Synthetic resin cap for carbonated beverage-filled container, closure device, and beverage-filled closure device

A technology of carbonated beverages and synthetic resins, applied to bottle/container caps, capping containers with caps, applications, etc., can solve the problems of reduced sealing performance, easy to change, and reduced airtightness of the outer sealing protrusion 44, etc., to prevent Internal deformation, prevention of deterioration of sealing performance, effect of preventing deterioration of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

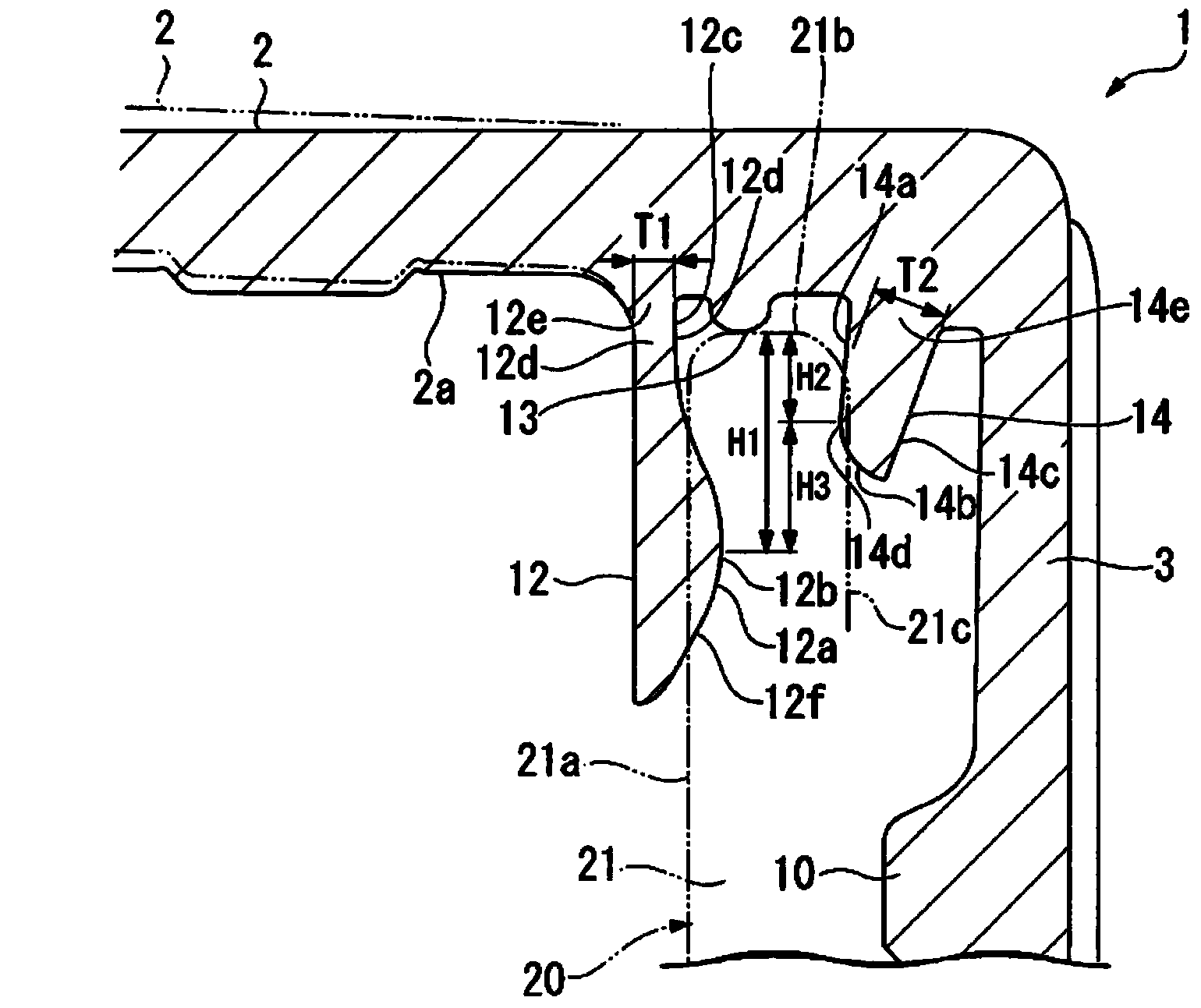

Embodiment 1

[0121] make Figure 1A Cover 1 shown. The cover 1 is made of high-density polyethylene, and no lubricating material is used. The cap 1 was attached to the mouth 21 of the container 20, and the closure was used for a heat cycle test. The ratio (Fo:Fi) of the inward pressing force Fo of the outer sealing protrusion 14 with respect to the outer surface 21c to the outer pressing force Fi of the inner sealing protrusion 12 with respect to the inner surface 21a is 1.5:1.

[0122] In the thermal cycle test, the process of leaving the container 20 and the lid 1 under heating conditions (55° C.) for 9 hours and then under cooling conditions (22° C.) for 15 hours was repeated twice. Then, the container 20 and the lid 1 were placed Cover 1 was left for 24 hours under the condition of 5°C.

[0123] image 3 The results of measuring the outer diameter of the mouth portion 21 of the container 20 before and after the heat cycle test are shown. image 3 The abscissa of is the distance fr...

Embodiment 2

[0130] The curling angle of the same cap 1 as in Example 1 was measured. The number of samples is 25. Figure 5 Indicates the distribution of curling angles. Figure 5 The horizontal axis of is the curling angle, and the vertical axis is the number of samples.

[0131] The curling angle refers to the rotation angle of the cap 1 when the cap 1 is attached to the mouth 21 with a predetermined torque.

[0132] After the cap 1 was manufactured, it was left to stand at room temperature for three days, and then the curling angle was measured at room temperature.

Embodiment 3

[0134] After producing the same cap 1 as in Example 1, it was left to stand at room temperature for three days, then left to stand under heating (55° C.) for 24 hours, and then the curling angle of the cap 1 was measured at room temperature. Other conditions are the same as in Example 2. Figure 5 Indicates the result.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com