Pile driving limit frame and construction method for offshore wind power foundation pile sinking in intertidal zone

A technology of offshore wind power and limit frame, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as inability to effectively control verticality, extremely high rigidity requirements, and damage to pile holders, so as to ensure uniformity and Scientific, simplify the construction process, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

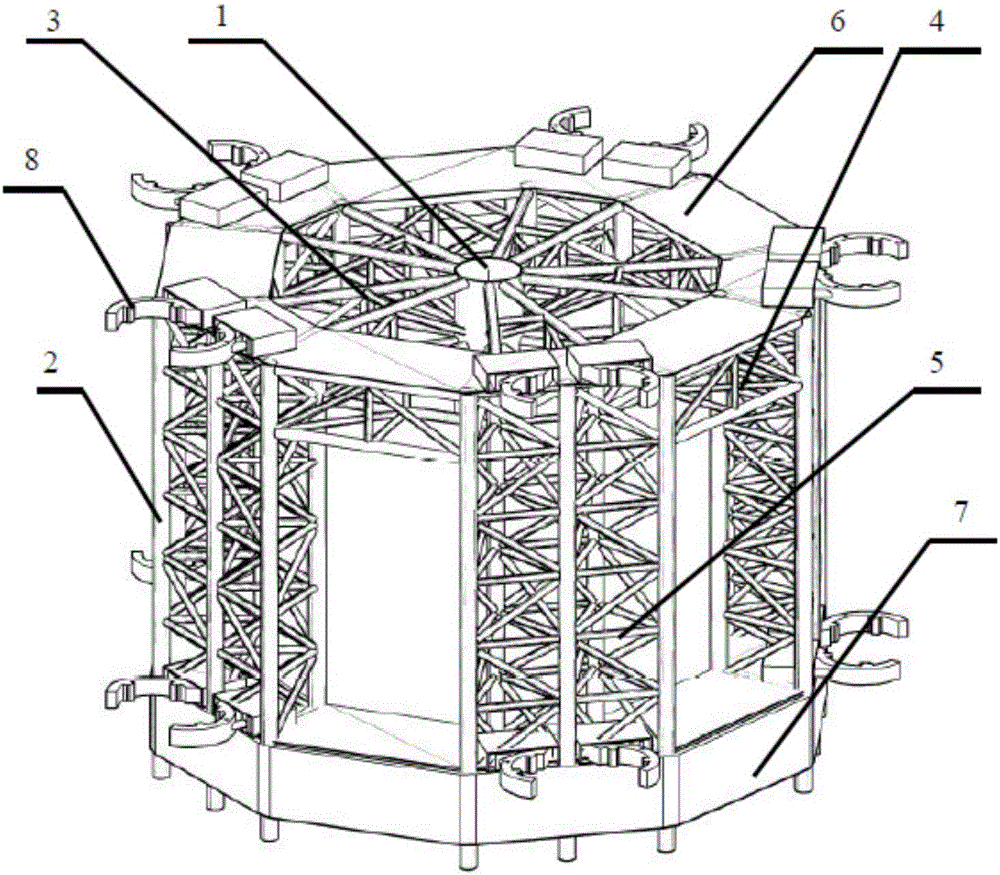

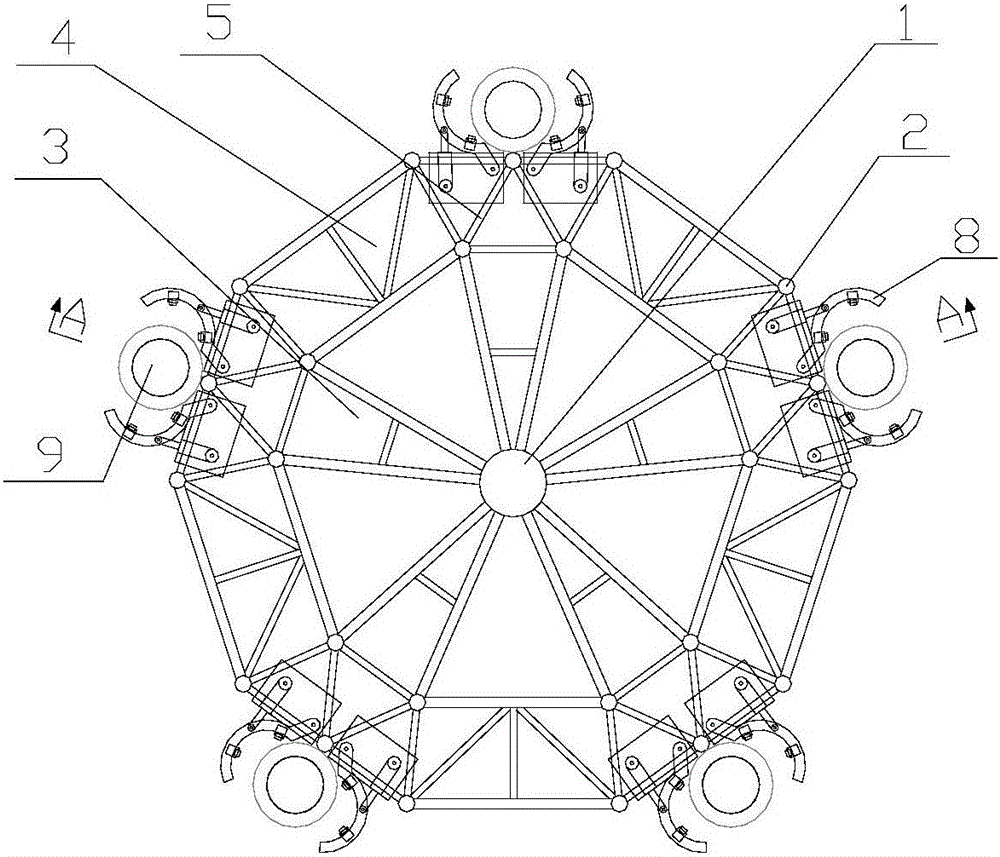

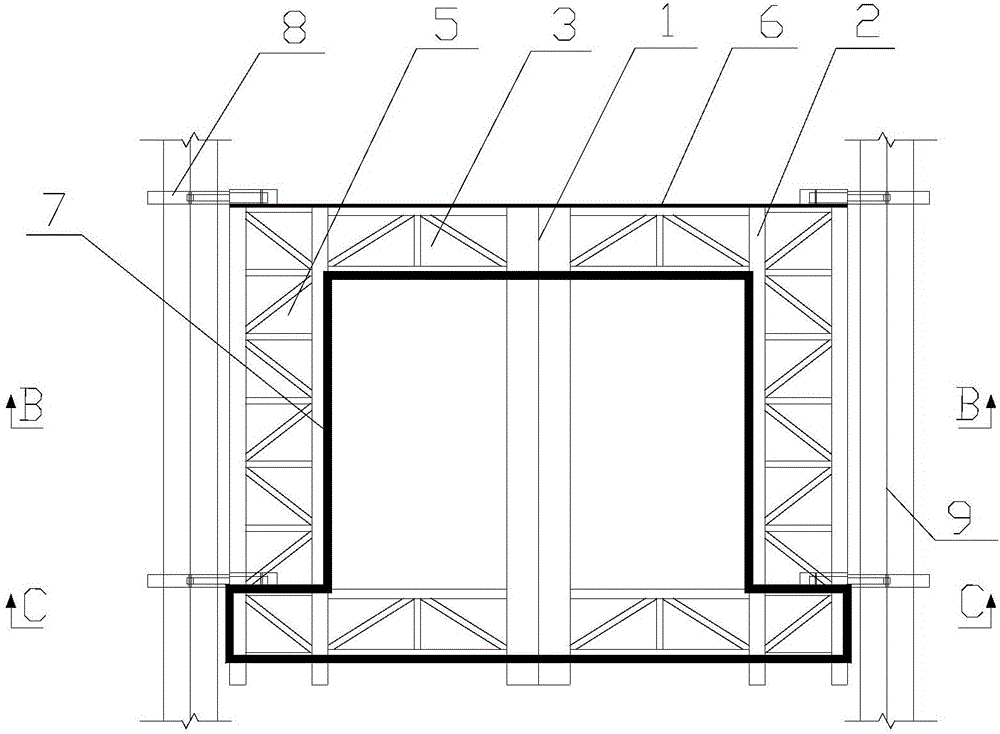

[0033] see attached Figure 1-6, a pile driving limit frame for offshore wind power foundation piles in the intertidal zone, including a central large steel column 1, a truss structure and several water storage tanks 7, and the central large steel column is fixed through the truss structure to form an overall limit frame frame, the truss structure includes a transverse truss 3 connecting the central large steel column and a small steel column, a transverse truss 4 connecting adjacent small steel columns at pile positions, and a longitudinal truss 5 between small steel columns at pile positions. A water container is provided in the position frame structure, and an operation platform 6 is provided on the overall limit frame structure, and a pile holding device 8 is installed on the operation platform and the water container. The cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com