Energy-saving double-circulation unpowered automatic mixing Fenton reactor

A reactor, double-circulation technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of immobility, large area of the reaction tank, inconvenient sewage treatment, etc., to achieve compact structure, small footprint, and reduced equipment costs. and the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

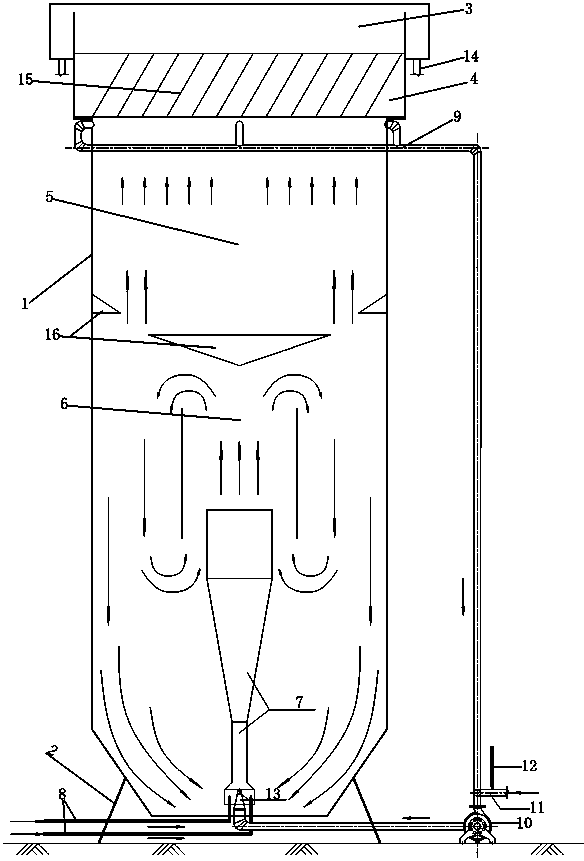

[0011] Such as figure 1 As shown, a kind of energy-saving dual-circulation unpowered automatic mixing Fenton reactor described in the present invention includes a reactor shell 1, a base 2 supporting the entire reactor shell 1 and an inlet pump 10, and the top of the reactor shell 1 is A water outlet weir 3 is provided, and a reaction precipitation chamber 4, a reaction chamber 5, and a mixing reaction chamber 6 are sequentially arranged in the reactor shell 1 from top to bottom, and a diffusion system 7 is arranged in the mixing reaction chamber 6, and the bottom of the reactor shell 1 is provided with The dosing pipe 8 extends into the diffusion system 7; the two shell walls of the reaction chamber 6 are provided with an external return pipe 9, and is connected with the water inlet pump 10; The pipe 9 communicates, and the acid pipe 12 is provided on the water inlet pipe 11; the injection system 13 is also provided between the water inlet pump 10 and the diffusion system 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com