Small quick heater

A heater, fast technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as difficult miniaturization, and achieve simple and reliable fixing methods, reduced replacement times, and high heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

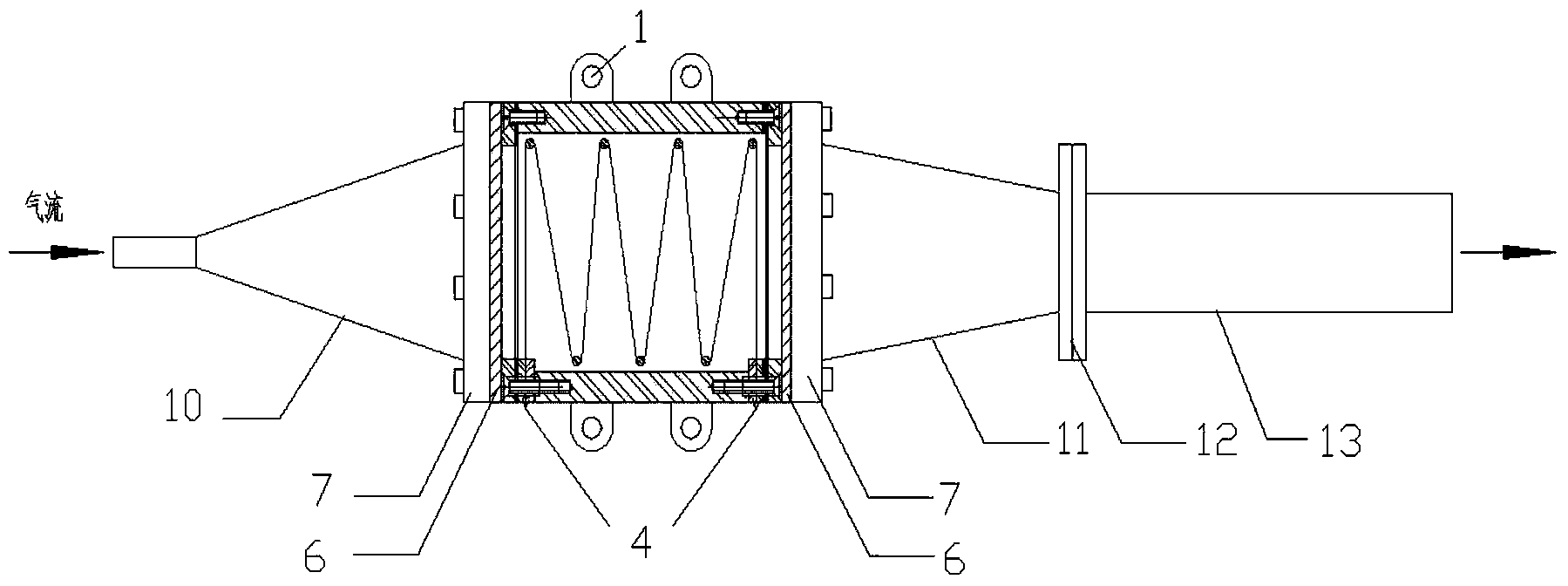

[0020] The present embodiment is a kind of small fast heater.

