Improved semi-automatic internal grinder

An internal grinding machine, semi-automatic technology, applied in the direction of grinding machine, grinding feed motion, machine tool designed for grinding the rotating surface of the workpiece, etc., can solve the problem of damage to the feeding channel device, unable to realize the feeding process, unable to lift smoothly Bearing ring and other problems, to achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

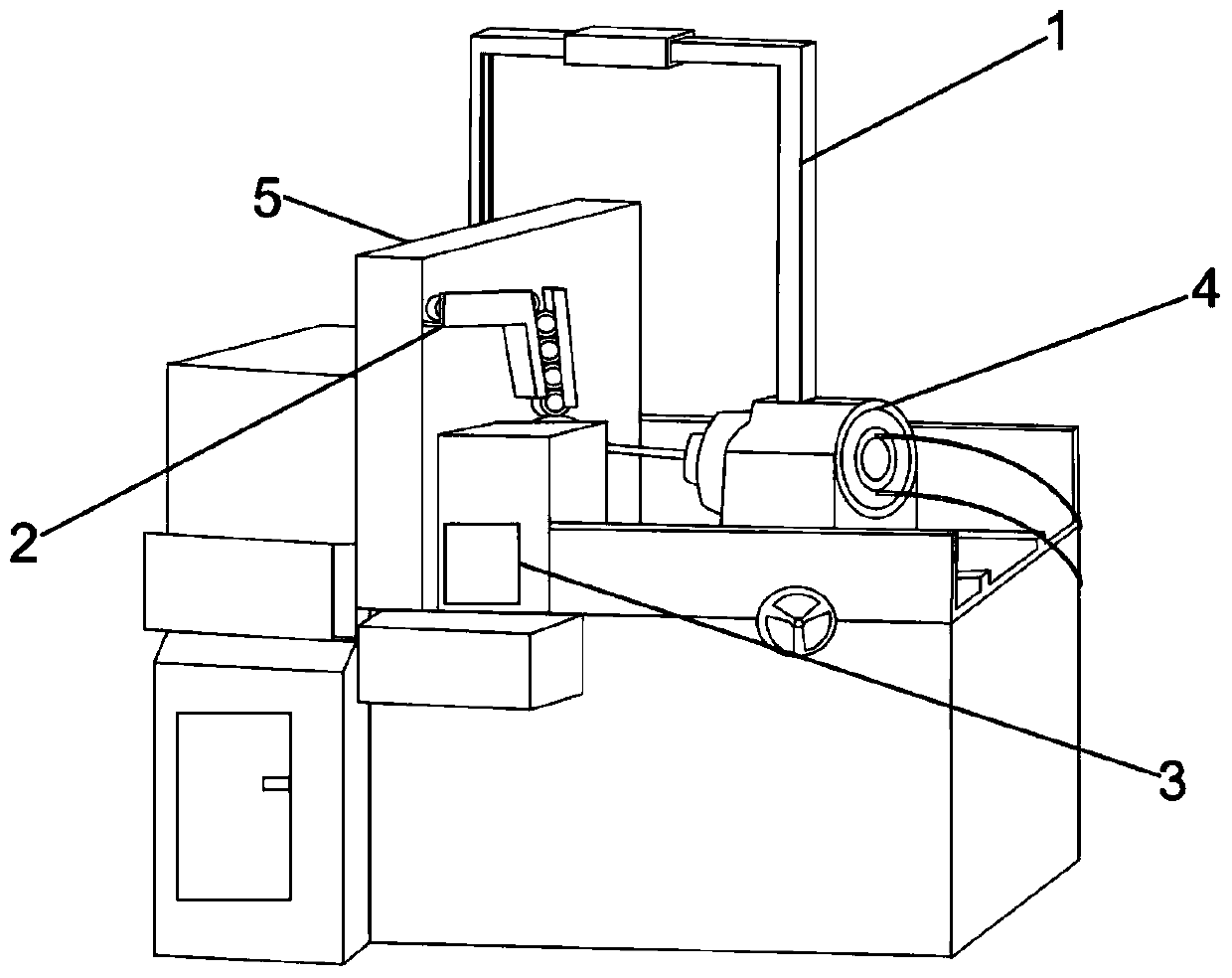

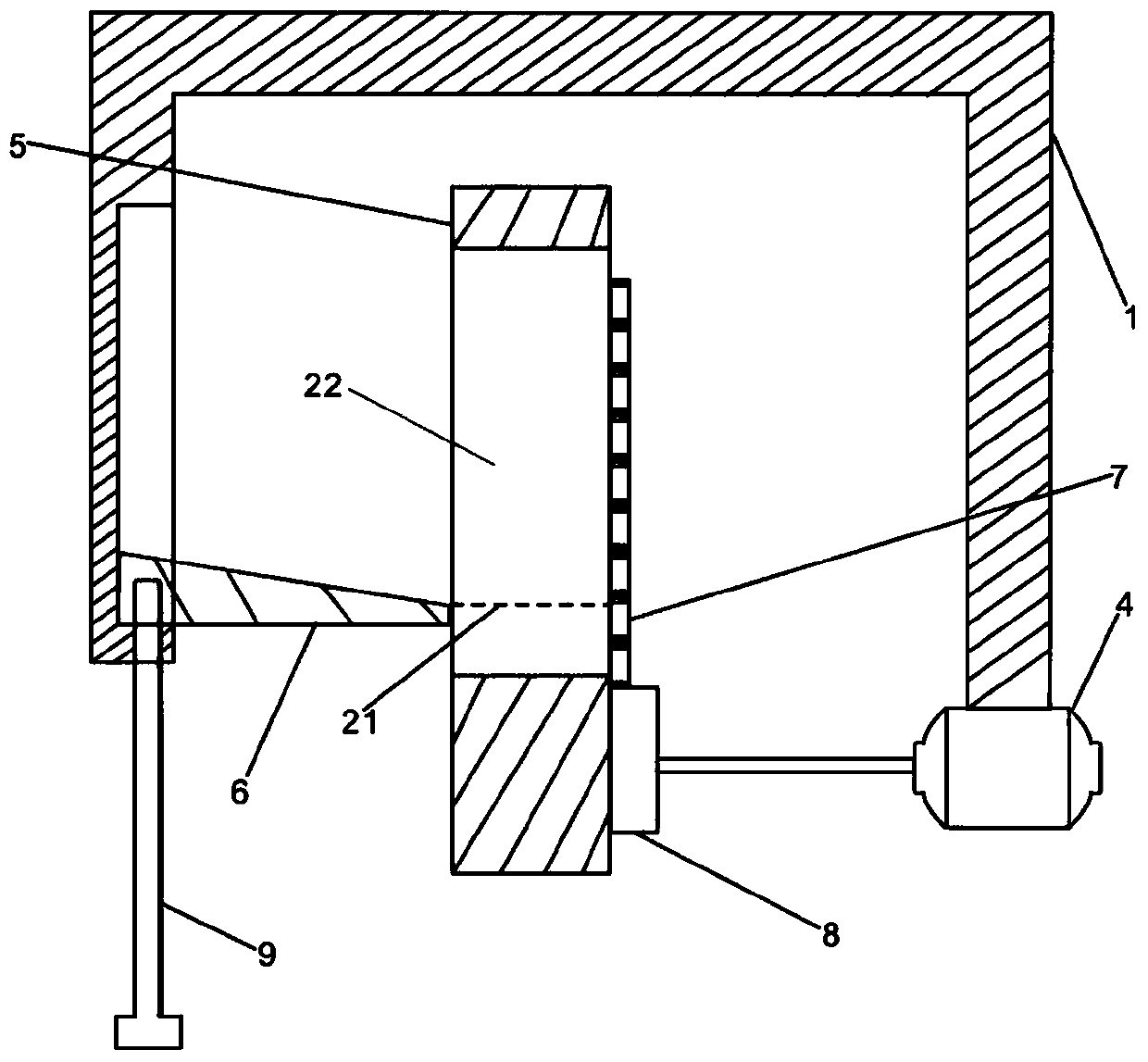

