A control device for a grid-connected low-temperature waste heat power generation system

A control device and power generation system technology, which is applied to steam engine devices, machines/engines, and single-network parallel feeding arrangements, can solve problems such as generator failure, reduced operating efficiency, and deviation from optimal operating speed, and achieve weight reduction, The effect of high stability and safety factor and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

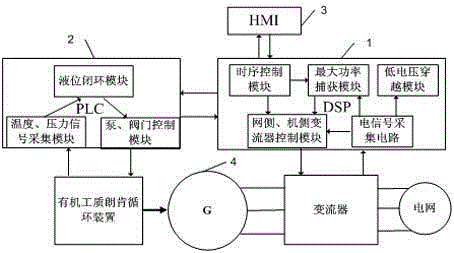

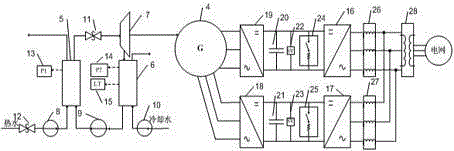

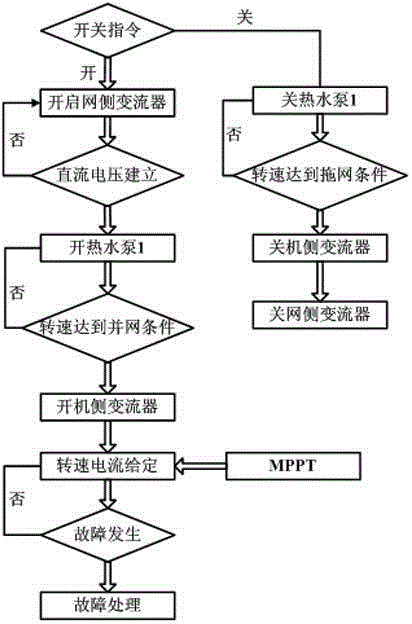

[0027] See attached figure 1 As shown, the grid-connected low-temperature waste heat power generation system consists of a converter control device 1, an organic working medium Rankine cycle control device 2, a human-machine interface 3, a generator 4, an organic working medium Rankine cycle device and a converter. The converter control device 1 is realized by DSP, and the organic working fluid Rankine cycle control device 2 is realized by PLC. The converter control device 1 mainly includes an electrical signal acquisition circuit, a timing control module, a grid-side and machine-side converter control module, a maximum power capture module, and a low voltage ride-through module. The organic working medium Rankine cycle control device 2 mainly includes a temperature and pressure signal acquisition module, a liquid level closed-loop control module, and a pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com