Preparation method for group I-III-VI tri-element semiconductor nanocrystalline light-emitting film

A light-emitting thin film and semiconductor technology, which is applied in the direction of semiconductor devices, light-emitting materials, chemical instruments and methods, etc., can solve the problems of particle agglomeration, volatilization, and increased difficulty, and achieve a wide coverage of fluorescence spectrum, simple synthesis equipment, and synthesis temperature mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

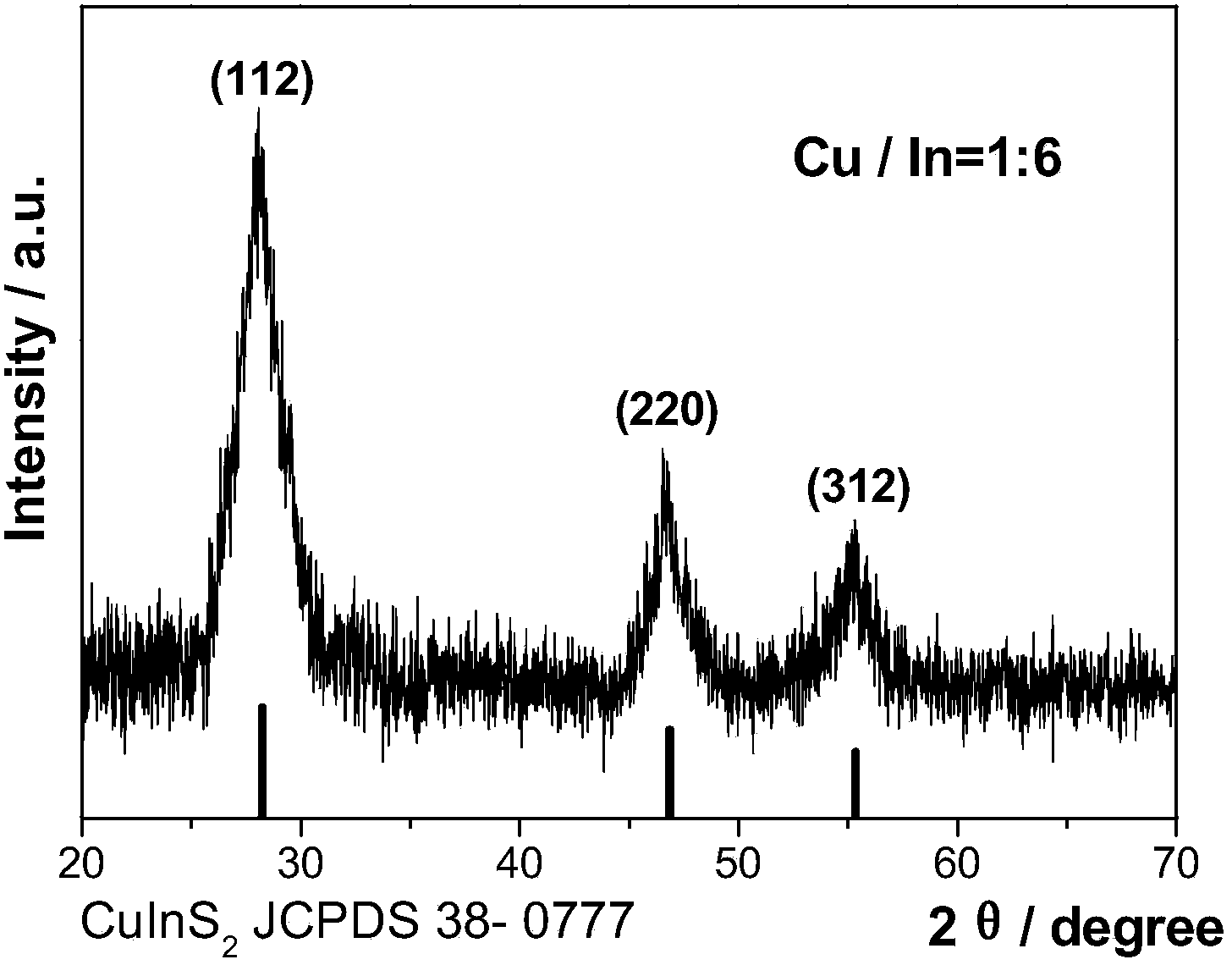

[0030] Example 1CuInS 2 Preparation method of ternary semiconductor nanocrystal luminescent film

[0031] In the first step, 9.9mg (0.1mmol) CuCl, 29.35mg (0.1mmol) InCl 3 4H 2 0, 2mmol n-dodecyl mercaptan, 0.2mmol oleic acid were added in the 8mL octadecene three-necked flask to obtain the mixed precursor solution; feed argon to get rid of the air, under the conditions of magnetic stirring and argon protection, Heat and mix the precursor solution to 180°C, under stirring, make CuCl, InCl 3 Dissolve completely until a pale yellow clear solution is formed.

[0032] In the second step, quickly inject 4 mL of sulfur in oleylamine solution into the light yellow clear solution (dissolve sulfur powder in oleylamine to make the sulfur concentration 0.2 mol / L). Adjust the temperature to 160°C, maintain the temperature, and let the reaction proceed for 90 minutes to prepare CuInS 2 Ternary semiconductor nanocrystal solution.

[0033] The third step, remove the heat source, make C...

