A composition for 3D printing, its preparation and use method, and its products

A technology of 3D printing and composition, applied in the field of 3D printing composition, can solve the problems of 3D printing practicability, limitation of universality, poor performance of finished product strength and toughness, slow molding speed, etc., so as to avoid chemical changes , Improve mechanical strength and reduce brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

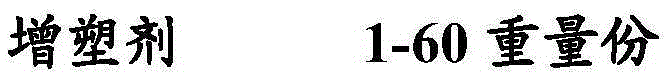

[0071] A composition for 3D printing, in which the components except the solvent are recorded in parts by weight as:

[0072]

[0073] The above composition is gradually added to 100 parts of dichloromethane under the conditions of nitrogen protection and 300 rpm stirring speed. After the addition is completed, stirring is continued for 20 minutes, and then sealed and stored in the dark. It can still be used after being placed for more than 12 months.

Embodiment 2

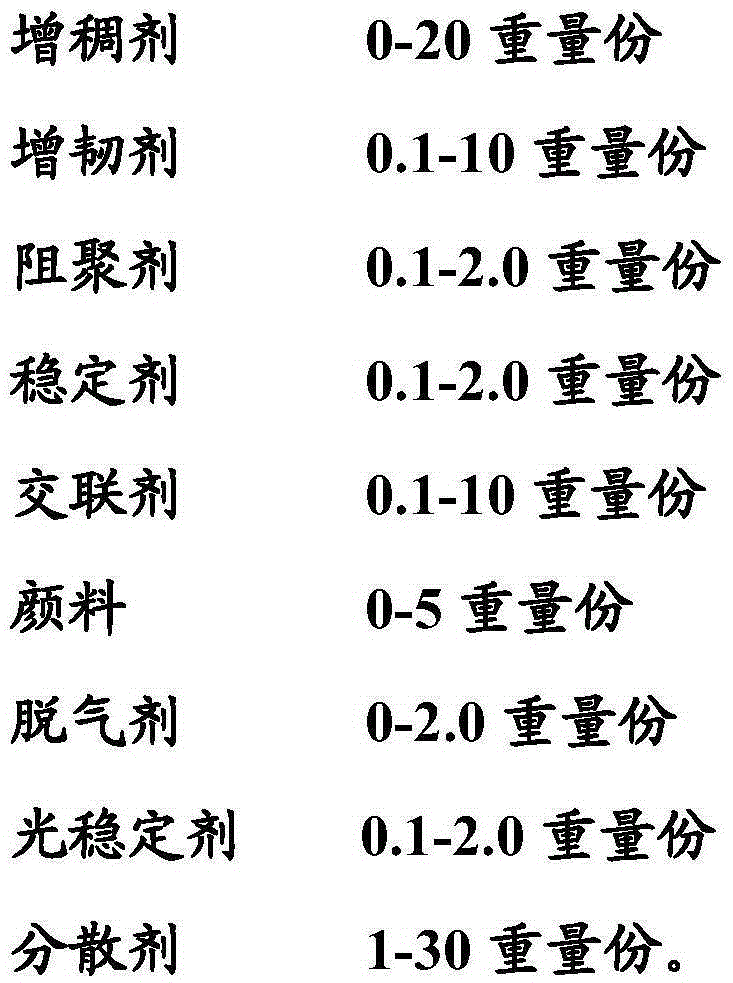

[0075] A composition for 3D printing, in which the components except the solvent are recorded in parts by weight as:

[0076]

[0077]

[0078] The components of the above composition are gradually added to 100 parts of dichloromethane under the conditions of nitrogen protection and 300rpm stirring speed. After the addition is completed, continue to stir for 30 minutes, and then seal and store in the dark to obtain a pink color for 3D printing. combination.

[0079] The above-mentioned materials are combined with other yellow, blue, and black materials, and the temperature of the printing cavity is controlled to 50°C and the relative humidity is 45% to obtain colorful 3D printed products.

Embodiment 3

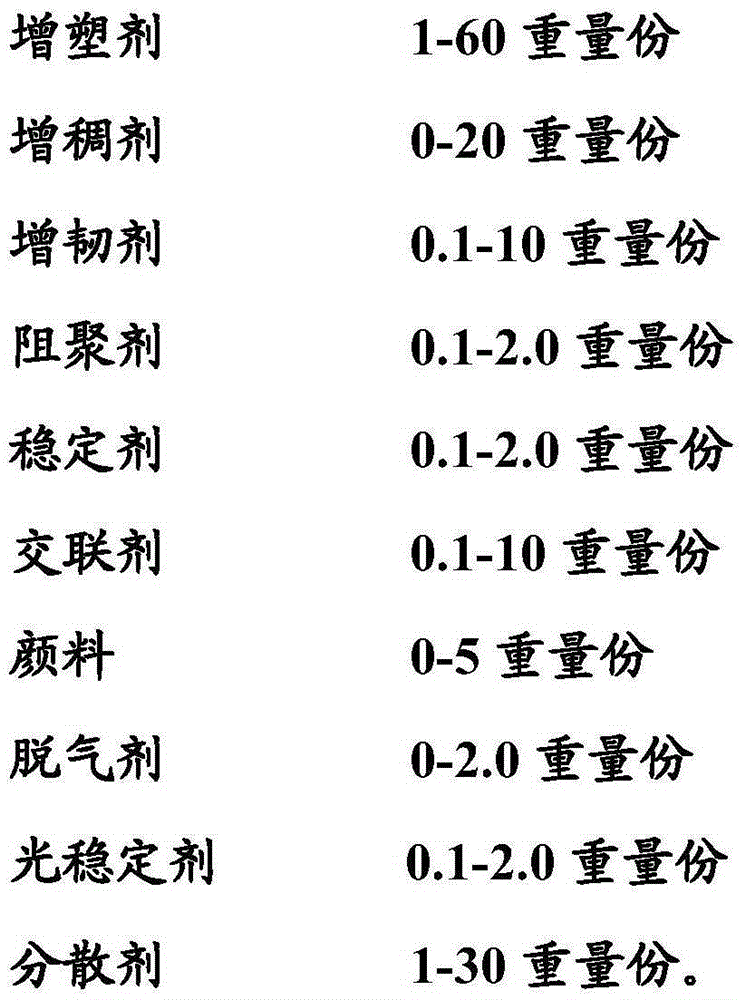

[0081] A composition for 3D printing, in which the components except the solvent are recorded in parts by weight as:

[0082]

[0083] The components of the above composition are gradually added to 120 parts of dioxane under nitrogen protection and a stirring speed of 300 rpm. After the addition is completed, stirring is continued for 30 minutes, and then sealed and stored in the dark.

[0084] Using the Z402 printer of ZCorporation Company (need to add humidity control components, control the temperature of the printing chamber at 30°C, and the relative humidity at 45%), the above-mentioned composite materials can print polymer products with high mechanical strength and conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com