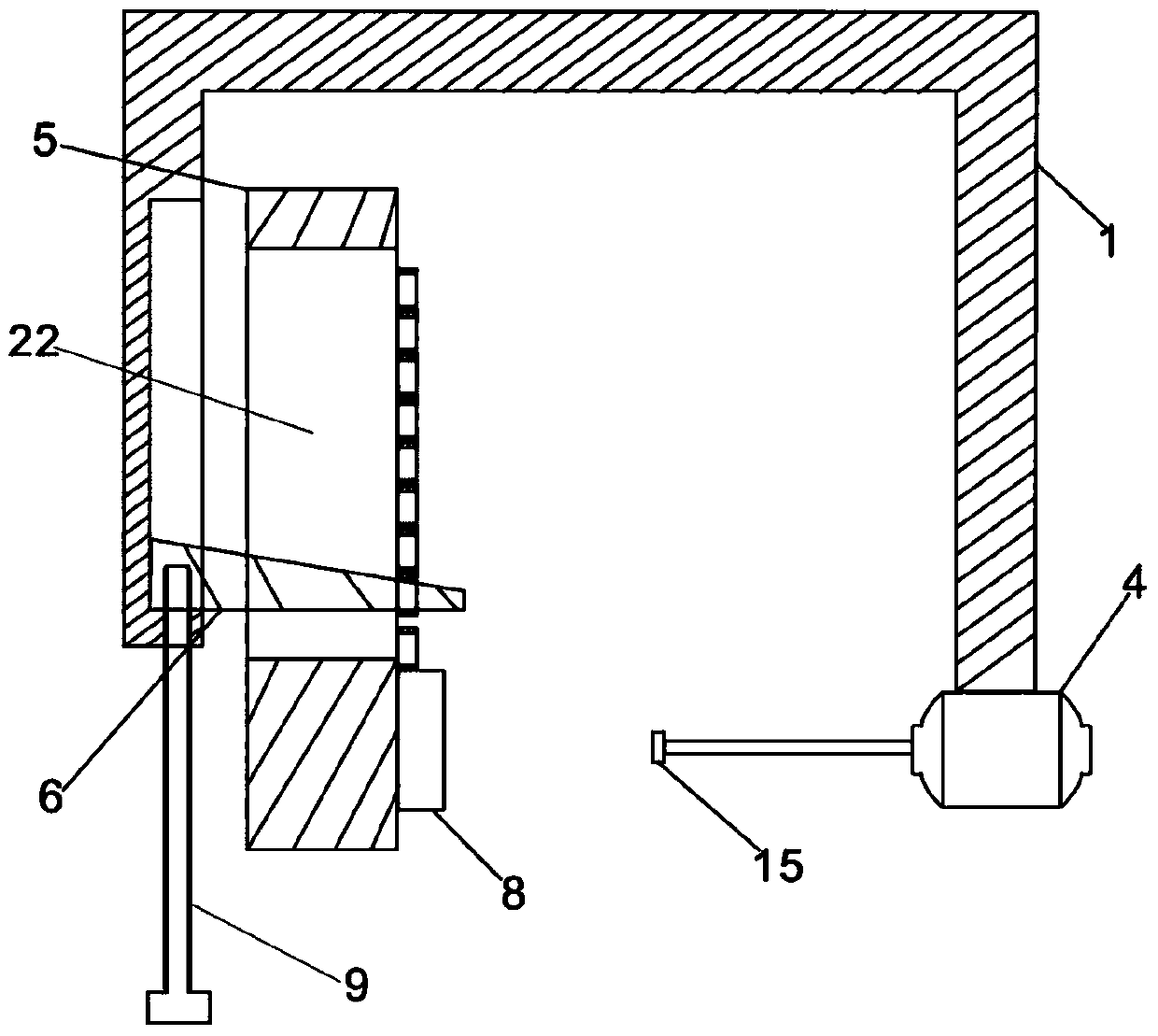

[0027] Embodiment 1: as figure 1 with image 3 As shown, an improved semi-automatic internal grinding machine includes a power device 4 and a retaining wall 5, the power device 4 is connected with a grinding wheel 15, and the power device can move back and forth along the guide rail in the direction of the feeding channel. The right side wall of the retaining wall 5 is provided with a feeding channel 2, such as Image 6 As shown, the feeding channel includes a horizontal feeding channel 13 and a vertical feeding channel 14 . Such as figure 2 with image 3 As shown, a gap 22 is provided on the blocking wall 5 corresponding to the position of the vertical feeding channel.

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the power unit 4 is provided with a rod frame 1, and the rod frame 1 is composed of two vertical rods 11, 12 and a transverse rod 10, and the vertical rod 11 is fixed on the right side of the feeding channel. On the power unit 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com