Acylated chitin fiber and preparation method thereof, and application of acylated chitin fiber in preparation of surgical suture

A technology of chitin fiber and acylation, applied to acylated chitin fiber and its preparation, and its application in the preparation of surgical sutures. In the field of chitin fibers, it can solve the problem of low wet strength, low joint strength, and easy breakage of surgical threads. problems, to achieve the effect of high mechanical strength, wide application and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

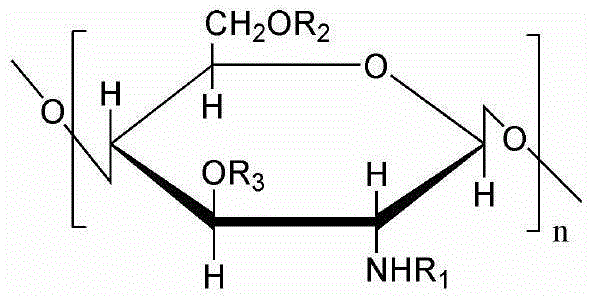

[0018] A kind of acylated chitin fiber is composed of acylated chitin, and its molecular structure formula is:

[0019]

[0020] In the formula, R 1 , R 2 or R 3 is H, acetyl (-C 2 h 3 O), propionyl (-C 3 h 5 O) or butyryl (-C 4 h 7 One or more of (2), n is greater than 100, and according to the technical common sense of those skilled in the art, the n value can be larger under the possibility that the technology can be realized, because the performance of the fiber corresponding to the larger n value is more excellent. The number of acyl groups per sugar unit of acylated chitin is greater than 1, that is, the degree of acylation of acylated chitin is greater than 100%, and the average number of acyl groups in every 100 sugar units is greater than 100; the acyl groups are acetyl, propylene One or more of acyl or butyryl, the acylation degree is the sum of one or more acylation degrees of acetyl, propionyl or butyryl in the acylated chitin. Therefore, the degree of ...

Embodiment 2

[0023] The preparation method of the acylated chitin fiber is as follows: take 50 g of commercially available chitin fiber, fix the fiber on a plastic stirring support, keep the fiber orderly, and set it aside for later use. Add 30mL of the acylating reagent acetic anhydride solution into the glass reaction vessel (the molar ratio of chitin fiber to acetic anhydride is 1:1.26), and add a 70% perchloric acid solution by weight according to 5% of the volume of the acetic anhydride solution 1.5ml was used as a catalyst, and 220ml of methanol was added to make the solid-to-liquid ratio (w / v) of the reaction system 1:5, and stirred evenly. Then put the chitin fiber and the bracket into the above glass reaction vessel, close the reaction vessel, control the reaction temperature to 10° C., and stir for 24 hours. After the reaction is complete, take out the fiber, remove the excess reaction solution, put the fiber into a 10% NaOH alkaline aqueous solution by weight, neutralize the aci...

Embodiment 3

[0025] The preparation method of the acylated chitin fiber is as follows: weigh 50 g of the chitin fiber, fix the fiber on a plastic stirring support, and set aside. Add 80 mL of acylating reagent butyric anhydride solution (the molar ratio of chitin fiber to butyric anhydride is 1:2.06) in the glass reaction vessel, add 2 ml of sulfuric acid solution with a concentration of 70% by weight according to 2.5% of the volume of butyric anhydride solution as Catalyst, add 220ml of ethanol to make the solid-to-liquid ratio (w / v) of the reaction system 1:6, and stir evenly. Then put the chitin fiber and the bracket into the above glass reaction vessel, close the reaction vessel, control the reaction temperature to 0° C., and stir for 72 hours. After the reaction is complete, take out the fiber, remove the excess reaction solution, put the fiber into an alkaline aqueous solution of NaOH with a concentration of 20% by weight, neutralize the acid and alkali, take out the fiber, wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com