Method for preparing concrete with dry-process detoxified chromium slag as concrete mineral additive

A mineral admixture and concrete technology, applied in the field of building materials, can solve problems such as polluting the environment and occupying cultivated land, and achieve the effects of solving environmental problems, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

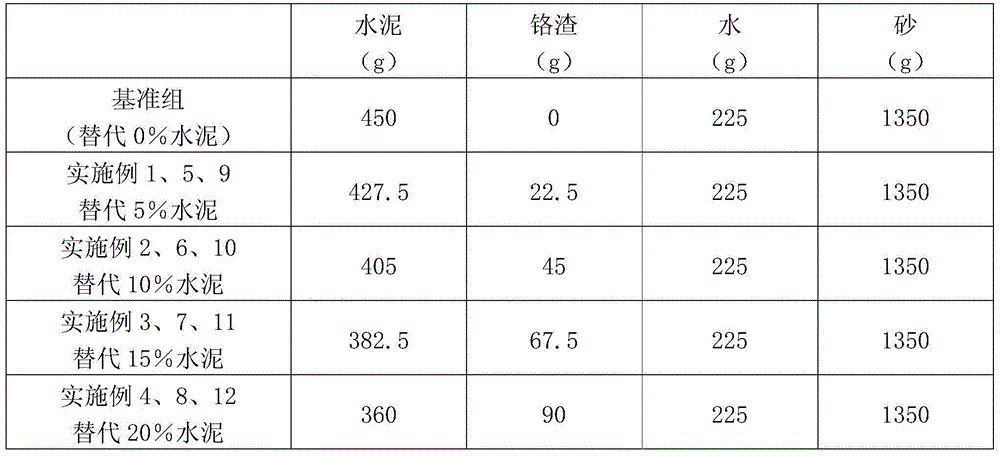

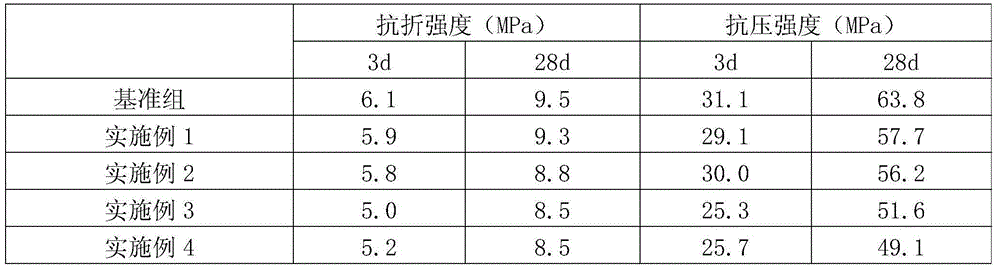

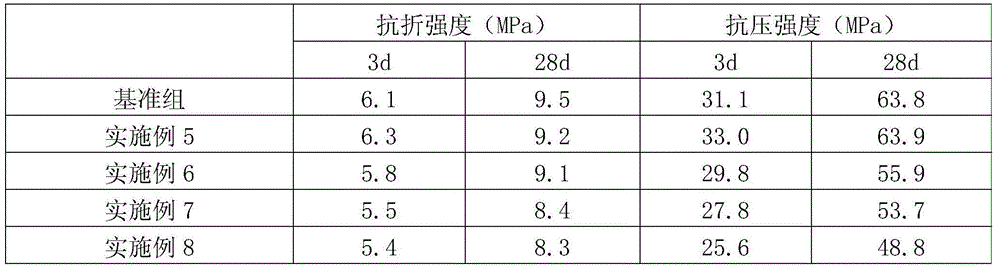

[0025] Example 1-12, Preparation of cement mortar material and performance testing of dry method detoxification chromium slag partially replacing cement

[0026] Cement mortar is a kind of generalized concrete, which is fine aggregate concrete. This group of experiments uses cement mortar to determine the use and dosage of dry detoxification chromium slag.

[0027] The experiment includes the following specific steps:

[0028] 1) Grind the dry detoxification chromium residue until the specific surface area is 600m 2 / kg (embodiment 1-4, measured value is 606m 2 / kg), 450m 2 / kg (embodiment 5-8, measured value is 468m 2 / kg), 300m 2 / kg (embodiment 9-12, measured value is 289m 2 / kg). Here, the detoxified chromium slag fine powder is obtained by grinding, and the allowable value of the measured specific surface area is (expected value ± 20) m 2 / kg.

[0029] 2) use dry detoxification of 0%, 5%, 10%, 15%, 20% (by mass) accounting for the total amount of cementitious mat...

Embodiment 13-15

[0046] Example 13-15, Preparation of Concrete Material and Its Performance Testing Using Dry Process Detoxification Chromium Slag Partially Substituting Concrete Mineral Admixtures

[0047] In engineering concrete materials, concrete mineral admixtures such as slag powder and fly ash are usually used to improve the mechanical properties and durability of concrete. In this group of examples, the detoxified chromium slag is used to partially replace the common mineral admixture (taking fly ash as an example) to illustrate the application of the detoxified chromium slag in concrete materials.

[0048] Include the following steps:

[0049] 1) Grind dry detoxification chromium residue until the specific surface area is 468m 2 / kg (this example is represented by this data, 300-600m 2 / kg can be);

[0050] 2) Replace the mineral admixture fly ash in the concrete batching with dry method detoxification chromium slag, the dosage is cementitious material (the total amount of cement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com