Wire lifting device for replacing plus and minus 800 kilovolt electric transmission line composite insulator string in charged mode

A technology for composite insulators and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of time-consuming and material-consuming processing, complicated operation, and increased costs, and achieve the effect of shortening the operation process, simple and fast operation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

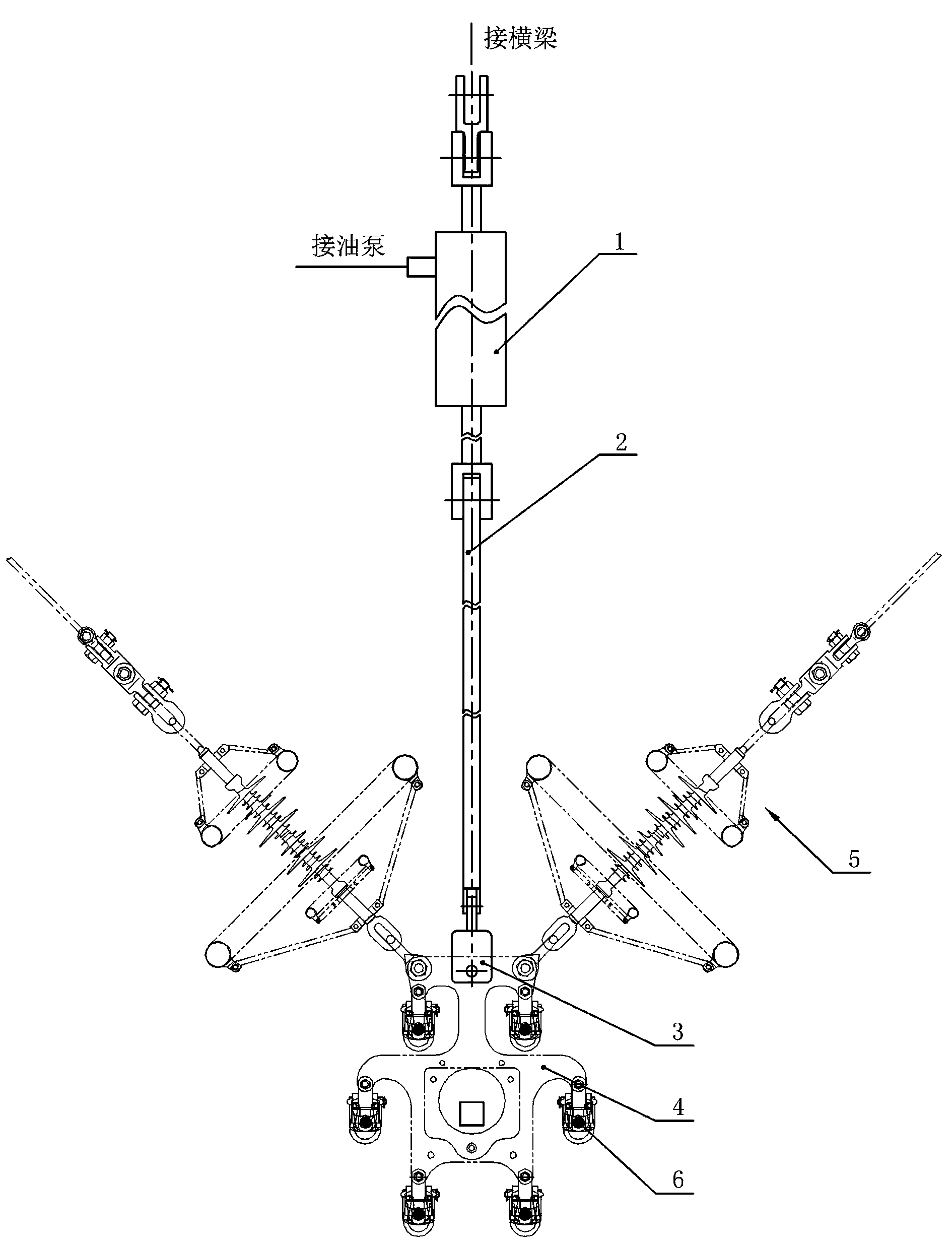

[0015] like Figure 1 to Figure 3 As shown, the wire lifting device for live replacement of ±800 kV transmission line composite insulator strings disclosed in the present invention includes an oil cylinder 1 and an insulating pull rod 2 connected to its lower end, and the lower end of the insulating pull rod 2 is connected with a wire lifting member 3.

