A multiple-frequency ultrasonic cavitation two-phase closed cycle continuous extraction device

A closed-loop, extraction device technology, applied in solid solvent extraction, chemical/physical/physical-chemical processes using energy, etc., can solve the problems of uneven single-frequency ultrasonic sound field, difficulty in feeding and slag discharge, and low extraction rate. , to achieve the effect of rapid and accurate separation, continuous production of equipment and improvement of extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

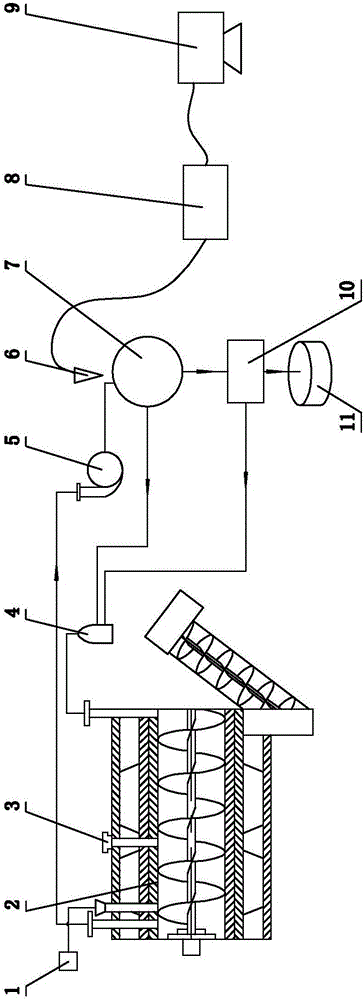

[0028] Depend on figure 1 It can be seen that the multi-frequency ultrasonic cavitation two-phase closed-loop continuous extraction device of this embodiment is composed of an automatic feeder 1, an extraction unit 2, a monitoring unit 3, a modulation unit 4, a return pump 5, an ultrasonic echolocation detector 6, The porous sample collection unit 7, the controller 8, the computer 9, the separator 10, and the sample collector 11 are connected to form.

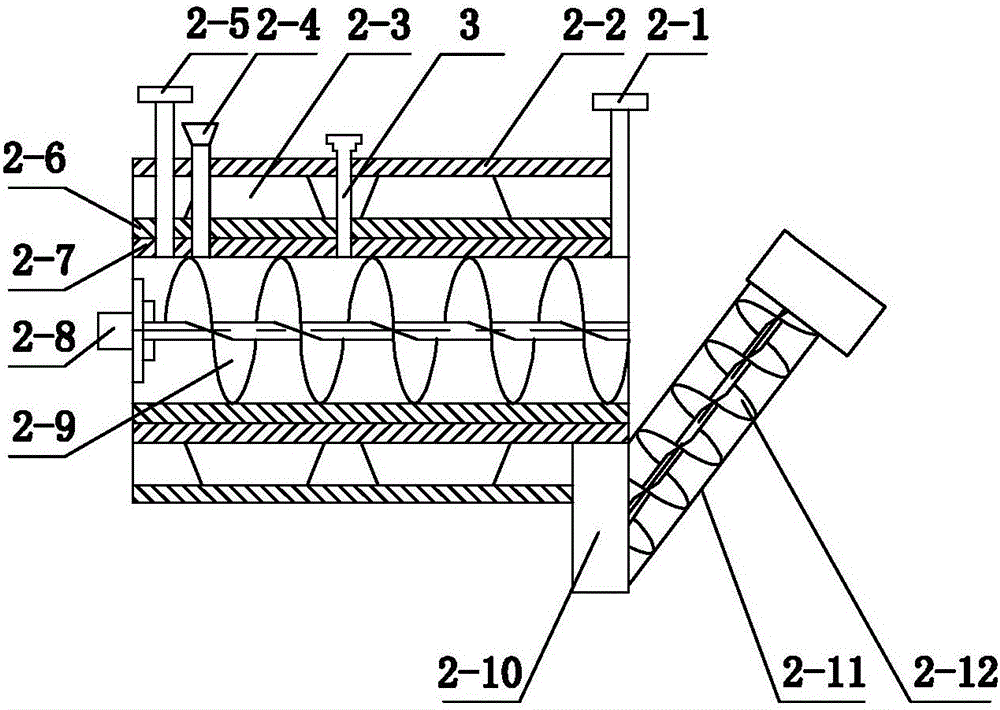

[0029] The extraction unit 2 of this embodiment is composed of an extraction liquid inlet control valve 2-1, a sound-absorbing housing 2-2, an ultrasonic vibrator group 2-3, a feed control valve 2-4, and an extraction liquid outlet control valve 2-5. , cavitation cylinder 2-6, extraction cylinder 2-7, pusher motor 2-8, horizontal screw propeller 2-9, slag discharge motor 2-10, slag discharge pipeline 2-11 and slag discharge screw propeller 2- 12 connection configuration, please refer to figure 2 and 3 .

