Method for preparing flue gas by using high-temperature cracking biomass

A high-temperature pyrolysis and biomass technology, which is applied in the manufacture of combustible gas, fixed bed gasification, petroleum industry, etc. The effect of gas production and increasing effective gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

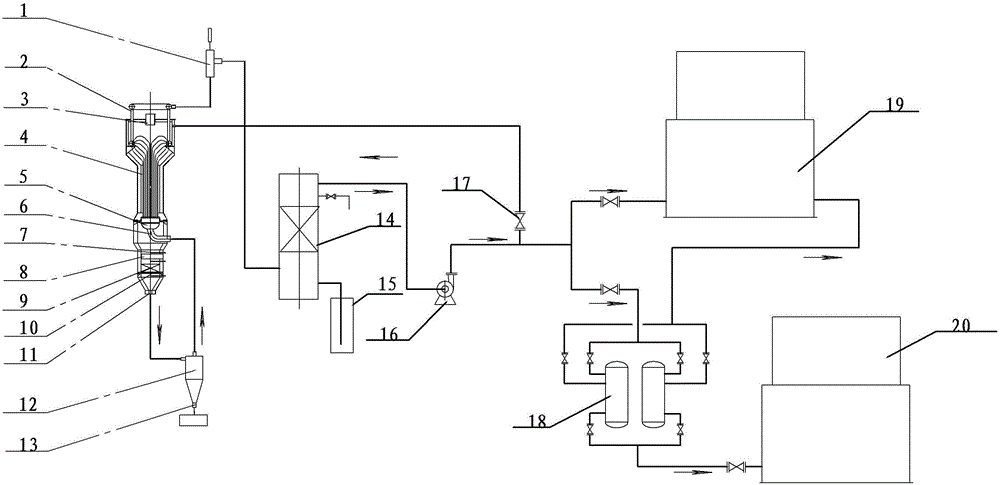

[0017] Below according to accompanying drawing and specific embodiment the gas making process of the present invention is described in detail as follows:

[0018] The raw materials are fed continuously or intermittently from the furnace feeding port 3, and the raw materials added to the furnace are dried and cracked from top to bottom due to the high-temperature gas in the tubes 4 of the heat exchanger in the furnace, and the cracked gas and raw materials are generated. Substances charcoal, biomass oil and tar. The generated cracked gas carries biochar, biomass oil and tar into the lower tar cracking section, where the cracked gas, biomass charcoal, biomass oil and tar are heated to above 800°C by the heating device 8, and the tar cracking has been achieved. The tar and biomass oil in the high-temperature gas of high temperature are catalytically cracked by the cracking catalyst 9 placed on the grate 10, and 99.5% of the biomass oil and tar in the cracked gas are cracked into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com