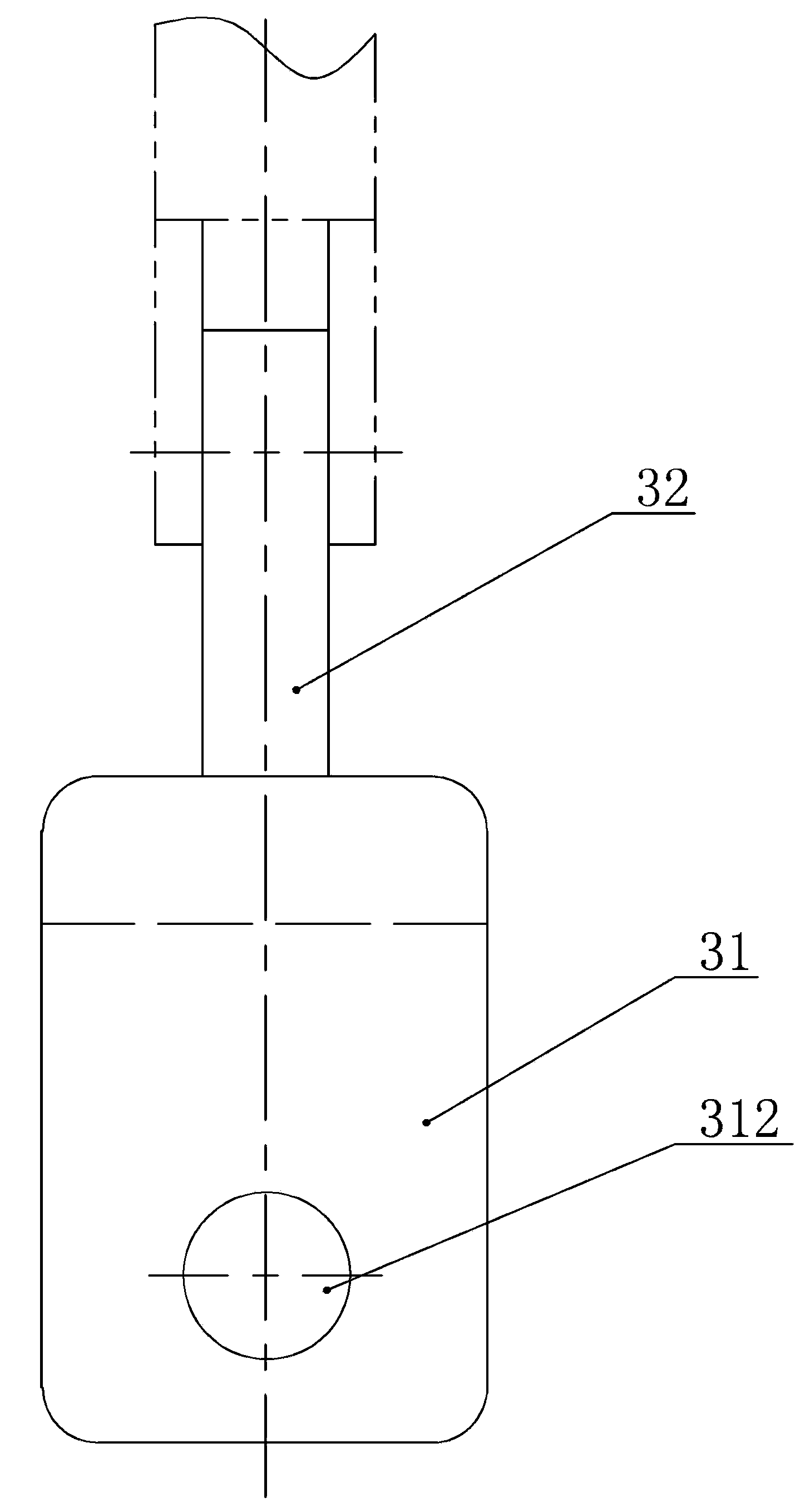

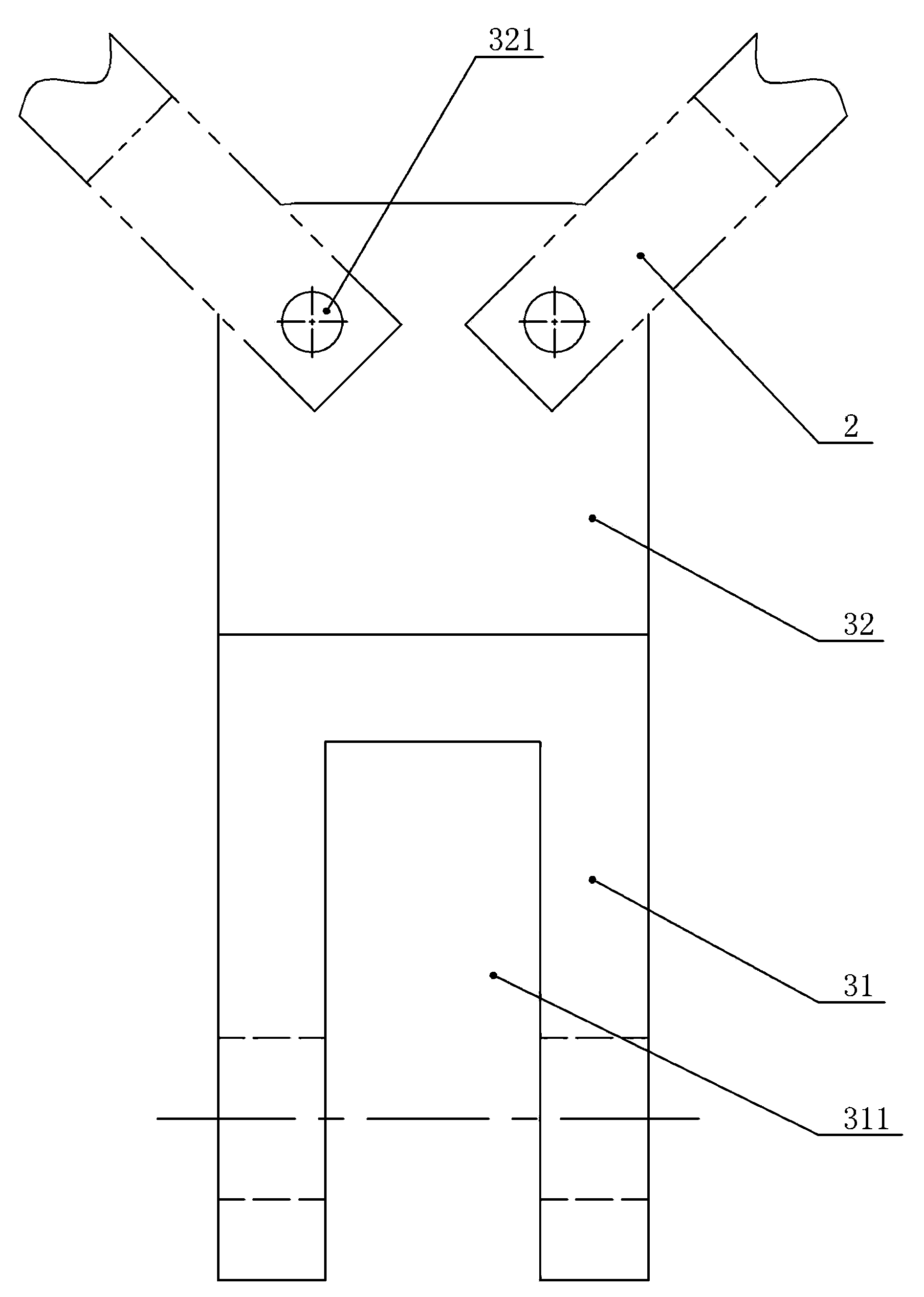

[0016] The wire lifting member 3 includes a clip joint 31 connected to the upper end of the connecting plate 4 and a connecting plate 32 whose upper end is used for connecting the insulating pull rod 2 . The clip joint 31 is a U-shaped joint, and the center of its length direction has a concave notch 311, and there are through holes 312 perpendicular to the notch on the entities on both sides of the notch. The notch 311 blocks the connecting plate 4 and passes through it The fasteners of the through holes 312 on both sides are connected and fastened. There are two connecting holes 321 along the thickness direction on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com