System and method for purifying and recycling amine liquid of smoke CO2 trapping system for coal-fired power plant

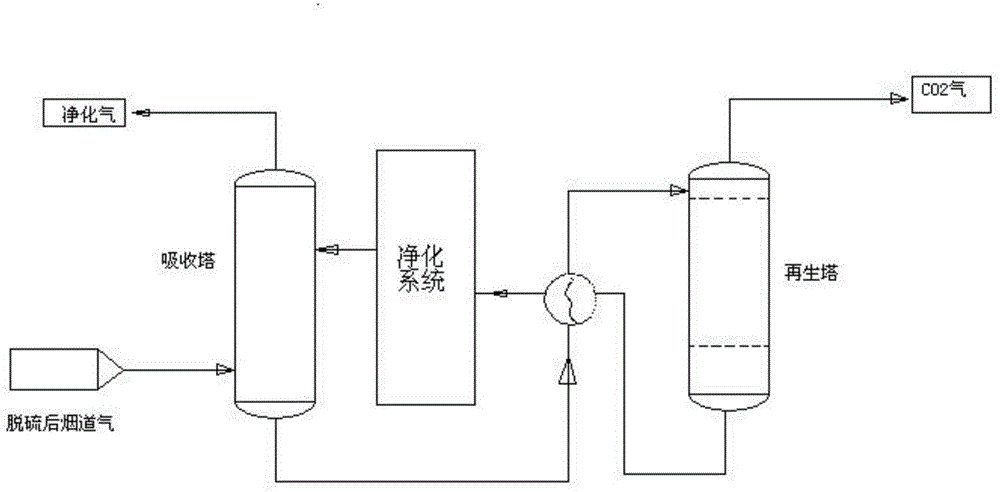

A coal-fired power station, amine solution technology, applied in chemical instruments and methods, separation methods, water/sewage multi-stage treatment, etc., can solve the problems of easy oxidation and degradation of alcohol amine solution, strong corrosion of equipment, complicated operation, etc. , to achieve good regeneration effect, ensure safe operation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

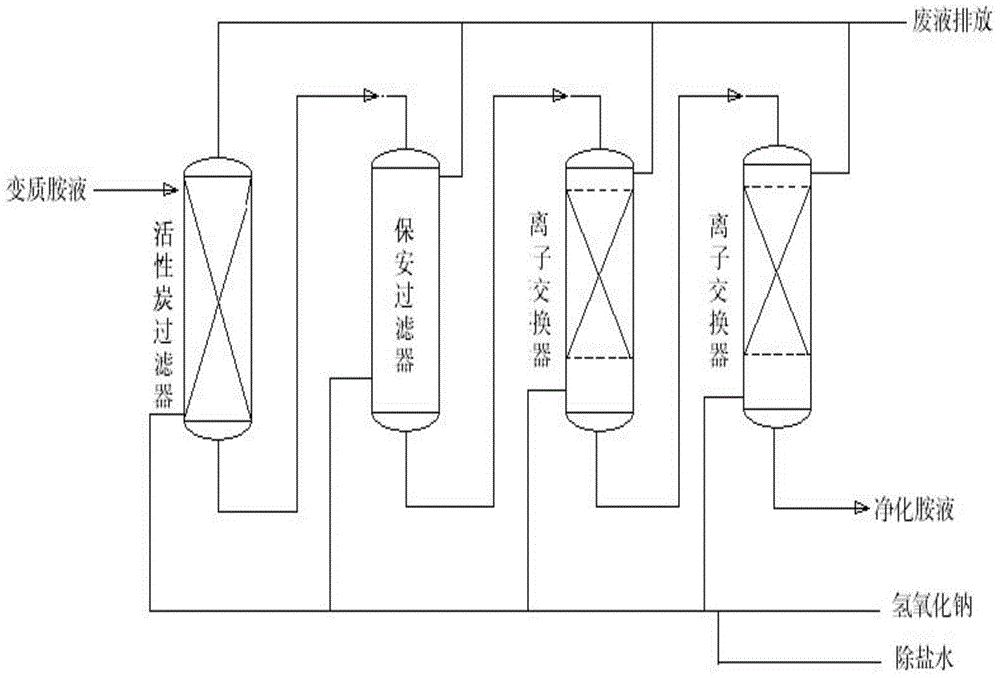

[0044] Coal-fired power plant flue gas CO of the present invention 2 The purification and reuse method of amine liquid in the trapping system adopts filtration to remove impurities and macroporous adsorption-strong alkali mixed anion exchange resin to purify the organic amine solution.

[0045] Organic amine solution purification principle:

[0046] The deteriorated amine liquid first enters the activated carbon filter and security filter for removing suspended solids to remove impurities such as hydrocarbons in the amine liquid, and the pretreated amine liquid continues to enter the ion exchanger for removing heat-stable salts to remove the amine liquid The heat-stable salt in the tank, the purified amine liquid returns to the capture system.

[0047] Such as figure 1 Shown, the present invention a kind of coal-fired power plant flue gas CO 2 The amine liquid purification and reuse system of the capture system includes a connected activated carbon filter and a security fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com