Catalytic oxidation-based ozone deodorizing system

A technology of catalytic oxidation and oxygen production system, applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems that do not conform to the development model of energy saving, reproductive and immune dysfunction, endocrine disorders, etc., and achieve a solution Occupational health and physical and mental health problems, and the effect of solving atmospheric environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

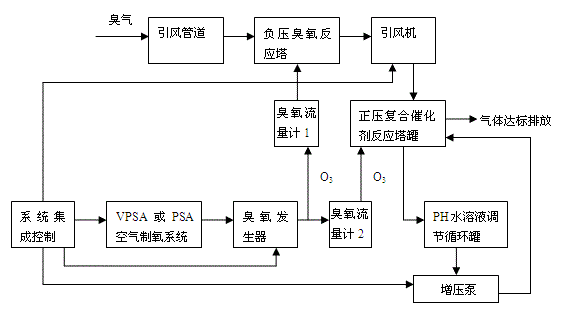

[0016] Such as figure 1 As shown, a catalytic oxidation ozone deodorization system includes a negative pressure ozone reaction tower, a positive pressure composite catalyst reaction tower, a pH aqueous solution adjustment circulation tank, a PLC microcomputer controller, a VPSA air oxygen generation system and an ozone generator;

[0017] The positive pressure composite catalyst reaction tower contains a composite catalyst, and the composite catalyst is an aluminum oxide ceramic hollow sphere carrier with loads on the skeleton, the loads are rare earth, Pt and Pb, and the aluminum oxide ceramic hollow The mass fractions of spherical carrier, rare earth, Pt and Pb are respectively: 35-45%, 18-22%, 15% and 22-28%;

[0018] The positive pressure composite catalyst reaction tower is equipped with a spiral nozzle, the air inlet of the negative pressure ozone reaction tower is connected to the air duct, and the air outlet is connected to the air inlet of the positive pressure compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com