[0030]A monitorin...

Embodiment 2

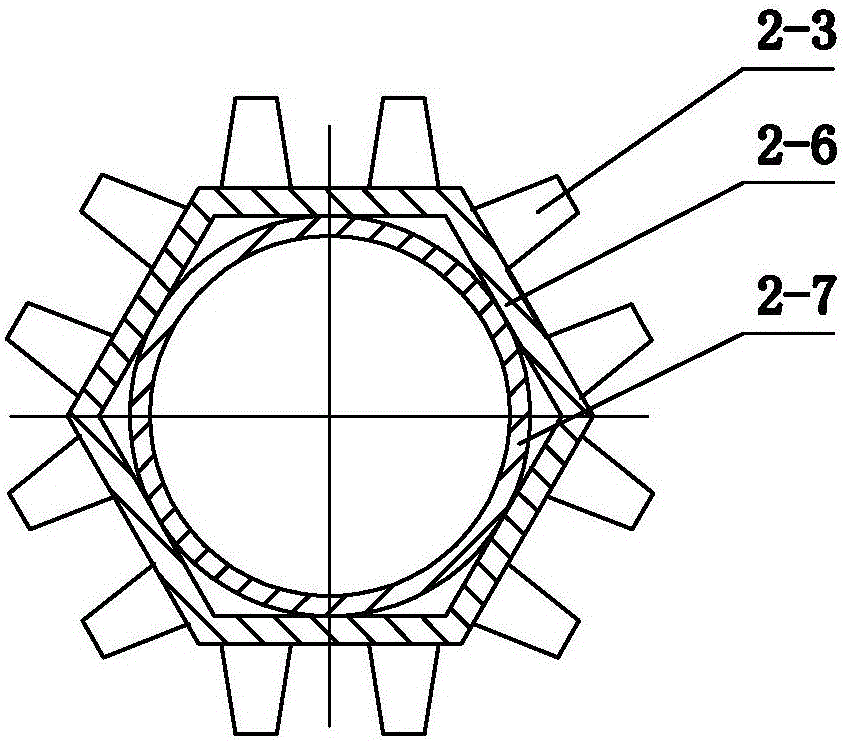

[0039] The cross-section of the cavitation cylinder 2-6 in the extraction unit 2 of this embodiment is an equilateral triangle, and the ultrasonic vibrator groups 2-3 are respectively installed on the three surfaces, wherein the ultrasonic frequency of one ultrasonic vibrator group 2-3 is 20KHz, and the power is 100~ 1500W is continuously adjustable, the ultrasonic frequency of the second ultrasonic vibrator group 2‐3 is 30KHz, and the power is continuously adjustable from 100 to 1500W; the ultrasonic frequency of the third ultrasonic vibrator group 2‐3 is 60KHz, and the power is continuously adjustable from 100 to 1500W , with varying ultrasonic frequencies. Each ultrasonic vibrator group 2-3 is composed of 6 identical ultrasonic vibrator groups 2-3, two by two, arranged in three rows front and back, and distributed on the cavitation cylinder 2-6.

[0040] The porous sample collection unit 7 is provided with 24 sample collection tubes 7-1 on the fixed frame 7-2, with 4 sample...

Embodiment 3

[0044] The cross section of the cavitation cylinder 2-6 in the extraction unit 2 of this embodiment is a regular quadrilateral, and the ultrasonic vibrator groups 2-3 are respectively installed on the four surfaces, and the ultrasonic frequencies of the ultrasonic vibrator groups 2-3 on the two opposite surfaces are the same , that is, the ultrasonic frequency of the ultrasonic vibrator group 2‐3 on the first and third surfaces is 20KHz, and the power is 600W; the ultrasonic frequency of the ultrasonic vibrator group 2‐3 on the second and fourth surfaces is 80KHz, and the power is 400W , each ultrasonic vibrator group 2‐3 is composed of 2 identical ultrasonic vibrator groups 2‐3.

[0045] The porous sample collection unit 7 is provided with 20 sample collection tubes 7-1 on the fixed frame 7-2, with 4 sample collection tubes 7-1 as a cycle, the collection time of each tube is 10min, and every 10min rotates 18 °, other parts are identical with embodiment 1.

[0046] The center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com