Method for green synthesis of nano-gold by using water extract of eucommia ulmoides

A water extract, green synthesis technology, applied in nanotechnology and other directions, can solve problems such as environmental and human harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of method of utilizing Eucommia ulmoides water extract green synthesis nano-gold of the present embodiment, its specific steps are as follows:

[0024] Step 1: Wash Eucommia ulmoides, dry at 60°C, and pulverize into powder;

[0025] Step 2: Weigh 20mg of Eucommia powder into a beaker, add 100mg of water, place in a water bath at a constant temperature of 80°C for 30 minutes, and filter;

[0026] Step 3: centrifuging the obtained solution at a high speed of 12000r / min to obtain the Eucommia water extract;

[0027] Step 4: mix the chloroauric acid solution with the Eucommia ulmoides water extract, the concentration of chloroauric acid in the mixed solution is 10 -3 mol / L, after mixing evenly, place in a constant temperature water bath, the temperature is controlled at 40°C, the reaction time is controlled at 20min, and the particle size of the prepared nano gold is 10-40nm.

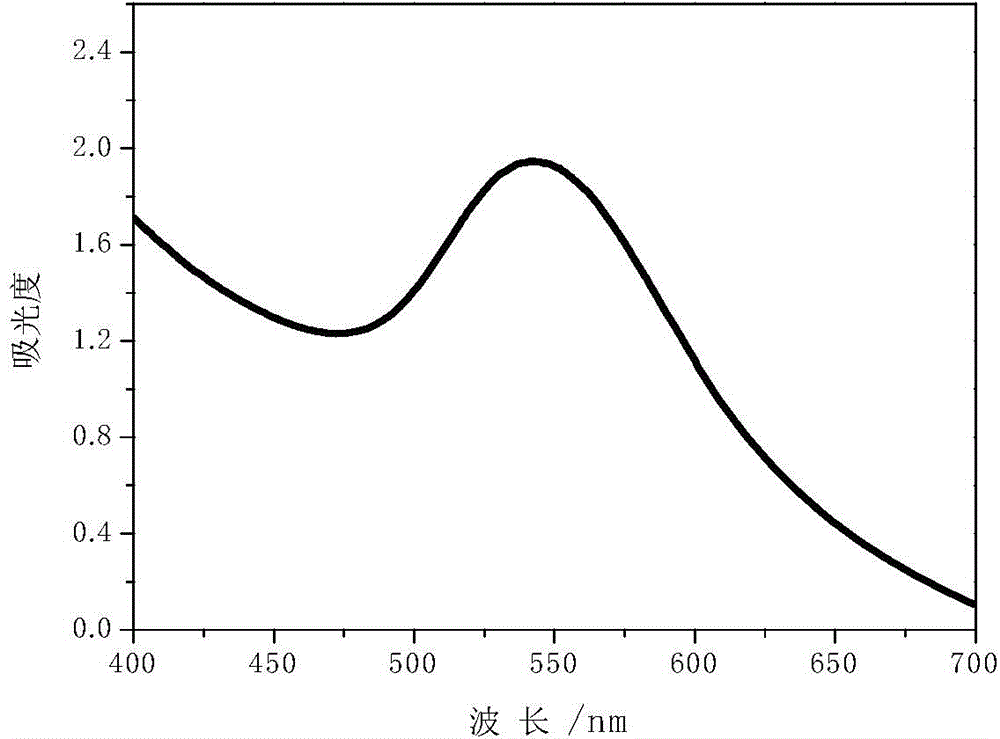

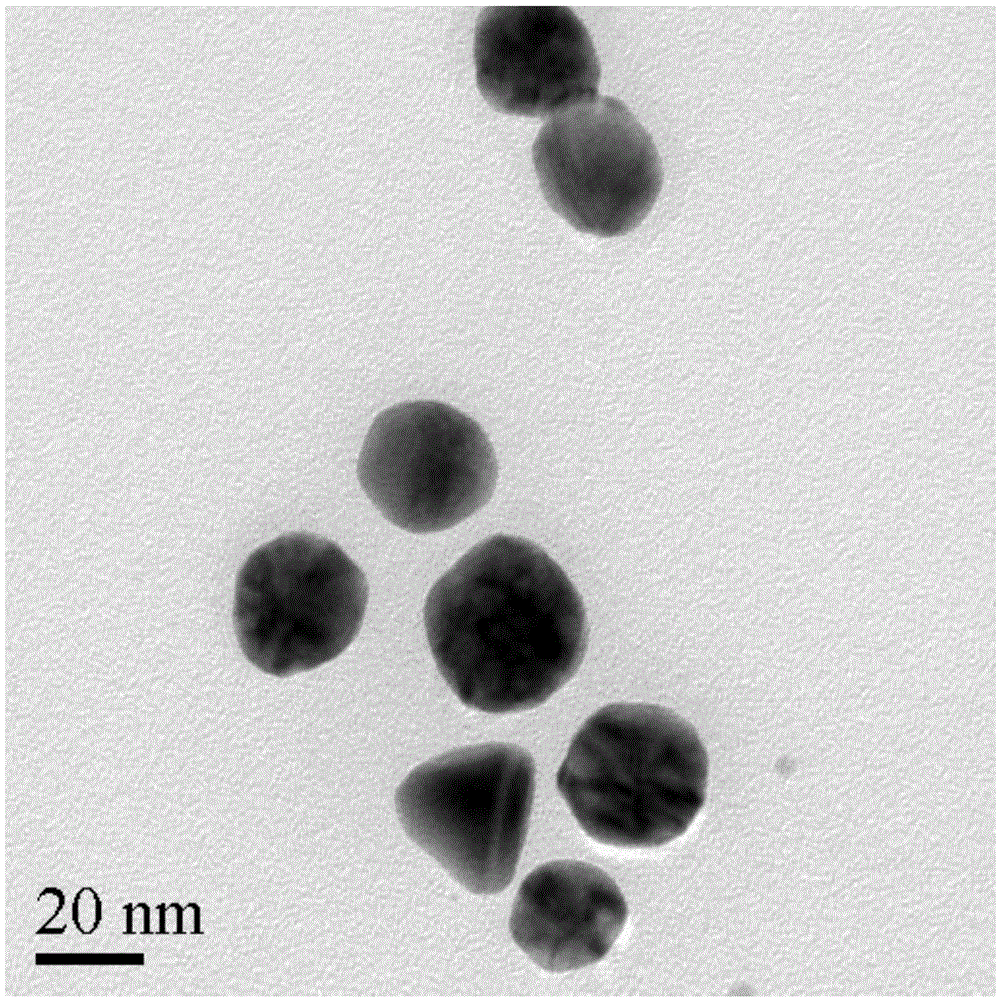

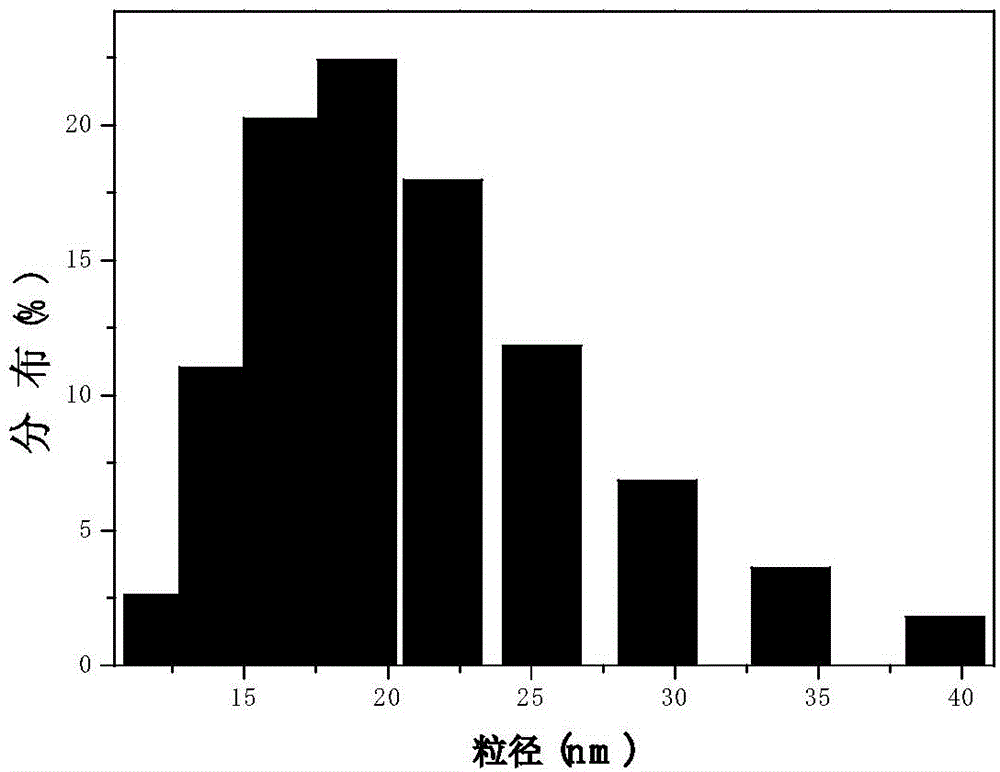

[0028] Such as figure 1 Shown is the nano-gold prepared in Example 1 and ...

Embodiment 2

[0031] Embodiment 2: A kind of method of utilizing Eucommia ulmoides water extract green synthesis nano-gold of the present embodiment, its specific steps are as follows:

[0032] Step 1: Wash Eucommia ulmoides, dry at 60°C, and pulverize into powder;

