Automatic aluminum alloy door and window assembling workbench

A technology for aluminum alloy doors, windows, and workbenches, which is applied to drive devices, metal processing equipment, and metal processing machinery parts, etc., can solve problems such as labor-intensive, low product quality, and low production efficiency, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

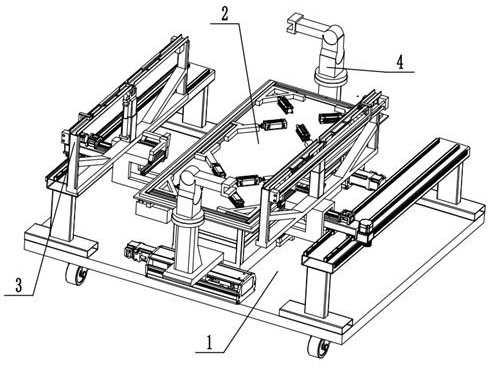

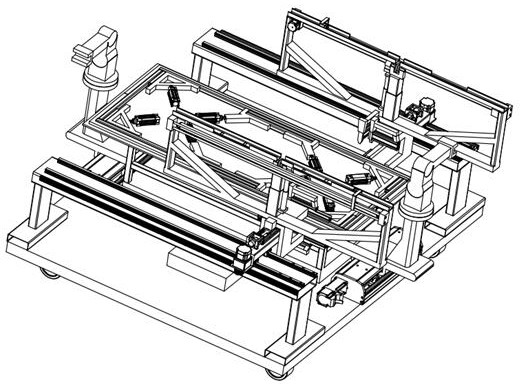

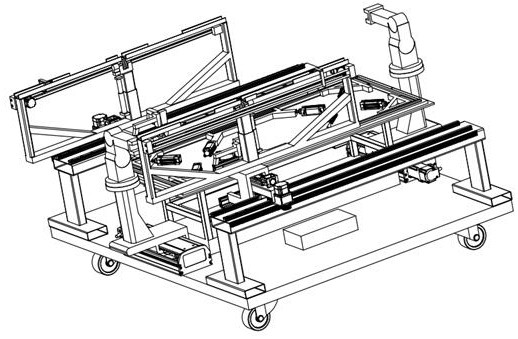

[0029] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 The shown automatic aluminum alloy door and window assembly workbench includes: a bottom welding mechanism 1, a door and window fixing mechanism 2, a cutting and feeding mechanism 3, a clamping and discharging mechanism 4, and the bottom welding mechanism 1 includes: a bottom plate 101, wheels 102, control device 103, bracket 107, laser welding mechanism and horizontal movable mechanism; the lower end surface of the base plate 101 is fixedly connected with the upper end surface of the wheel 102; the controller 103 is fixedly installed on the upper end surface of the base plate 101, and the controller 103 includes: an operation panel and an operation handle and the central processing unit; the control program can be written in the central processing unit, the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com