Stop valve

A globe valve and valve core technology, which is applied in the field of air conditioner globe valves, can solve the problems that the collar and the valve core cannot be effectively fitted, the globe valve fails, and the deviation of the coaxiality of the collar 3 is too large, so as to reduce the thermal deformation. Influence, stable sealing effect, effect of expanding heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

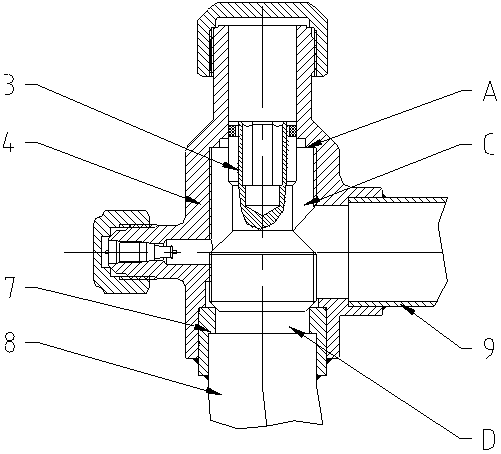

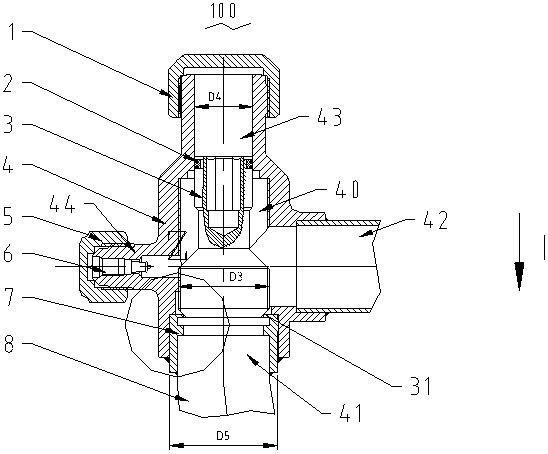

[0021] see Figure 2 to Figure 4 , the structure and assembly method of the shut-off valve 100 of the present invention will be described below with reference to the accompanying drawings.

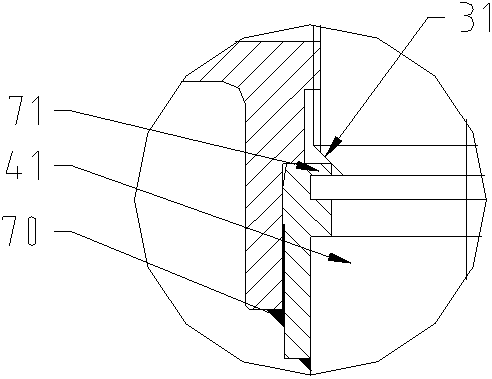

[0022] The shut-off valve 100 of the present invention includes a cavity 40 formed by assembling a valve seat 4 and a valve core 3 and a collar 7 installed on the valve seat 4. The valve seat 4 has a medium inlet 41 and a medium outlet 42. The collar 7 is provided with a first sealing ring part 71 located between the medium inlet 41 and the medium outlet 42, the valve core is located between the medium inlet 41 and the medium outlet 42 and can cooperate with the first sealing ring part 71 To realize the on-off of the medium inlet 41 and the medium outlet 42, the valve core 3 is also provided with a tapered surface 31 that cooperates with the first sealing ring part 71, and the collar 7 has a normal hole diameter D1, a normal inner wall thickness S1 and a formed The second aperture D2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com