Flat plate type argon blowing joint

A flat type, joint body technology, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., can solve the problems of excessively high tolerances for joint positioning, easy collisions, inconvenient use, etc., and achieve allowable deviations Low requirements, guaranteed sealing effect, and less exposed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

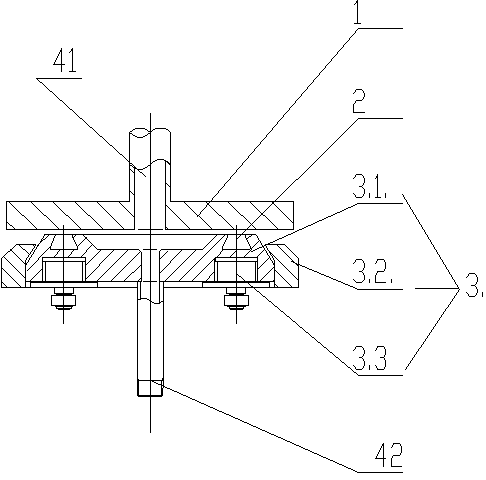

[0020] As shown in the figure, a flat type argon blowing joint is characterized in that it consists of an upper part 1 of the argon blowing joint, a sealing ring 2, a lower part 3 of the argon blowing joint, and connecting pipes 41 and 42; the upper part 1 of the argon blowing joint is fixedly installed on On the ladle, it is connected to the argon blowing element through the connecting pipe 41.

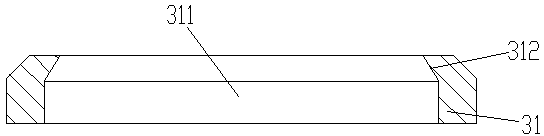

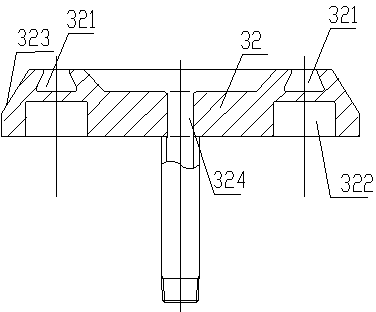

[0021] As shown in the figure, the lower part 3 of the argon blowing joint includes a fixing seat 31 , a joint body 32 and a pressing force adjustment assembly 33 . The outside of the fixed seat 31 is square, and the interior of the fixed seat 31 is provided with a circular concave hole 311, and the joint body 32 is placed in the circular concave hole 311, and the top of the joint body 32 is provided with an annular groove 321. The section of the groove 321 is trapezoidal, and the sealing ring 2 is installed in the annular groove 321. The sealing ring 2 is located at the connection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com