Biocide-algaecide for circulating water and preparation method thereof

A technology of bactericidal algicide and circulating water, applied in herbicides and algicides, botanical equipment and methods, biocides, etc., can solve the problems of difficult microorganisms, complex components, fouling, etc. The effect of strong inactivation and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

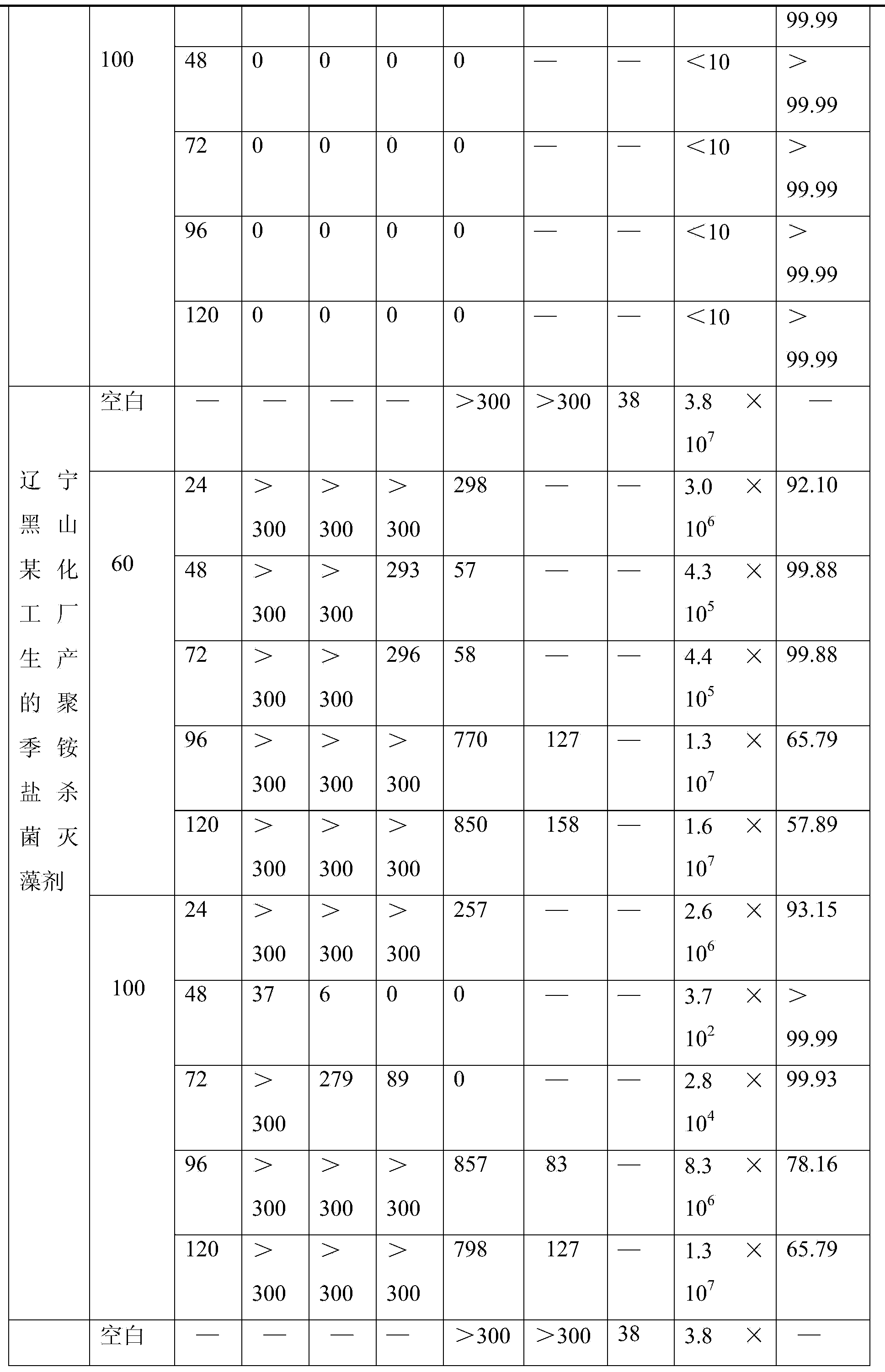

Examples

Embodiment 1

[0026] The raw materials are as follows:

[0027]

[0028] Add deionized water, polydichloroethyl ether tetramethylethylenediamine, fatty alcohol polyoxyethylene ether, hydroxyethylidene diphosphonic acid, and hydrogen peroxide into the same reaction kettle in sequence according to the component content. Stir for 60 minutes and serve.

Embodiment 2

[0030] The raw materials are as follows:

[0031]

[0032]

[0033] Add deionized water, polydichloroethyl ether tetramethylethylenediamine, fatty alcohol polyoxyethylene ether, hydroxyethylidene diphosphonic acid, and hydrogen peroxide into the same reaction kettle in sequence according to the component content. Stir for 30 minutes and serve.

Embodiment 3

[0035] The raw materials are as follows:

[0036]

[0037] Add deionized water, polydichloroethyl ether tetramethylethylenediamine, fatty alcohol polyoxyethylene ether, hydroxyethylidene diphosphonic acid, and hydrogen peroxide into the same reaction kettle in sequence according to the component content. Stir for 50 minutes and serve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com