Axial injection end combustion solid-liquid rocket engine structure

A solid-liquid rocket and engine technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low filling fraction, long and thin, and limited application range, so as to improve the filling fraction, specific impulse and Performance, the effect of ensuring thermal protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

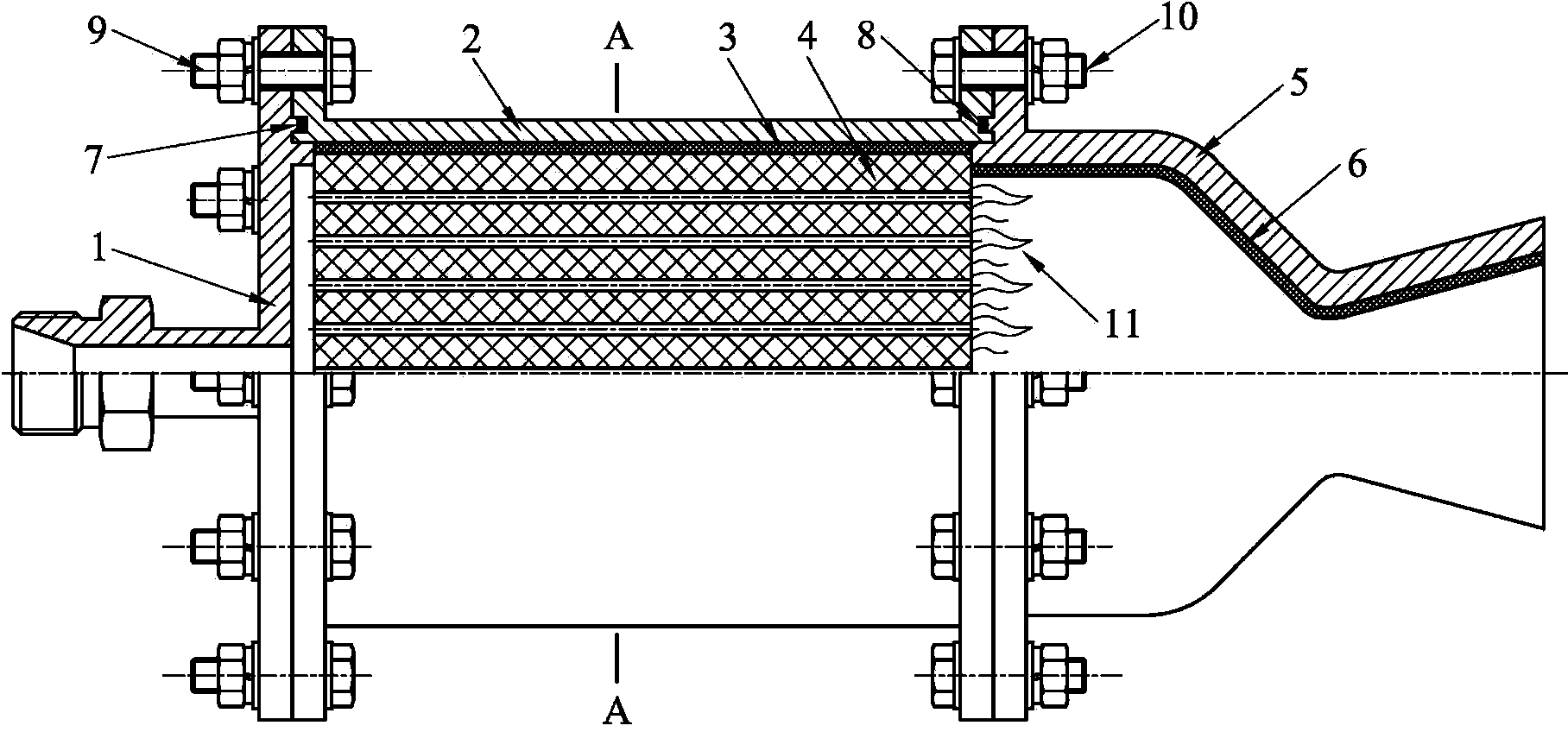

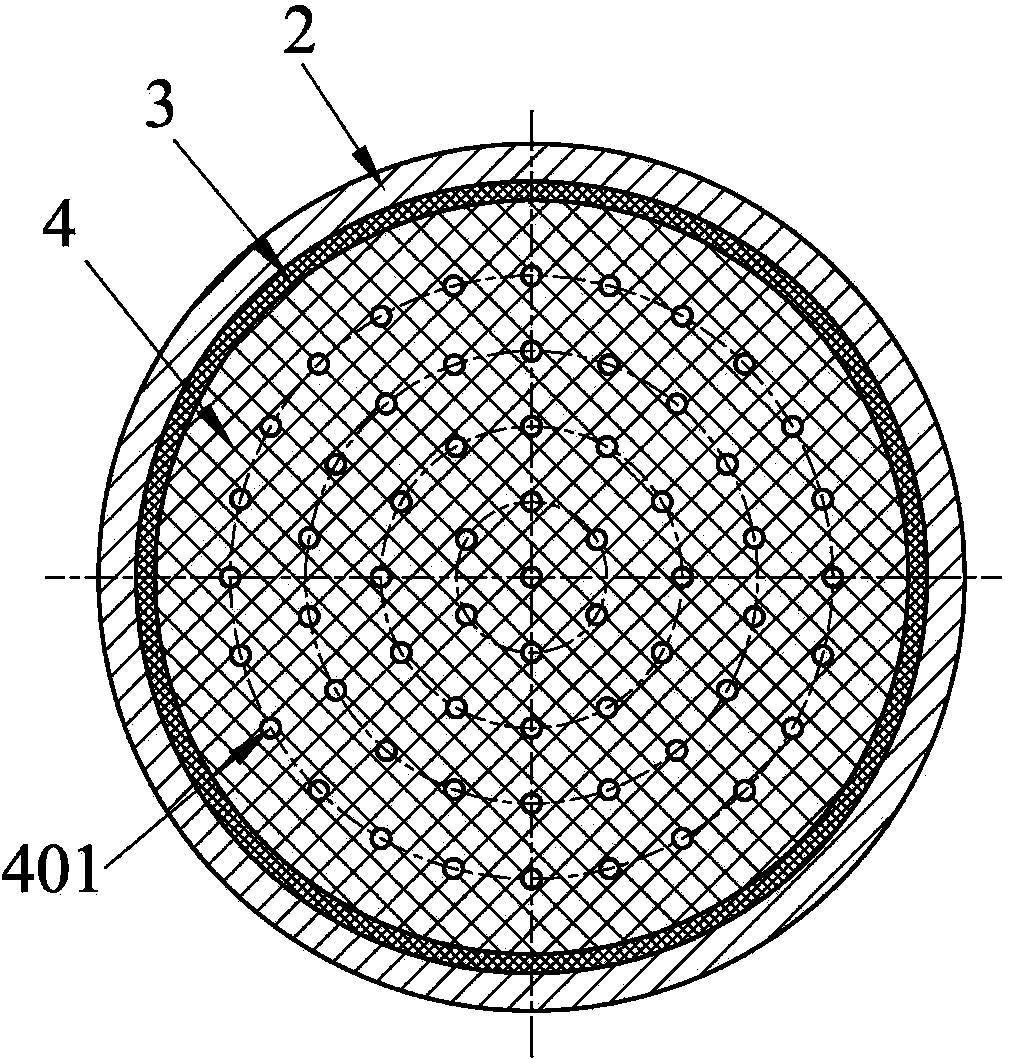

[0021] The structure of the axial injection end-combustion solid-liquid rocket engine of the present invention comprises a motor head cover 1, a charge shell 2, a charge insulation layer 3, an end-fire charge 4, a nozzle casing 5, a nozzle insulation layer 6, Sealing ring A7, bolt assembly A8, sealing ring B9, and bolt assembly B10.

[0022] The drug column housing 2 has a cylindrical structure, with connecting flanges at the front and rear ends; and the front and rear end surfaces of the drug column housing 2 have circumferential sealing grooves, and sealing rings A7 and sealing rings are arranged inside respectively. B9.

[0023] The front end of the engine head cover 1 has an air intake passage for supplying oxidant, and the oxidant can be gas oxidant such as O2 and N2O. The rear end surface of the engine head cover 1 is designed with inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com