[0033] Step 2: Weigh 20mg of Eucommia powder into a beaker, add 100mg of water, place in a water bath at a constant temperature of 80°C for 30 minutes, and filter;

[0034] Step 3: centrifuging the obtained solution at a high speed of 12000r / min to obtain the Eucommia water extract;

[0035] Step 4: mix the chloroauric acid solution with the Eucommia ulmoides water extract, the concentration of chloroauric acid in the mixed solution is 10 -4 mol / L, after mixing evenly, place in a constant temperature water bath, the temperature is controlled at 20°C, the reaction time is controlled at 30min, and the particle size of the prepared nano gold is 5-20nm.

Embodiment 3

[0036] Embodiment 3: A kind of method of utilizing Eucommia ulmoides water extract green synthesis nano-gold of the present embodiment, its specific steps are as follows:

[0037] Step 1: Wash Eucommia ulmoides, dry at 60°C, and pulverize into powder;

[0038] Step 2: Weigh 20mg of Eucommia powder into a beaker, add 100mg of water, place in a water bath at a constant temperature of 80°C for 30 minutes, and filter;

[0039] Step 3: centrifuging the obtained solution at a high speed of 12000r / min to obtain the Eucommia water extract;

[0040] Step 4: mix the chloroauric acid solution with the Eucommia ulmoides water extract, the concentration of chloroauric acid in the mixed solution is 10 -2 mol / L, after mixing evenly, place in a constant temperature water bath, the temperature is controlled at 60°C, the reaction time is controlled at 5min, and the particle size of the prepared nano gold is 30-60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com