Extinguishing agent, engine compartment extinguishing apparatus using it, and engine compartment extinguishing method

A technology for fire extinguishing equipment and engine compartments, applied in fire prevention equipment, fire rescue, etc., can solve problems such as unstable work, low fire extinguishing efficiency, and high cost of use, and achieve the effects of improving occurrence efficiency, improving efficiency, and easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A fire extinguishing agent comprises 55% of an oxidizing agent, 30% of a reducing agent, 8% of an additive, and 7% of a combustion accelerant in a weight-to-component ratio.

[0058] Wherein the oxidizing agent used to produce the airgel includes potassium nitrate, the reducing agent includes phenolic resin, the additive includes magnesium powder silica, and the combustion enhancer includes flammable carbon powder.

Embodiment 2

[0060] A fire extinguishing agent comprises 54% of an oxidizing agent, 28% of a reducing agent, 9% of an additive, and 9% of a combustion accelerant in a composition ratio by weight.

[0061] The oxidant used to produce the airgel is preferably calcium nitrate in this embodiment, the reducing agent is preferably phenolic resin plus dicyandiamide, the additive is preferably aluminum powder and silicon dioxide, and the combustion enhancer includes flammable carbon powder.

Embodiment 3

[0063] A fire extinguishing agent comprises 68% of an oxidizing agent, 25% of a reducing agent, 4% of an additive, and 3% of a combustion accelerant in a composition ratio by weight.

[0064] The oxidant used to produce the aerogel is preferably potassium chlorate in this embodiment, the reducing agent is preferably phenolic resin plus dicyandiamide, the additive is preferably aluminum powder and silicon dioxide, and the combustion enhancer includes flammable carbon powder.

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

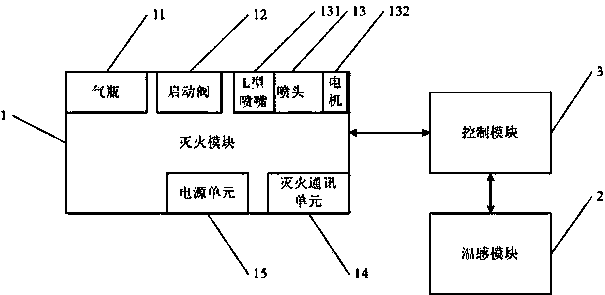

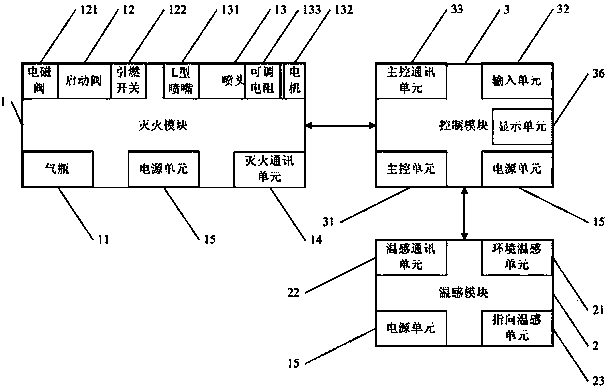

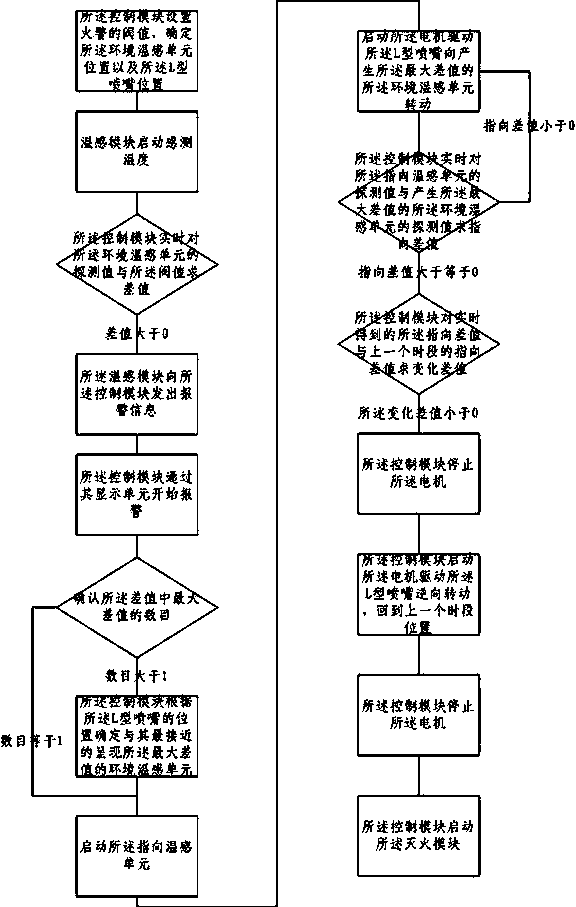

[0066] as attached figure 1 , 2 , 4, a fire extinguishing system for public transportation equipment, mainly includes: a fire extinguishing module 1 for storing fire extinguishing agents and implementing fire extinguishing operations, a temperature sensing module 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap