Preparation method of electronic grade hydrofluoric acid

An electronic grade hydrofluoric acid, hydrofluoric acid technology, applied in the direction of fluorine/hydrogen fluoride, etc., can solve the problems of no tail gas recovery, increased burden, etc., and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

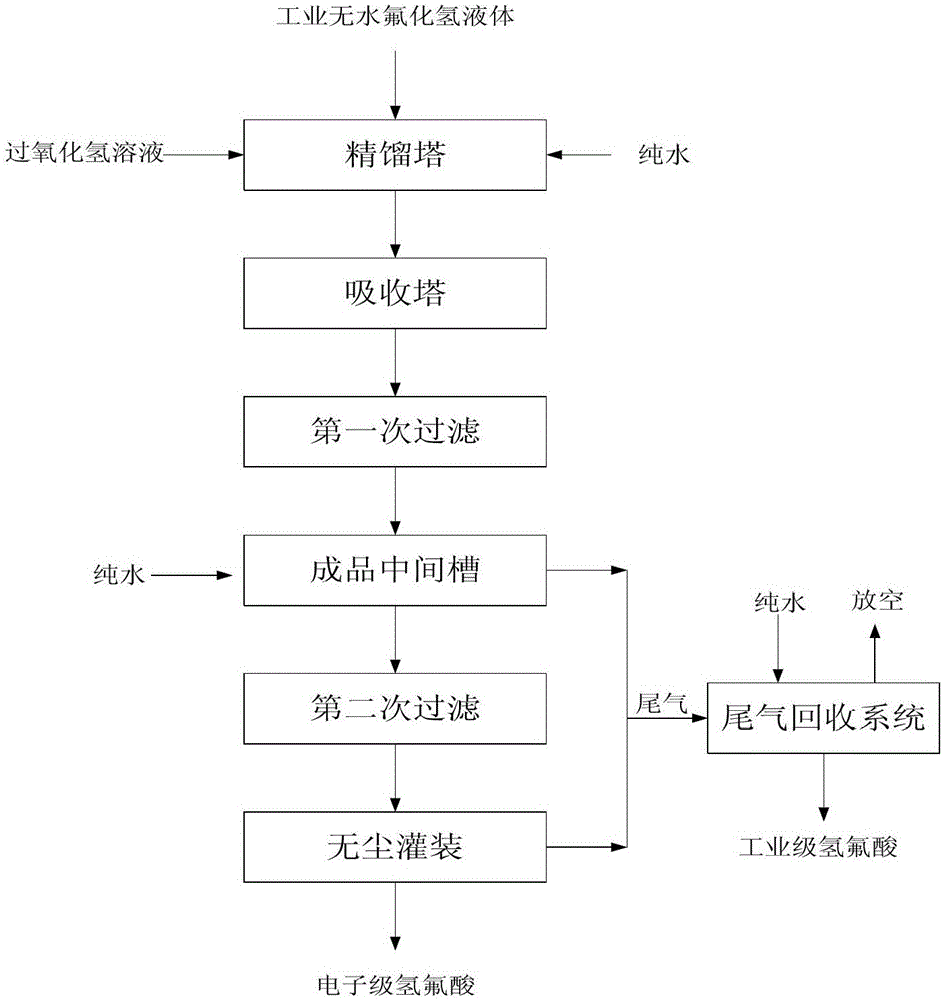

[0044] Such as figure 2 Shown, method of the present invention specifically comprises the following steps:

[0045] 1) Put the industrial anhydrous hydrogen fluoride liquid and pure water into the rectification tower respectively through the metering pump, mix well to form hydrofluoric acid with the first concentration (60% by mass fraction), and then add peroxide with a mass fraction of 50% Hydrogen is oxidized to oxidize impurities such as arsenic and silicon, and then rectified to obtain purified hydrogen fluoride gas at the top of the rectification tower, and the impurities remain in the bottom of the tower.

