Automatic carton nailing machine

A carton stapler and carton technology, which is applied in the field of automatic carton processing devices, can solve the problems of low production efficiency, large errors, affecting the appearance of carton boxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

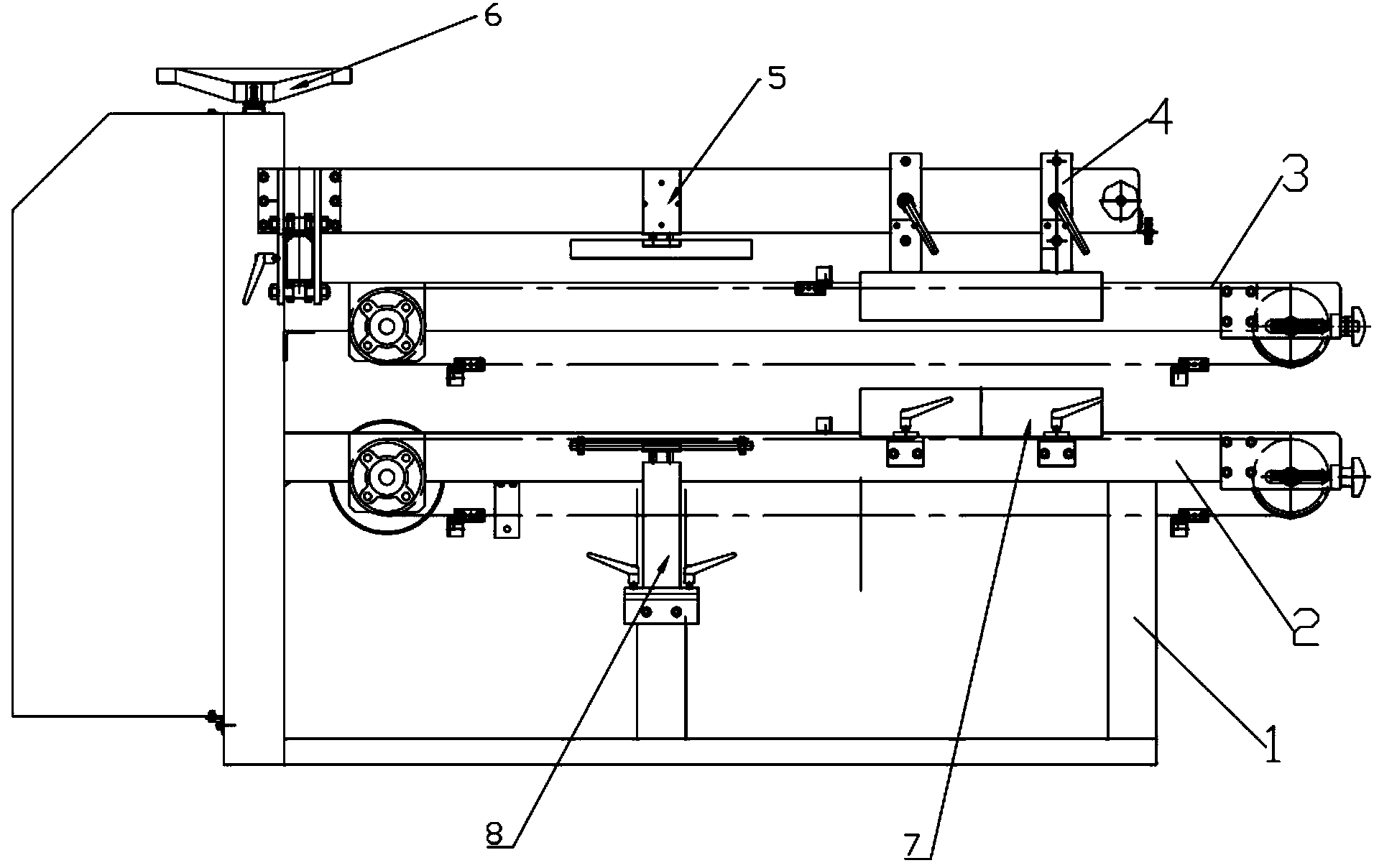

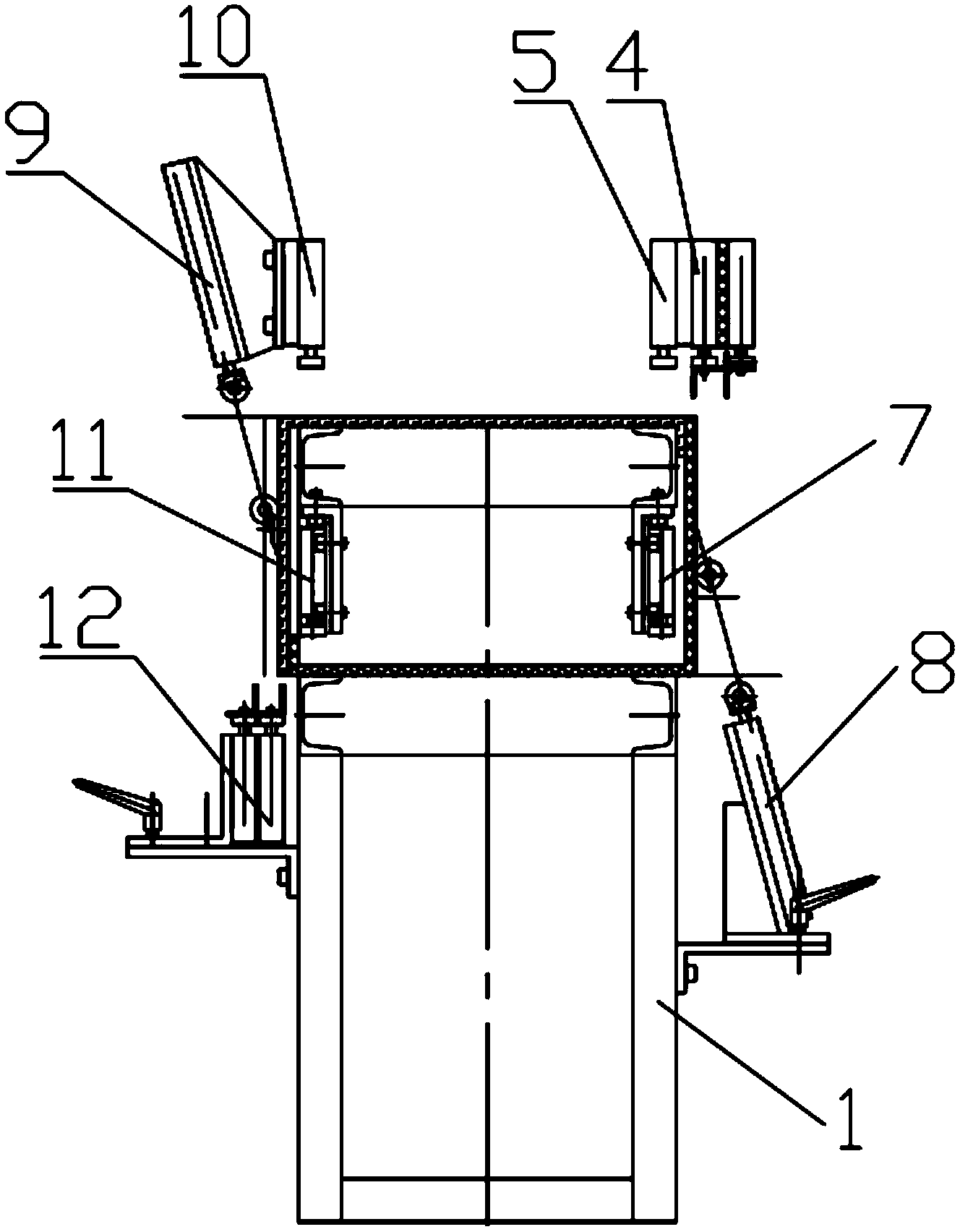

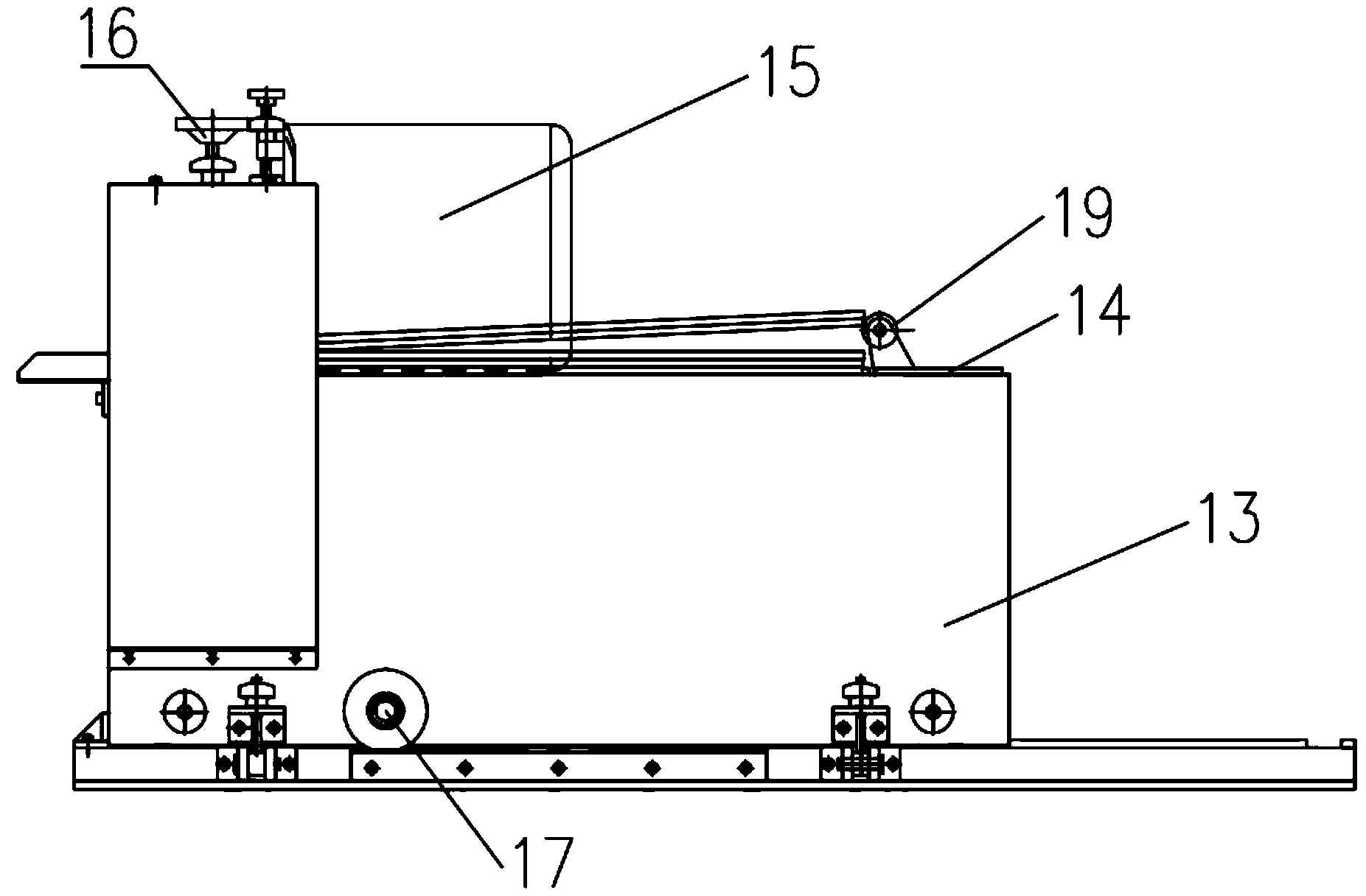

[0026] The invention discloses a carton automatic nailing machine for binding cartons composed of two carton sheets (see attached Figure 6 ), the two carton sheets are provided with binding edges for binding on one side, and during the binding process, the binding edges can be overlapped and bound (see the attached carton structure for details) Figure 1-2 hatched part in the middle), including carton folding forming part (see attached Picture 1-1 , 1-2 ), the upper paper feeding parts located on both sides of the feeding end of the carton folding forming part (see attached Figure 3-1 , 3-2 ) and the lower paper feed section (see attached diagram 2-1 , 2-2 ) and the upper nail box parts located on both sides of the discharge end of the carton folding forming part (refer to the attached Figure 5 ) and the lower nail box (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com