A method for testing the compressive strength of concrete using a torque method testing device

A test device and compressive strength technology, applied in the direction of applying stable torsion to test the strength of materials, can solve the problems of damaged steel bars, limited number of core samples, long test period, etc., to achieve easy repair and shorten the test period. , the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

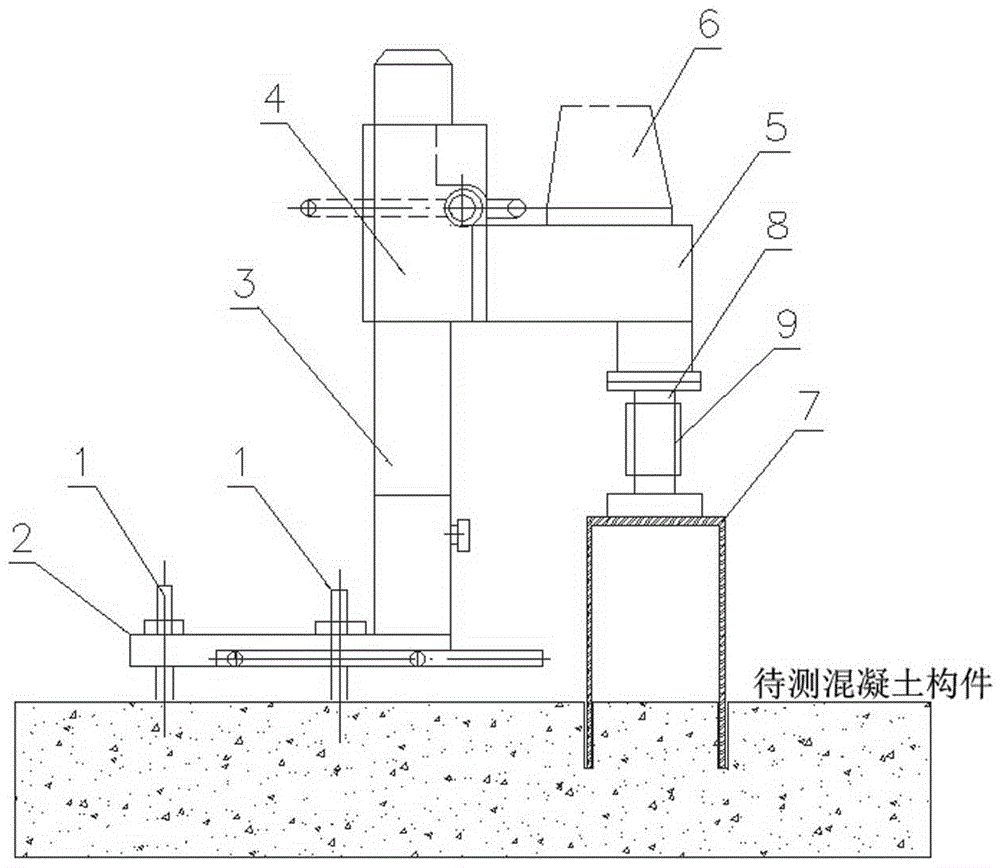

[0015] A method for detecting the compressive strength of concrete using a torque method test device, the torque method test device includes a base 2 fixed on the concrete member to be tested by an expansion bolt 1, and a guide column 3 vertically arranged at one end of the base 2 , the lifting device 4 located on the guide column 3, the lifting device 4 is connected with a crossbeam 5, and the crossbeam 5 is controlled to move up and down, and the end of the crossbeam 5 away from the lifting device 4 is fixed with a motor 6, and the rotating shaft 8 of the motor 6 A hollow drill bit 7 is arranged coaxially at the end of the concrete member to be tested, and a torque sensor 9 is arranged on the rotating shaft 8 . When in use, the motor 6 controls the hollow drill bit 7 to drill a hole at a depth of 3 to 4 centimeters. The hollow drill bit 7 is resisted when it enters the concrete, and torque is generated in the rotating shaft 8 of the motor 6, and the torque value is obtained t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com