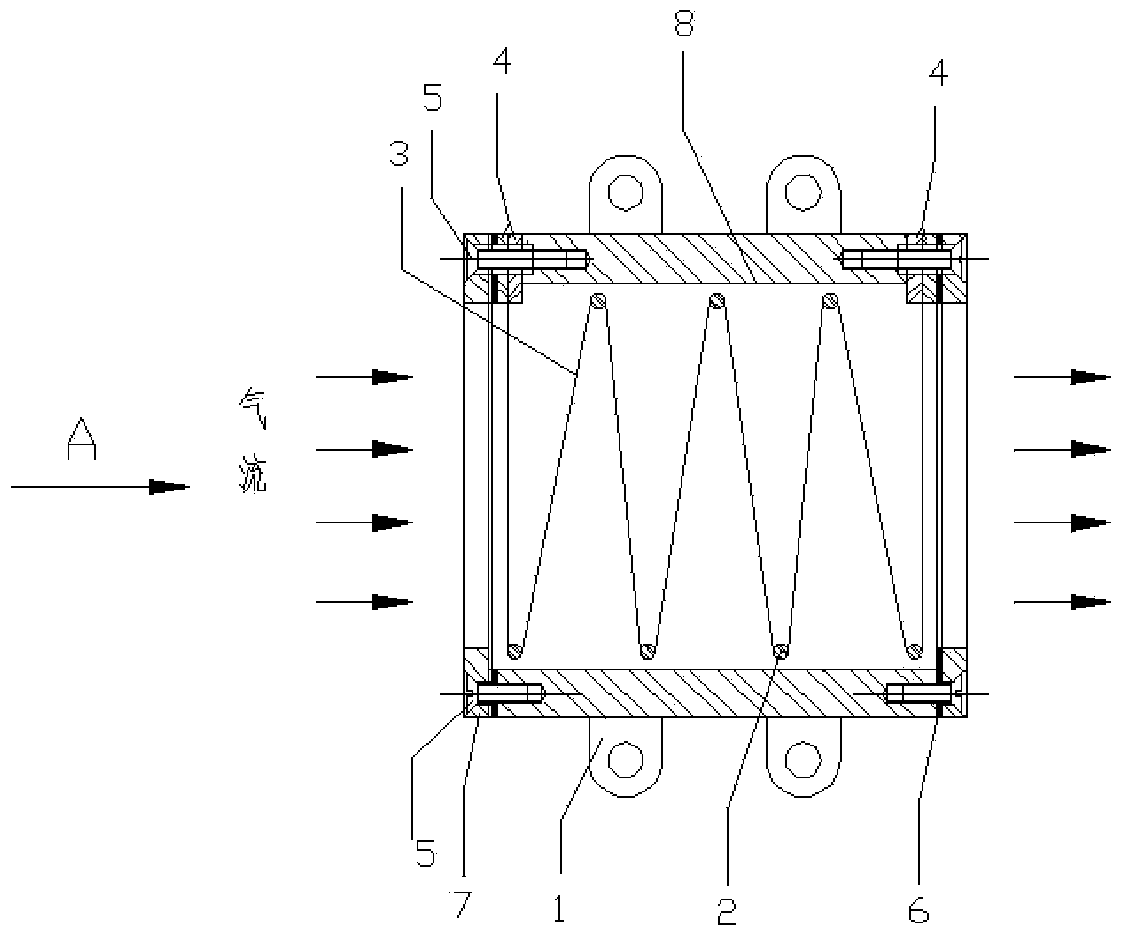

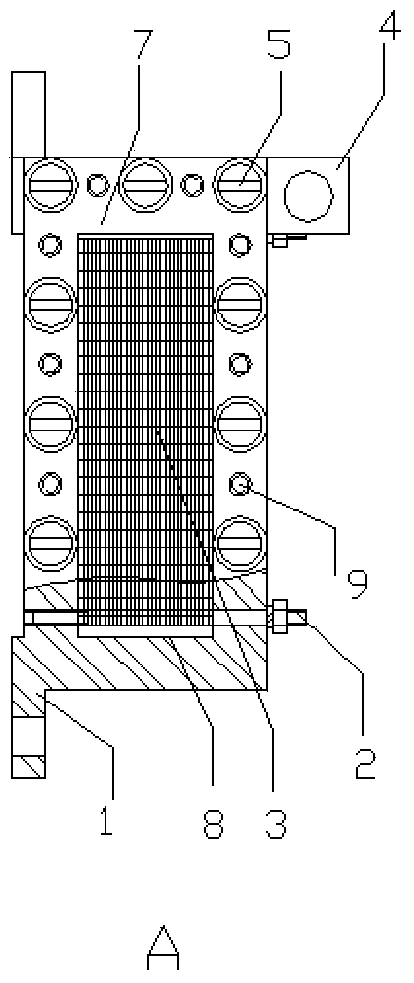

[0021] refer to figure 1 , figure 2 , The fast heater in this embodiment is composed of a shell 1, an insulating stud 2, a heating net 3, an electrode 4, an insulating screw 5, an asbestos gasket 6, a flange 7, and an insulating layer 8, and a multilayer folded wire mesh is used as the Heating element.

[0022] The heating net 3 is tightened and fixed along the insulating studs 2 on both sides of the channel of the shell 1, and the heating net 3 forms a multi-layer M-shaped structure along the channel, and the heating net 3 is perpendicular to the flow direction of the fluid working medium; the shell 1 There are electrodes 4 at both ends to fasten the heating grid 3, and there are two electrodes 4 at both ends of the heating grid 3 to ensure the reliable power supply of the heating grid 3, and the power supply end of the electrodes 4 and the flange 7 are fastened on the shell 1 through insulating screws 5; Hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com