Vegetable sowing machine

A planter and vegetable technology, applied in the agricultural field, can solve the problems of low versatility, change, and inability to meet the spacing seeding, etc., and achieve the effect of improving the versatility and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

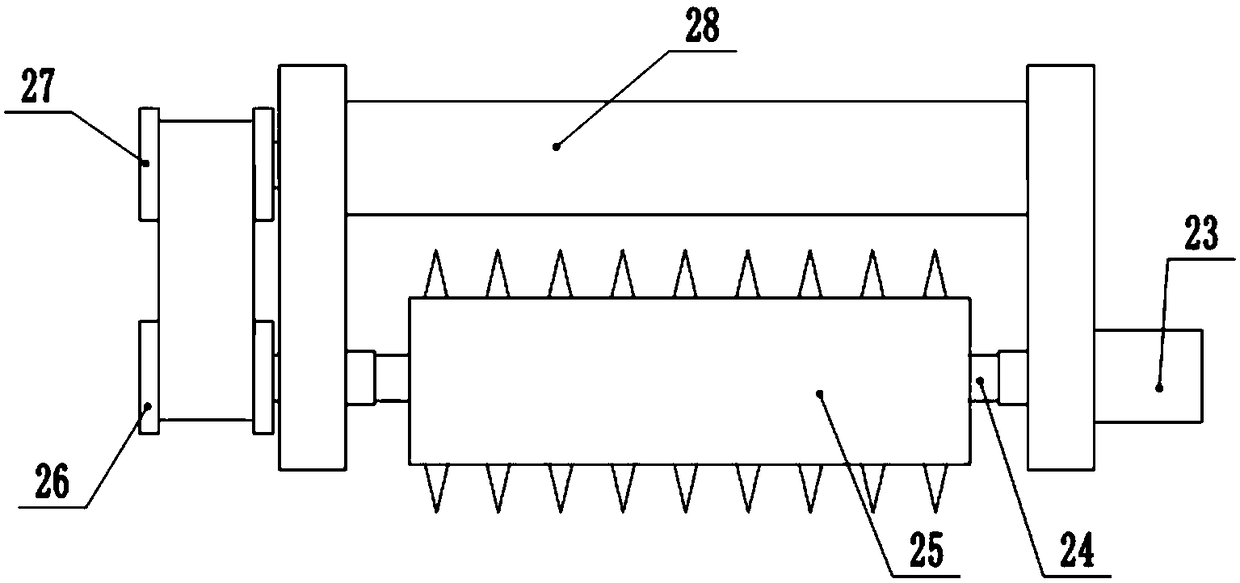

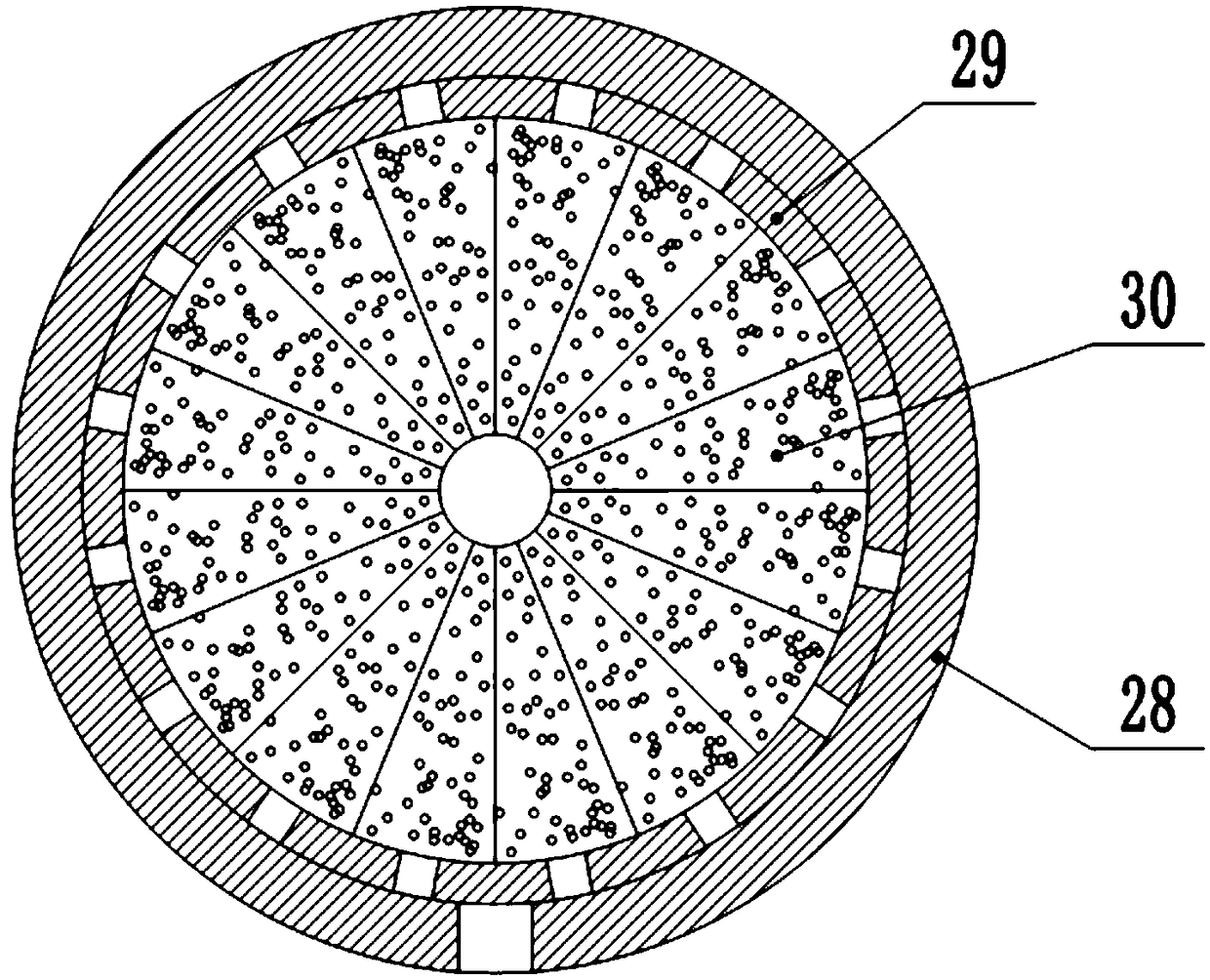

[0022] see Figure 1-3 , a vegetable seeder, comprising a main support 1, an auxiliary support 13, a lifting frame 20, a turning roller 25, a fixed cylinder 28 and a rotating cylinder 29, and the left and right parts of the lower side of the main support 1 are fixed by self-tapping screws The first driving motor 2 is installed, the output shaft of the first driving motor 2 is forward and the driving wheel 3 is installed with an interference fit on the output shaft of the first driving motor 2, and the lower side of the main bracket 1 is also fixedly installed with the first A connecting rod 4, the other end of the first connecting rod 4 is hinged with a second connecting rod 5, and the other end of the second connecting rod 5 is rotatably mounted with a driven wheel 6, and a roller 7 is concentrically installed on the driven wheel 6, and the driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com