Embodiment 2A

[0037] Example 2AgInS 2 Preparation method of ternary semiconductor nanocrystal luminescent film

[0038] In the first step, 16.9mg (0.1mmol) AgNO 3 , 29.35 mg (0.1 mmol) InCl 3 4H 2 0, 3mmol n-dodecyl mercaptan, 0.6mmol oleic acid were added in the 8mL octadecene three-necked flask, to obtain the mixed precursor solution; feed argon to get rid of the air, under the conditions of magnetic stirring and argon protection, Heat the mixed solution to 90°C and, under stirring, make the AgNO 3 , InCl 3 Dissolve completely until a pale yellow clear solution is formed.

[0039] In the second step, quickly inject 4mL sulfur oleylamine solution into the light yellow clear solution (dissolve sulfur powder in oleylamine to make the sulfur concentration 0.2mol / L), adjust the temperature to 110°C, and maintain the temperature, The reaction was carried out for 90min to prepare AgInS 2 Ternary semiconductor nanocrystal solution.

[0040] The third step, remove the heat source, make AgI...

Embodiment 3A

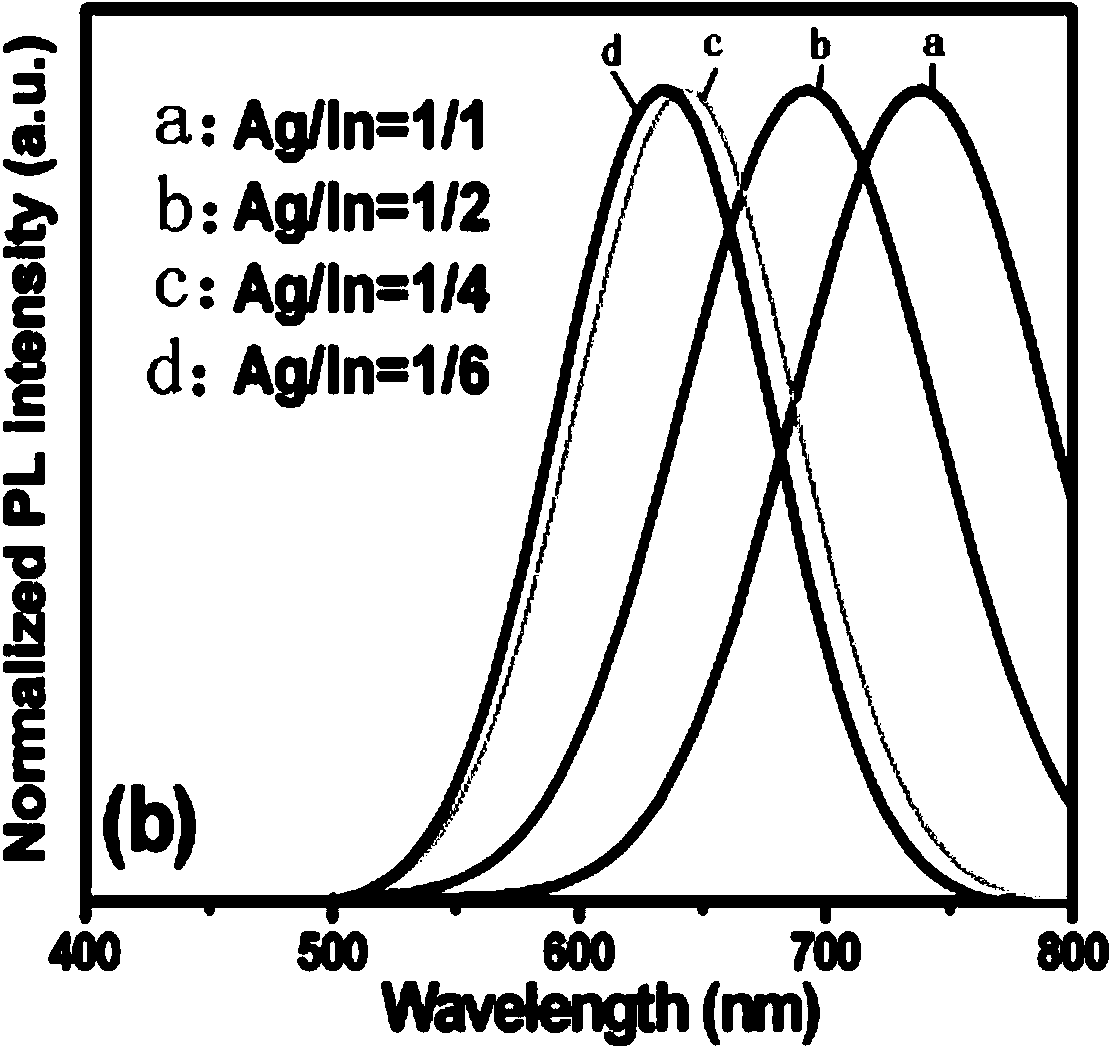

[0044] Example 3AgInS 2 Preparation method of ternary semiconductor nanocrystal luminescent film

[0045] In the first step, 16.9mg (0.1mmol) AgNO 3 , 58.7 mg (0.2 mmol) InCl 3 4H 2 0, 3mmol n-dodecyl mercaptan, 0.6mmol oleic acid were added in the 8mL octadecene three-necked flask, to obtain the mixed precursor solution; feed argon to get rid of the air, under the conditions of magnetic stirring and argon protection, Heat the mixed solution to 90°C and, under stirring, make the AgNO 3 , InCl 3 Dissolve completely until a pale yellow clear solution is formed.

[0046] In the second step, quickly inject 4mL sulfur oleylamine solution into the light yellow clear solution (dissolve sulfur powder in oleylamine to make the sulfur concentration 0.2mol / L), adjust the temperature to 110°C, and maintain the temperature, The reaction was carried out for 90min to prepare AgInS 2 Ternary semiconductor nanocrystal solution.

[0047] The third step, remove the heat source, make AgIn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com