Rotary type exhaust gas processing device

A waste gas treatment device and technology for waste gas treatment, which are applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of increased energy consumption of equipment, waste of manpower, inability to eliminate the impact of damper valve gas and increased concentration of exhaust gas, etc. , to achieve the effect of temperature and maintenance saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

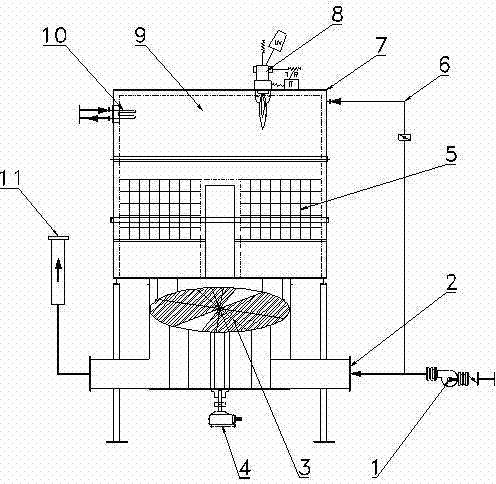

[0018] Such as figure 1 As shown, a rotary exhaust gas treatment device includes a chamber body 7, the upper end of the chamber body 7 is an exhaust gas treatment area 9, and the lower end is a heat storage and heat exchange area 5. Rotary wheel 3, the two sides below the rotary wheel 3 are respectively provided with an air inlet pipe 2 and an exhaust air pipe 11, the air inlet of the air inlet pipe 2 is provided with an air inlet fan 1, and the waste gas treatment area 9 Also be provided with heating burner 8 inside. The rotary wheel 3 rotates continuously under the drive of the rotary reducer 4, and periodically transports the exhaust gas to the heat storage and heat exchange area 5, which overcomes the shock and vibration caused by switching the air duct switch with the valve before; it also keeps the exhaust gas treatment continuous To avoid the discharge of untr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com