Fabrication method for hydrogel/macromolecule polymer film muscular tissue support

A high-molecular polymer and muscle tissue technology, applied in the fields of muscle, medical science, ligaments, etc., can solve the problems of difficult preparation process, hard to heal wounds, limited sources, etc., to solve the construction of three-dimensional vascular network, realize the fixed function, prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

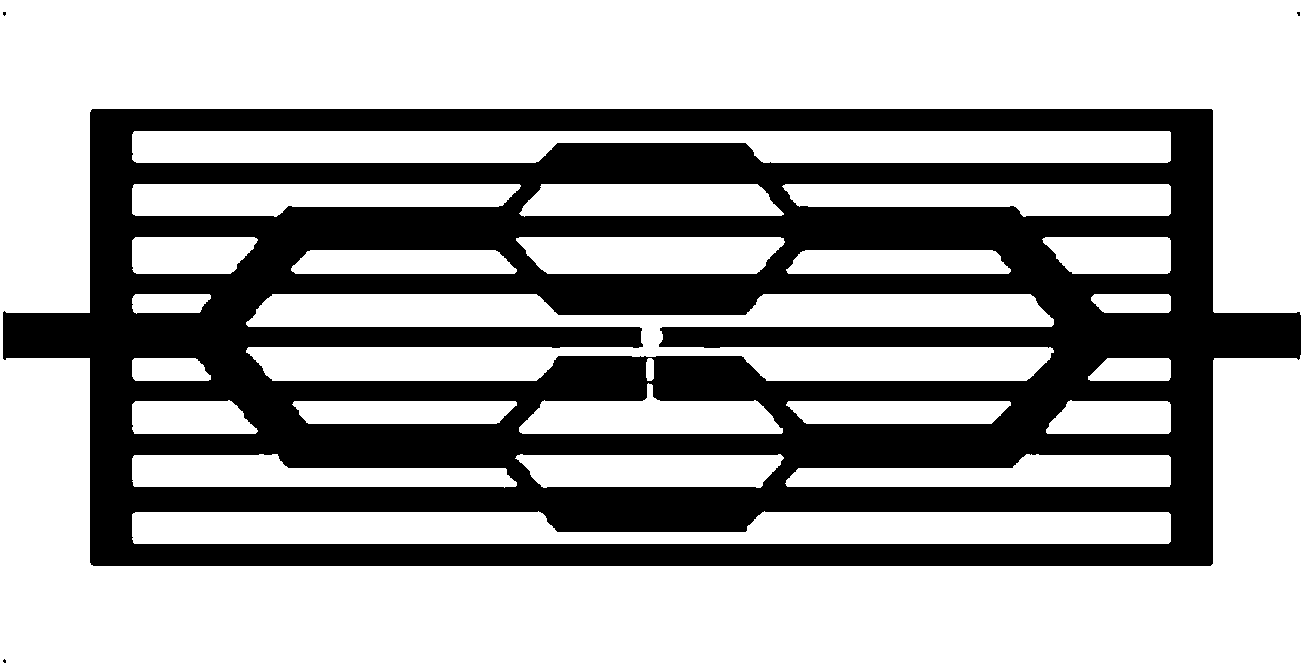

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

[0029] refer to figure 1 , the manufacture method of hydrogel / polymer film muscle tissue support of the present invention comprises the following steps:

[0030] 1) Draw the internal pipeline structure model of the hydrogel / polymer film muscle tissue scaffold, and then prepare N resin parts by light-curing rapid prototyping machine according to the internal pipeline structure model;

[0031] 2) Prepare the silica gel solution, then fix the N resin parts obtained in step 1) on the silica gel mold respectively, then inject the prepared silica gel solution into the silica gel mold, and then remove the air bubbles in the silica gel solution by vacuuming, and let it stand Release the mold after curing to obtain an N-layer silicone mold;

[0032] 3) preparing a high molecular polymer PLGA solution, and then electrospinning the prepared high molecular polymer PLGA solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com