Wind energy anti-torque cable

A cable and wind energy technology, applied in the field of wind energy torsion-resistant cables, can solve the problems of shortened cable life, high cable performance requirements, long service life of fans, etc., and achieve good oxidation resistance, good physical and mechanical properties and flexibility, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

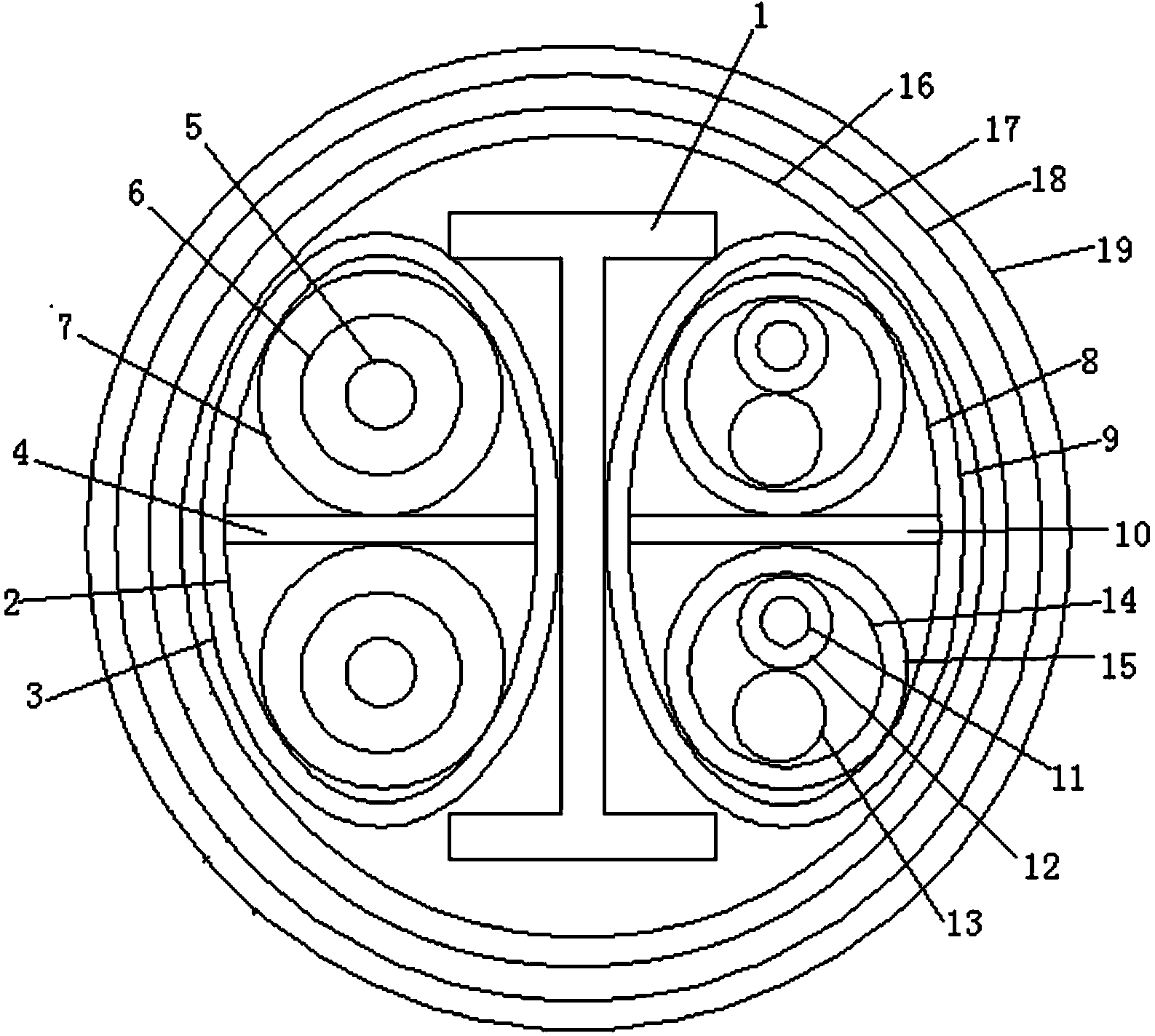

[0012] Such as figure 1 As shown, a wind energy torsion-resistant cable includes a cable core, and the cable core includes an I-shaped silicone skeleton 1, and the main wire core and the control wire are respectively placed on the left and right sides of the I-shaped silicone skeleton 1. core, the main wire core includes an oval silica gel skeleton-2, a tension band-3 is wrapped on the outside of the oval silica gel skeleton-2, and an elastic backing plate-4 is placed inside the oval silica gel skeleton-2, The main conductor 5 is respectively placed on both sides of the elastic backing plate 4, and the outer side of the main conductor 5 is coated with a polyimide insulating layer 6 and an aluminum-plastic composite film shielding layer 7 in turn, and the control wire core includes The oval silica gel skeleton II 8 is wrapped with a tensile band II 9 outside the oval silica gel skeleton II 8, and an elastic backing plate II 10 is placed inside the oval silica gel skeleton II 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com