Method for preparing single-domain yttrium barium copper oxide bulk superconductor by taking Y2BaCuO5 as base material

A technology of yttrium barium copper oxide and matrix materials, which is applied in the field of high-temperature copper oxide superconducting materials, can solve the problems of changing the initial ratio of the liquid phase source block, unfavorable growth and performance of the sample block, and waste of the liquid phase, etc., to improve Stability and repeatability, shortening the experimental cycle, avoiding the effect of tilting or collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

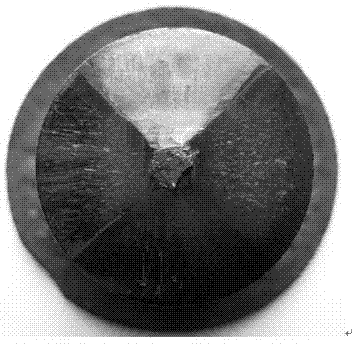

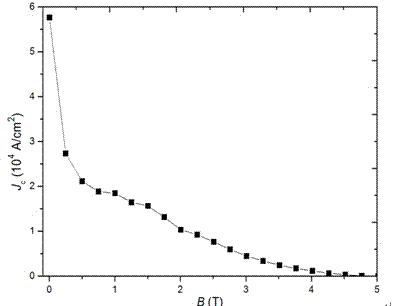

Examples

Embodiment 1

[0025] (1) Prepare Y 2 BaCuO 5 Precursor powder:

[0026] Take 73.8453g Y 2 o 3 , 50.1414g BaO, 26.0133g CuO initial powder mixed evenly, namely Y 2 o 3 The molar ratio of BaO and CuO initial powder is 1:1:1, and Y is made by solid state reaction method 2 BaCuO 5 precursor powder;

[0027] (2) Preparation of liquid phase source powder:

[0028] Take 80.4435g BaO and 69.5565g CuO primary powder and mix evenly, that is, the molar ratio of BaO and CuO primary powder is 3:5, and the nominal composition is Ba 3 Cu 5 o 8 mixed powder; then take 100g Ba 3 Cu 5 o 8 Mix powder with 15g Y 2 BaCuO5 Mix the precursor powder evenly, that is Ba 3 Cu 5 o 8 Mix powder with Y 2 BaCuO 5 The mass ratio of the precursor powder is 1:0.15, which is used as the liquid phase source powder;

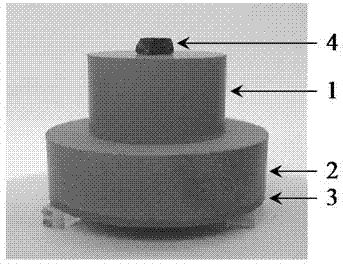

[0029] (3) Press the precursor block:

[0030] Take 12g Y 2 BaCuO 5 Put the precursor powder into a cylindrical mold 1 (20 mm in diameter) and press it into Y 2 BaCuO 5 Solid-phase block;...

Embodiment 2

[0040] In step (2) of preparing the liquid phase source powder, prepare Ba 3 Cu 5 o 8 The raw material that mixed powder is used and preparation method are identical with embodiment 1, get 100g Ba again 3 Cu 5 o 8 Mix powder with 10g Y 2 BaCuO 5 Mix the precursor powder evenly, that is Ba 3 Cu 5 o 8 Mix powder with Y 2 BaCuO 5 The mass ratio of the precursor powder is 1:0.1, which is used as the liquid phase source powder.

[0041] In step (3) of pressing the precursor block, take 6g of Y 2 BaCuO 5 The precursor powder is put into a cylindrical mold 1 (diameter 16 mm) and pressed into Y 2 BaCuO 5 Solid phase block; take 7.5g of liquid phase source powder and put it into a cylindrical mold 2 (20 mm in diameter) and press it into a liquid phase source block; that is, the Y 2 BaCuO 5 The mass ratio of the precursor powder to the liquid phase source powder is 1:1.25, and the diameter of the cylindrical mold 2 is 4 mm larger than that of the cylindrical mold 1; 2 B...

Embodiment 3

[0045] In step (2) of preparing the liquid phase source powder, prepare Ba 3 Cu 5 o 8 The raw material that mixed powder is used and preparation method are identical with embodiment 1, get 100g Ba again 3 Cu 5 o 8 Mix powder with 20g Y 2 BaCuO 5 Mix the precursor powder evenly, that is Ba 3 Cu 5 o 8 Mix powder with Y 2 BaCuO 5 The mass ratio of the precursor powder is 1:0.2, which is used as the liquid phase source powder.

[0046] In step (3) of pressing the precursor block, take 6g of Y 2 BaCuO 5 The precursor powder is put into a cylindrical mold 1 (diameter 16 mm) and pressed into Y 2 BaCuO 5 Solid phase block; take 10.5g of liquid phase source powder and put it into a cylindrical mold 2 (30 mm in diameter) and press it into a liquid phase source block; that is, the Y 2 BaCuO 5 The mass ratio of the precursor powder to the liquid phase source powder is 1:1.75, and the diameter of the cylindrical mold 2 is 14 mm larger than that of the cylindrical mold 1; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com