Novel heat absorption plate with blue film coating and flat-plate collector with the heat absorption plate

A heat-absorbing plate and coating technology, which is applied in the direction of coating, layered products, heating devices, etc., to achieve the effects of reasonable structure setting, reducing thermal resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

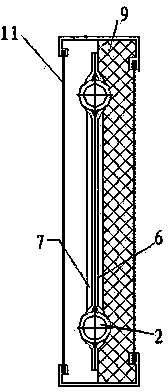

[0026] Preferably, the solar absorption ratio of the blue film coating is above 0.94, and the emissivity is controlled within 0.07.

[0027] Preferably, the material of the metal plate is ultra-pure ferritic stainless steel, of course, stainless steel of other materials can also be selected.

[0028] Specifically, the upper end of the longitudinal connection fluid groove is close to the first transverse fluid groove.

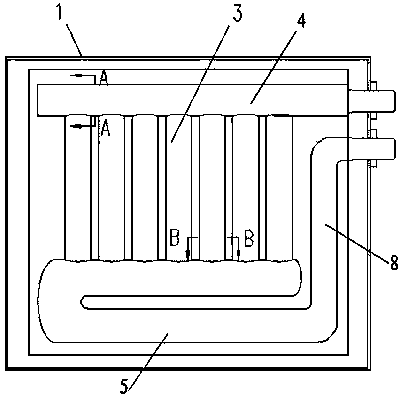

[0029] The arrangement of the U-shaped fluid channel can realize the same course flow of the fluid in the second transverse fluid channel and the fluid in the first transverse fluid channel, that is, the distance that the fluid passes through each longitudinal channel from the inlet to the outlet is equal. This structure can better reduce the resistance in the flow channel, effectively use the flow channel space in the plate core, absorb heat evenly, and maximize the heat collection efficiency.

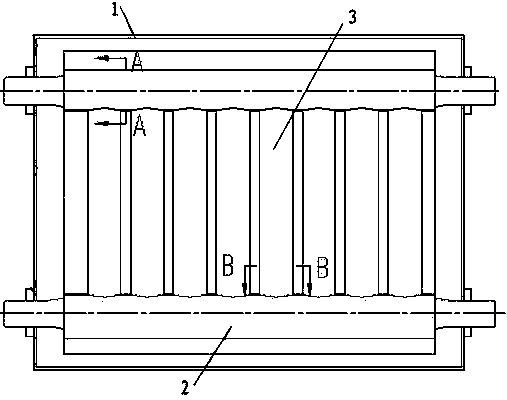

[0030] A flat plate heat collector includes a transparent cover p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com