Centrifugal speed adjustment tail vane deflection yaw type wind generating set

A technology for wind turbines and generators, used in wind turbines, wind turbine control, wind power generation, etc., can solve the problems of poor anti-vibration performance, large losses, easy damage to wind turbines, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0029] The present invention covers any alternatives, modifications, equivalent methods and schemes made on the spirit and scope of the present invention. In order to provide the public with a thorough understanding of the present invention, specific details are set forth in the following preferred embodiments of the present invention, but those skilled in the art can fully understand the present invention without the description of these details.

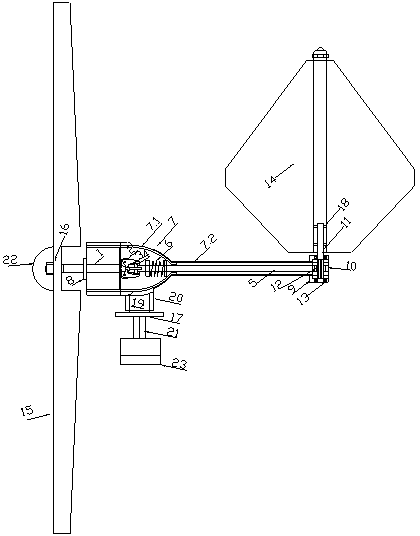

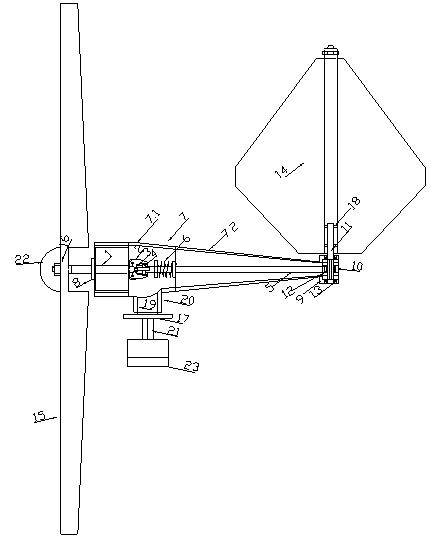

[0030] Such as figure 1 and 2 As shown, the centrifugal speed regulation folding tail yaw type wind power generating set of the present invention comprises a wind wheel, a transmission shaft 1, a tail rudder 14, a tail rudder push-pull rod 5 and a tail rudder mounting frame 9, and the tail rudder 14 is installed on the tail On the rudd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com