A device and method for high-efficiency dedusting of biomass rapid pyrolysis steam

A technology of biomass and steam, which is applied in the direction of chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of fluctuating air volume, inability to effectively remove dust removal effect of particles, and instability, so as to reduce dust removal load and dust removal effect The effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described below with reference to the accompanying drawings.

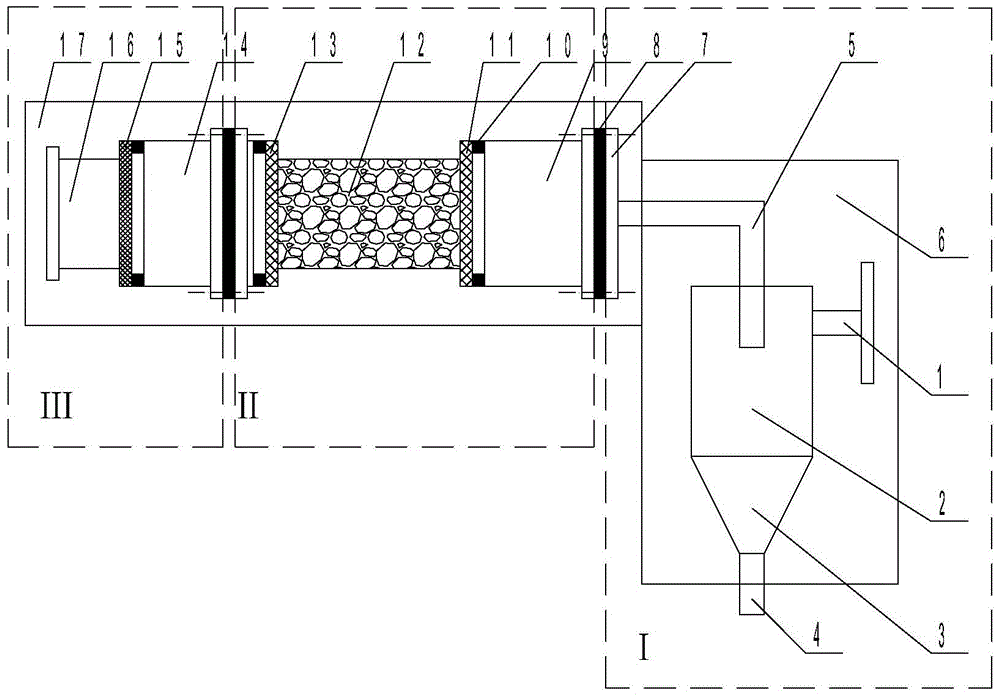

[0024] A device for high-efficiency dedusting of biomass rapid pyrolysis steam, including cyclone dust collector I, particle layer dust collector II and metal mesh dust collector III connected in sequence according to the flow direction of pyrolysis steam, and a first electric dust collector is arranged outside the cyclone dust collector The outside of the heating furnace, granular layer dust collector and metal mesh dust collector is equipped with a second electric heating furnace, the first electric heating furnace and the second electric heating furnace maintain the cyclone dust collector, granular layer dust collector and metal mesh dust collector and the entire front and back The pyrolysis steam temperature in the steam pipeline is 400-600°C. Between the cyclone dust collector and the granular layer dust collector, and between the granular layer dust collector and the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com