Connecting device for separate hoisting of large offshore platform modules

A technology for offshore platforms and connecting devices, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as unfeasible solutions, lack of floating crane resources, and difficult locking of floating crane resources, and achieve simple structure, The effect of wide applicability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

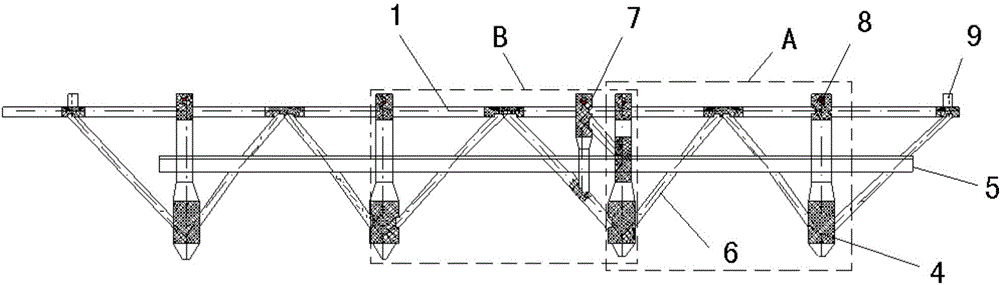

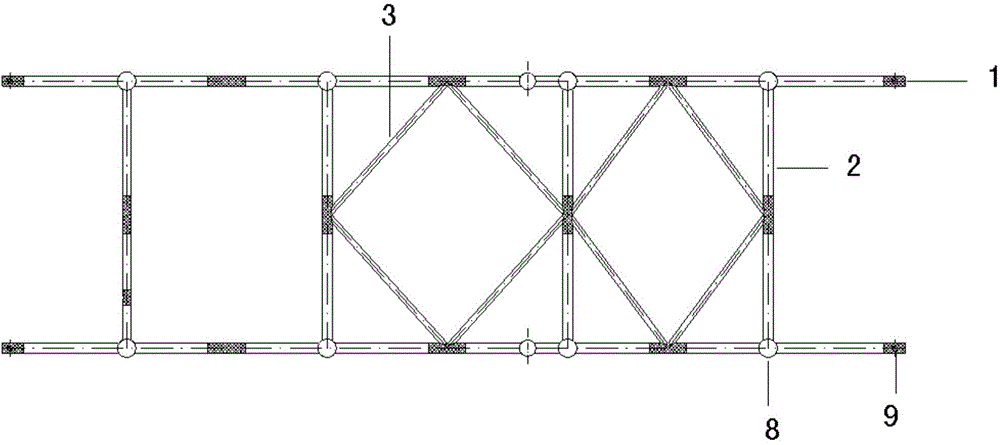

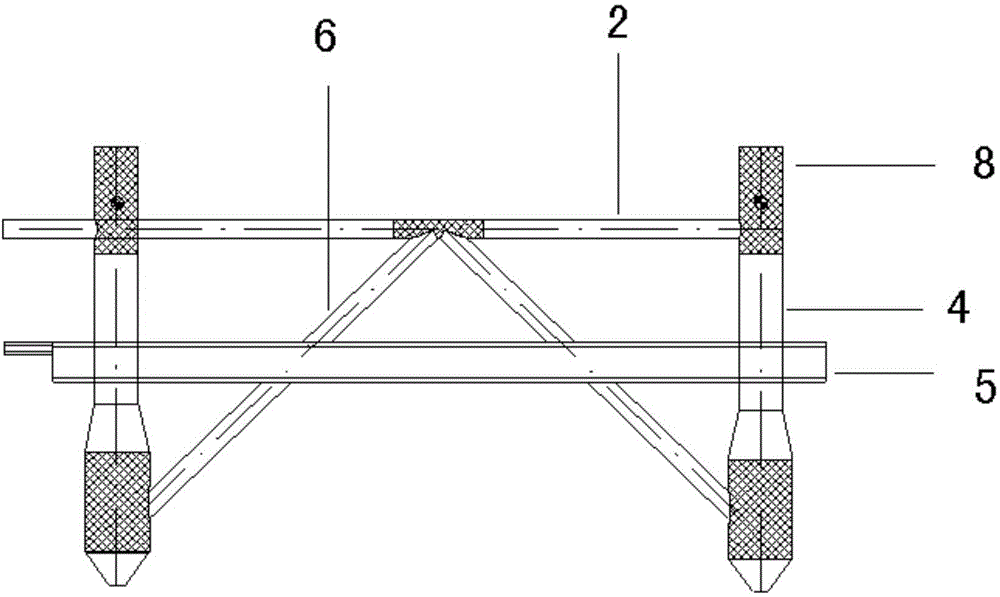

[0022] Such as Figure 1 ~ Figure 4 As shown, the present invention includes two parts, the main support device body and the tip insertion device. The main support connection device body includes a main shaft structural beam 1, a transverse strut 2, a horizontal oblique strut 3, a block main column 4, and a supporting prosthetic leg 7 , working deck 5 and lateral diagonal strut 6. The present invention adopts two oppositely arranged main shaft structural beams 1, and a plurality of transverse struts 2 are fixedly arranged between the two main shaft structural beams 1, and the two adjacent transverse struts 2 are all between the two main shaft structural beams 1 A rectangular frame is formed, and four horizontal diagonal struts 3 connected end to end are fixedly arranged in each rectangular frame, and each horizontal diagonal strut 3 is fixedly dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com