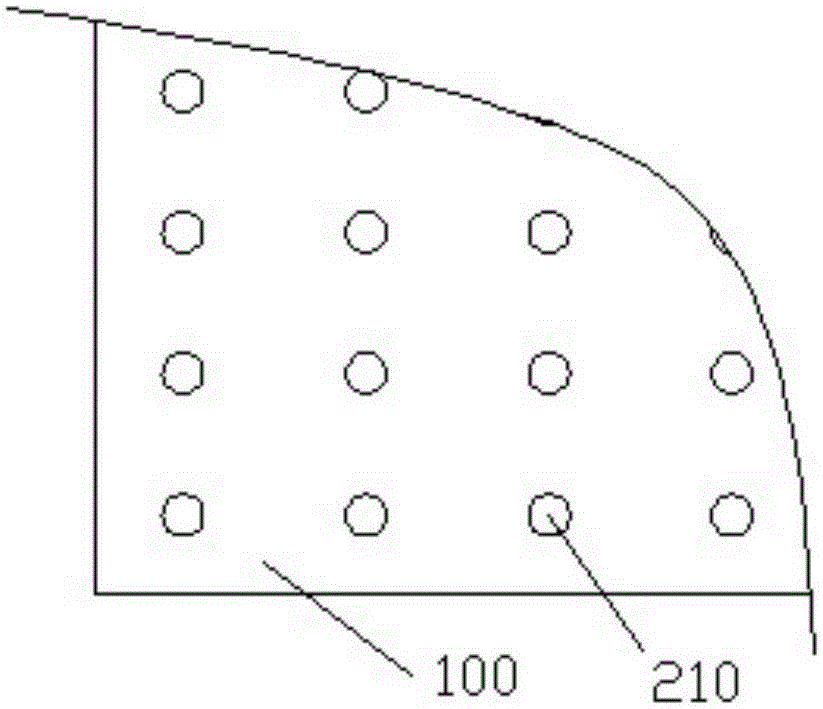

[0014] In this example, see figure 1 and figure 2 , the electromagnetic ironing machine includes a metal ironing board 100, the metal ironing board 100 is evenly opened with air outlets 210, the upper side of the metal ironing board 100 is provided with a cover covering the upper surface of the metal ironing board 100 400, the cover body 400 is provided with a water inlet and a water outlet, and the cover body 400 is provided with an air passage 200 matching with the air outlet hole, and the air passage 200 is provided with a water outlet parallel to the air outlet hole 210. And the metal heating sheet 120 of the same size and shape, the top of the air channel 200 is provided with an atomizing nozzle 300 pointing to the metal heating sheet 120, the atomizing nozzle 300 is connected with the water outlet, and the cover A high-frequency electromagnetic coil 500 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com