A rice-wheat combined harvesting and bundling integrated compound working machine

A working machine and compound technology, applied to harvesters, agricultural machinery and implements, agriculture, etc., can solve problems such as unreasonable center of gravity configuration of combine harvesters, low reliability of combine harvesters, and unreasonable power distribution, so as to reduce manpower Effects of input and energy consumption, reduction of straw collection cost, increase of income and rush of farming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

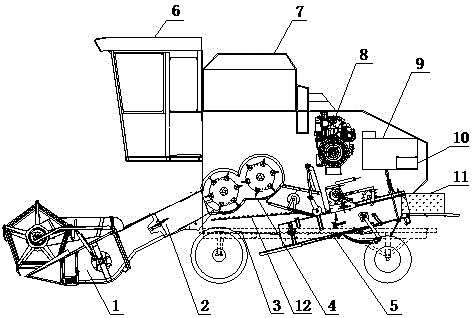

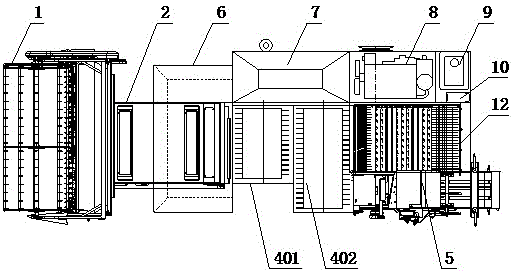

[0038] An integrated compound operation machine for combined harvesting and bundling of rice and wheat, including a material cutting and conveying system, a grain threshing and cleaning system, a straw compression and bundling system, a power system, and auxiliary execution accessories.

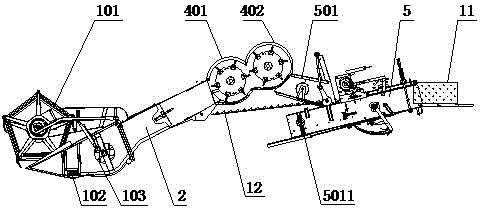

[0039] The material cutting and conveying system includes a material cutting device 1 and a material conveying device 2. The material cutting device 1 is composed of a reeling device 101, a stalk cutting device 102, and a feeding auger device 103. The feeding auger device 103 is located in the material cutting device 1 The tail of the stalk cutting device 102 is located at the front side of the feeding auger device 103, the reeling device 101 is located at the upper side of the stalk cutting device 102, and the reeling device 101 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com