[0046]Among them, the amount of hydrogen peroxide solution is 0.04% of the mass of industrial anhydrous hydrogen fluoride liquid; in the oxidation treatment process, pump circulation is supplemented to mix hydrogen fluoride and hydrogen peroxide solution evenly, and the oxidation time is 7.5 hours; The temperature of the tower is 26°C, the temperature of the tower ...

Embodiment 2

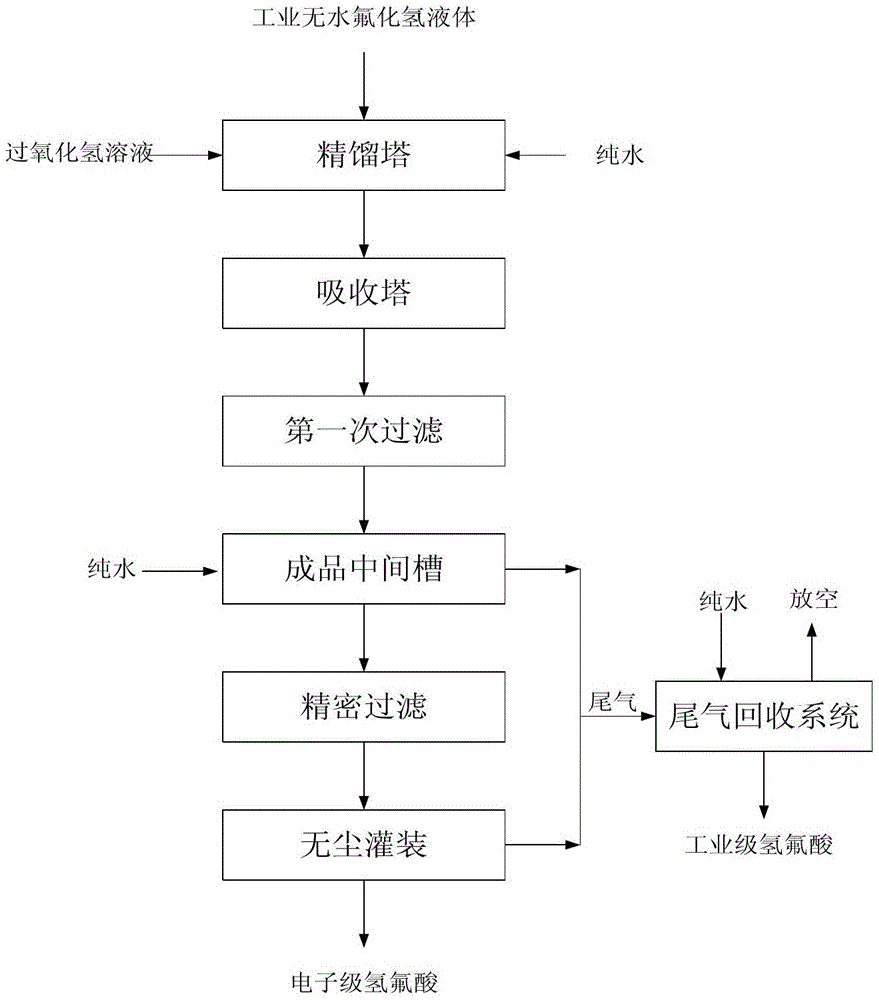

[0054] Such as image 3 Shown, method of the present invention specifically comprises the following steps:

[0055] 1) Add the industrial anhydrous hydrogen fluoride liquid and pure water into the rectification tower respectively through the metering pump, mix well to form hydrofluoric acid with the first concentration (70% by mass fraction), and then add peroxide with a mass fraction of 50% The hydrogen solution is oxidized to oxidize impurities such as arsenic and silicon, and then rectified to obtain purified hydrogen fluoride gas at the top of the rectification tower, and the impurities remain in the bottom of the tower.

[0056] Wherein, the amount of hydrogen peroxide solution is 0.03% of the mass of industrial anhydrous hydrogen fluoride liquid; in the oxidation treatment process, pump circulation is supplemented to make hydrogen fluoride and hydrogen peroxide solution mix evenly, and the oxidation time is 6 hours; 26°C, tower body temperature 18.5°C, tower top tempera...

Embodiment 3

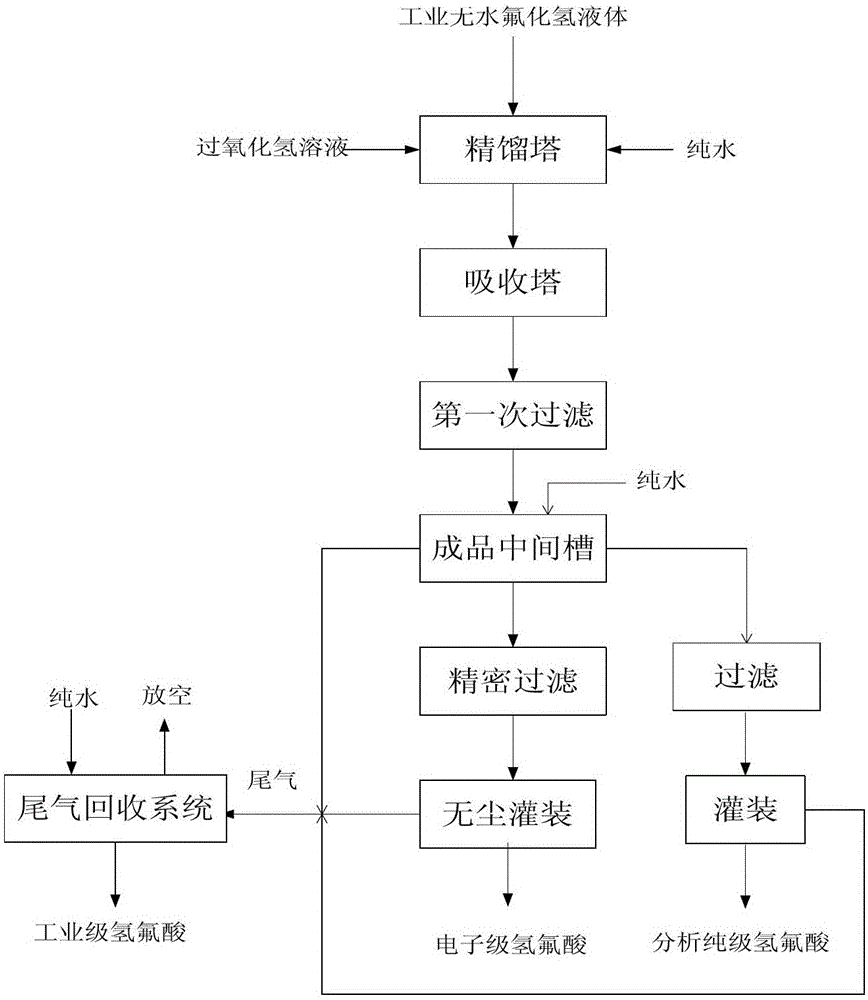

[0065] Such as image 3 Shown, method of the present invention specifically comprises the following steps:

[0066] 1) Add industrial anhydrous hydrogen fluoride liquid and pure water into the rectification tower respectively through metering pumps to form hydrofluoric acid at the first concentration (65% by mass fraction), and then add hydrogen peroxide with 45% mass fraction to carry out Oxidation treatment, oxidizing impurities such as arsenic and silicon, and then performing rectification to obtain purified hydrogen fluoride gas at the top of the rectification tower, and the impurities remain in the bottom of the tower.

[0067] Among them, the dosage is 0.03% of the mass of industrial anhydrous hydrogen fluoride liquid; in the oxidation treatment process, pump circulation is supplemented to mix hydrogen fluoride and hydrogen peroxide solution evenly, and the oxidation time is 7 hours; The temperature of the body is 19.5°C, the temperature at the top of the tower is 19°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com