Welding jig for spiral line of traveling-wave tube

A welding jig and helix technology, applied in the field of traveling wave tube welding jig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

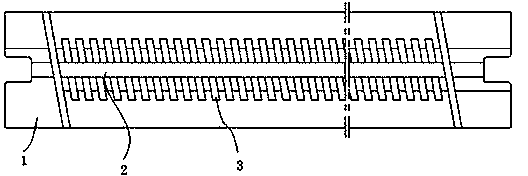

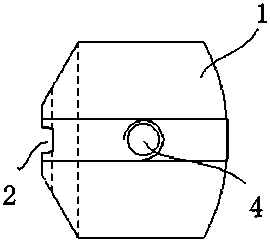

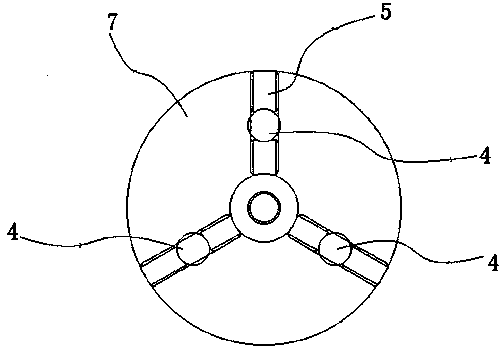

[0025] The traveling wave tube helical wire welding fixture described in this embodiment includes a positioning block, a positioning plate, a spacer, and a screw; the positioning block is three cylinders with central angles of 120° cut by a cylinder, The 120° center of the positioning block is provided with a slow-wave transition strip fixing groove and a plurality of spacer fixing grooves upward along the positioning block axis, and the spacer fixing grooves are parallel to each other and intersect with the slow-wave transition strip fixing groove , the angle between the fixed groove of the spacer and the fixed groove of the slow wave transition strip is consistent with the clamping angle between the slow wave transition strip of the traveling wave tube and the helix; the spacer is placed in the fixed groove of the spacer; the Both ends of the positioning block and the positioning plate are provided with threaded holes and / or pin holes, and the positioning plate can be fixed a...

Embodiment 2

[0028] The second embodiment is to add a base on the basis of the traveling wave tube helical wire welding fixture described in the first embodiment, and the base is provided with a groove matching the shape of the positioning block, and the positioning block can be placed on the base To facilitate the installation of the positioning block and place the fixed positioning block on the base and then put it into the hydrogen furnace for heating and welding.

[0029] Using the traveling wave tube helical wire welding jig described in this embodiment can effectively and reliably weld multiple clamping blocks with the designed clamping angle with the helical wire and the slow wave transition strip, so that the helical wire assembly and welding process is simple and easy to operate . The traveling wave tube welded by the traveling wave tube helical wire welding fixture reduces the loading, increases the coupling impedance, and improves the electronic efficiency

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com