Novel multiple-effect evaporation device

A new type of multi-effect evaporation technology, which is applied in the field of new multi-effect evaporation devices, can solve the problems of high energy consumption, low heat transfer coefficient, and large footprint of waste water evaporators, and achieve rapid heat transfer, improved evaporation efficiency, and easy The effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

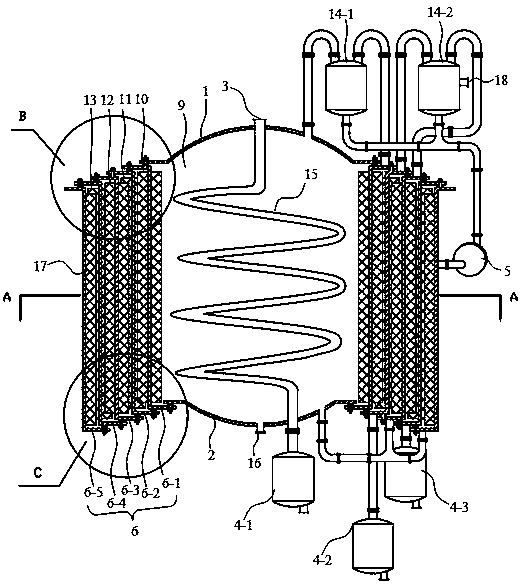

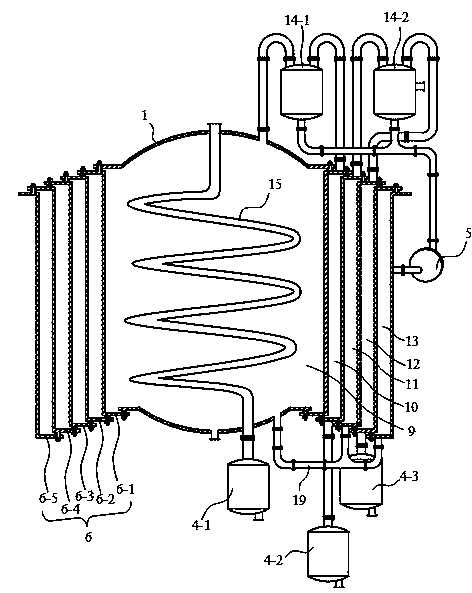

[0036] Below, with reference to accompanying drawing and embodiment the novel multi-effect evaporator of the present invention is described in detail:

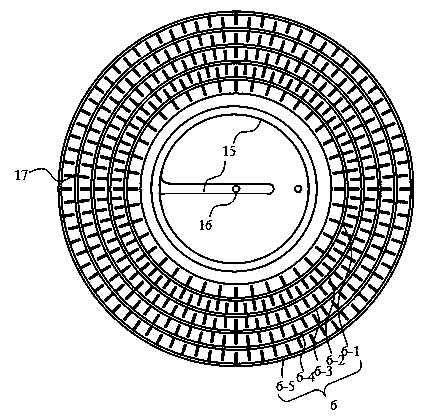

[0037] Such as Figure 1-7 As shown, a new type of multi-effect evaporation device includes an upper cover 1 and a lower cover 2, and the upper cover 1 and the lower cover 2 are respectively installed on the upper and lower ends of the No. I sleeve 6-1 located in the center. The No. I sleeve 6 -1, No. II sleeve 6-2, No. III sleeve 6-3, No. IV sleeve 6-4, and No. V sleeve 6-5 are arranged concentrically from the inside to the outside and at a certain distance to form a sleeve structure6.

[0038] Among them, the No. 1 sleeve 6-1 located in the center forms a first-effect material liquid chamber 9 with the upper cover 1 and the lower cover 2, and the cavities formed between the other sleeves are the second-effect heating chamber 10, Second-effect feed liquid chamber 11 , three-effect heating chamber 12 and three-effect feed li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com