Ripple wave suppressor circuit of program-controlled direct-current power supply

A ripple suppressor and DC power supply technology, applied in electrical components, output power conversion devices, etc., can solve the problem that the power loss cannot be further reduced, the power consumption of the post-stage voltage regulator circuit is large, and the front and rear stages cannot achieve synchronous tracking adjustment. and other problems, to achieve good application value, efficient load point adjustment, and improve the effect of dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

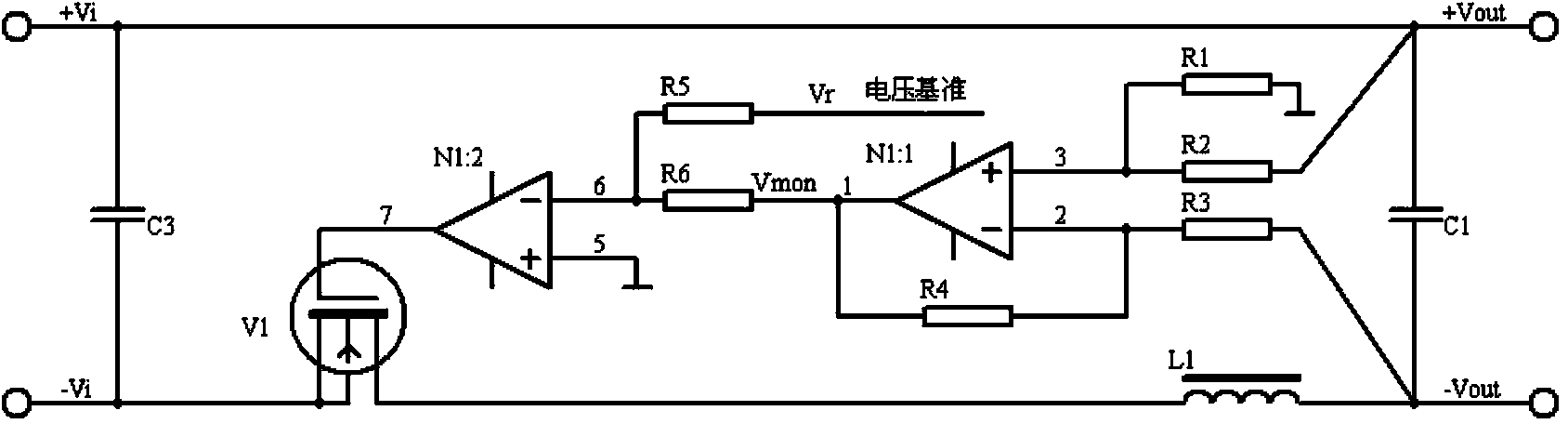

[0028] The present invention requires that the program-controlled voltage output is 0-20V, and the maximum output current is 10A. Since the output range of the circuit DAC is -5V-0V, the values of the resistors R1, R2, R5 and R6 are related to the output voltage Vo and the working range of the operational amplifier N1 Regarding, because the power supply voltage of the operational amplifier is 12V, in order to ensure good adjustment characteristics, the maximum value of Vmon is determined to be 10V, so k1 is taken as 0.5, k2 is taken as 0.5, and the resistance value R1 is selected as 20k, R2 as 10k, and R5 as 10k. R6 is 10k, and the accuracy is 0.1%. metal film resistors. The operational amplifier N1 adopts high-precision dual operational amplifier LT1013, which can complete the precise adjustment of the active voltage; the adjustment tube V1 adopts HUF75345P, with a typical on-resistance of 7mΩ, which can reduce the voltage drop of 10A to within 200mV, effectively improving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com