Novel integration house structure

An integrated house and new technology, applied in building components, building structures, walls, etc., can solve the problems of inability to disassemble and assemble at will, labor-intensive, high transportation costs, and achieve good building energy-saving effect, good thermal insulation performance, and mechanical structure. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

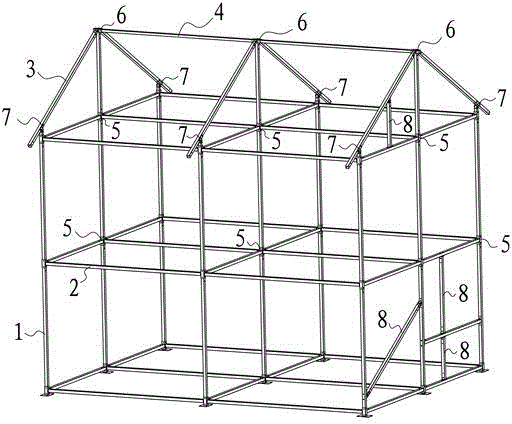

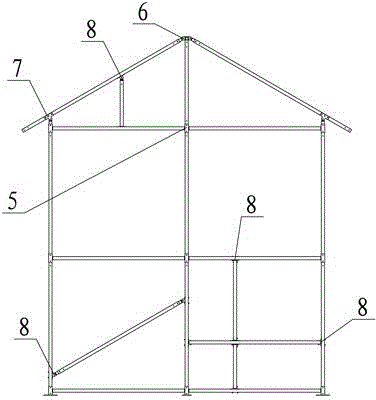

[0029] Depend on Figure 1 to Figure 8 It can be seen that the present invention includes a steel structure frame and a body of wall. The steel structure frame includes vertically connected columns 1 and beams 2, rafters 3 and purlins 4, and the columns 1 and beams 2 are connected and fixed by column and beam connectors 5. The two rafters 3 are connected and fixed by the adjustable purlin connector 6, the column 1 and the rafter 3 are connected and fixed by the adjustable eaves connector 7, and the steel frame structure is supported and reinforced by the support and reinforcement connector 8.

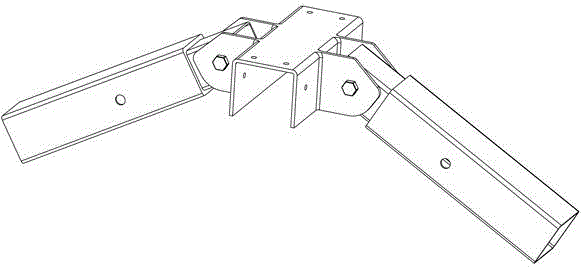

[0030] The post-beam connector 5 of the present invention is composed of an equilateral square column and at least one convex portion welded on the side of the equilateral square column and perpendicular to the extending direction of the equilateral square column.

[0031] The adjustable purlin connector 6 of the present invention is composed of eaves connecting square steel and a base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com