Manganese dioxide/carbon nanocomposite, and preparation method and application thereof

A manganese dioxide, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high temperature, unsuitable for industrial production, high energy consumption, and achieve short time, Wide selection of effects with simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 15.64mg of hydroxyl-modified multi-walled carbon nanotubes to 50mL of 0.36mmol / L potassium permanganate solution, disperse it by ultrasonication for 30min, then add the mixed solution to 50mL of 0.84mmol / L manganese sulfate solution, Then quickly add 50 mL of 0.01 mol / L sulfuric acid solution, and stir rapidly at room temperature for 1 h. The resulting precipitate was washed with deionized water to neutrality, and vacuum-dried at 65° C. to obtain manganese dioxide flakes grown on carbon nanotubes.

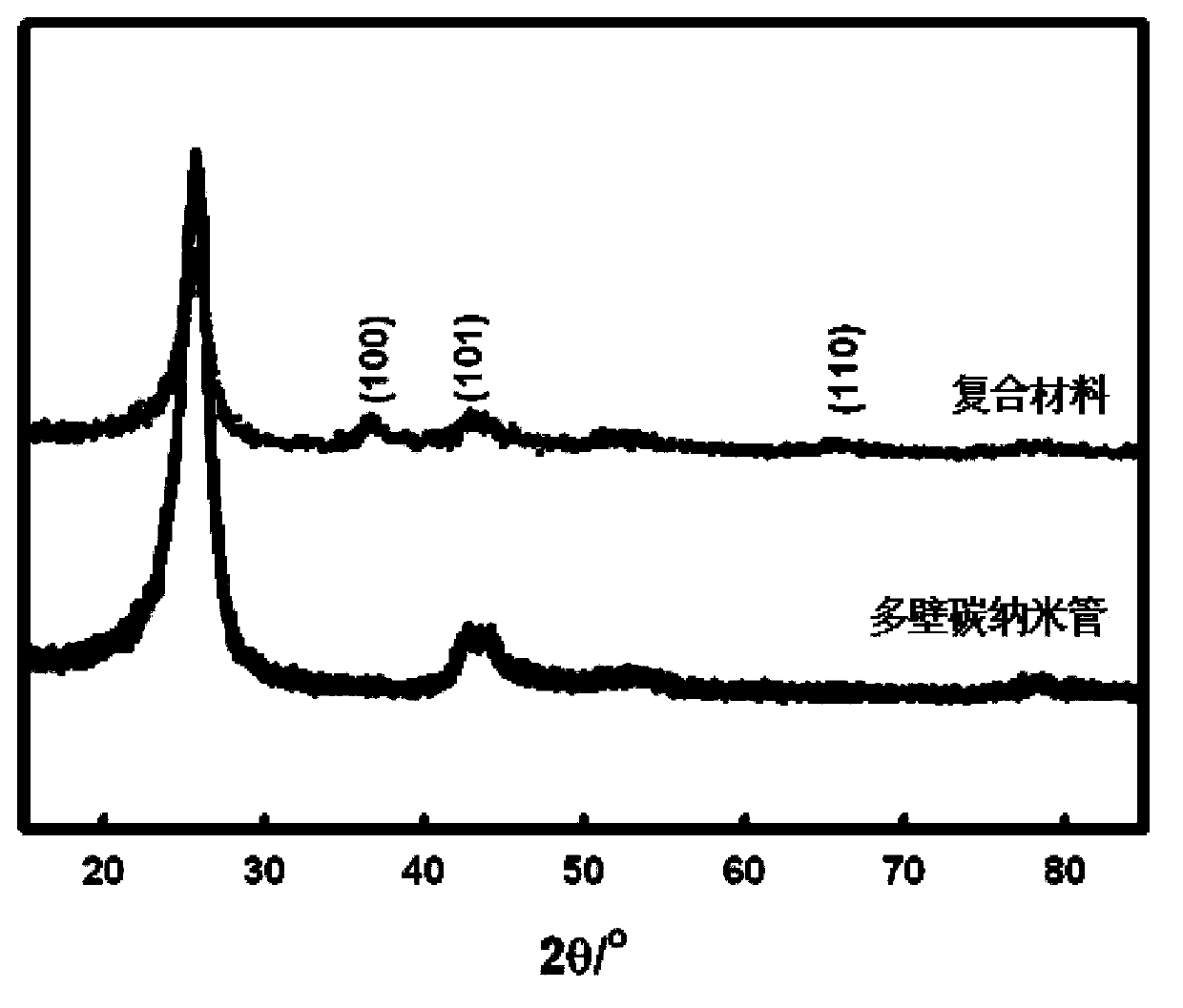

[0039] Such as figure 1 , the XRD spectrum of the product obtained in Example 1 of the present invention and the hydroxyl-modified multi-walled carbon nanotubes, the diffraction peaks at 36.73°, 43.68°, and 65.84° correspond to ε-MnO 2 The (100), (101), (110) crystal planes prove that manganese dioxide has grown on carbon nanotubes.

[0040] Such as figure 2 , Transmission electron micrographs of hydroxyl-modified multi-walled carbon nanotubes, the length of carbon n...

Embodiment 2

[0046] Carbon carrier selection: Add 15.64mg of carbon black (Ketjen black EC-600J) to 50mL of 0.36mmol / L potassium permanganate solution, ultrasonically disperse it for 30min, and then add the mixture to 50mL of 0.84mmol / L To the manganese sulfate solution, quickly add 50mL of 0.01mol / L sulfuric acid solution, and stir rapidly at room temperature for 1h. The resulting precipitate was washed to neutral with deionized water, and vacuum-dried at 65°C to obtain manganese dioxide flakes grown on EC-600J carbon black.

Embodiment 3

[0048] Temperature selection 60°C: Add 10.59g of hydroxyl-modified multi-walled carbon nanotubes to 50mL of 649.35mmol / L potassium permanganate solution, ultrasonically disperse it for 30min, and then add the mixture to 50mL of 1500mmol / L In the manganese sulfate solution, quickly add 50 mL of 0.01 mol / L sulfuric acid solution, reflux at 60 ° C, and stir rapidly for 1 h. The obtained precipitate was washed with deionized water to neutrality, and vacuum-dried at 65° C. to obtain manganese dioxide flakes grown on carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com