Concrete shear wall with lead core energy-consuming device and built-in steel plate and manufacturing method

A technology of steel plate concrete and energy-dissipating devices, which is applied in the processing of walls, building materials, building components, etc., can solve the problems of weak earthquake resistance and poor energy-dissipating capacity, and facilitate factory processing, enhance energy-dissipating capacity, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

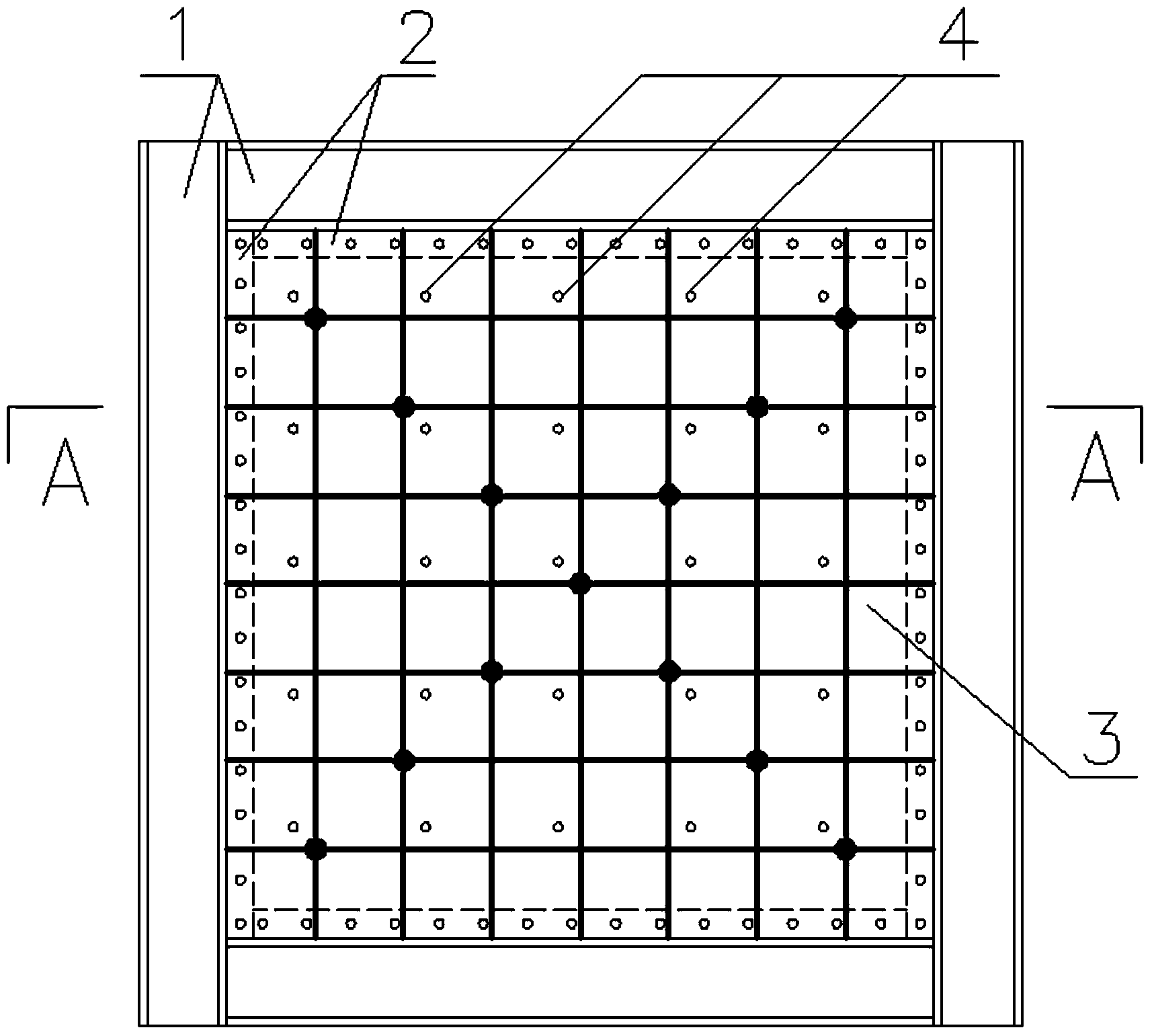

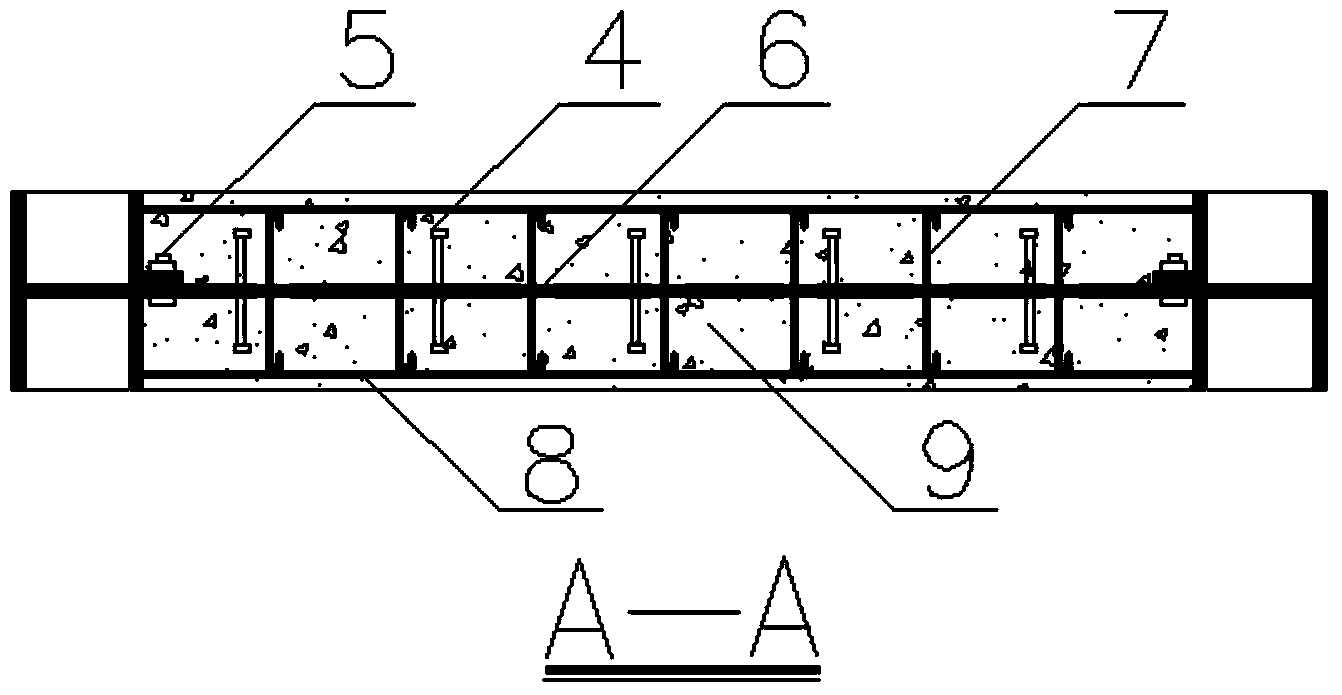

[0026] A built-in steel plate concrete shear wall with a lead core energy dissipation device, including a steel frame 1, a connecting plate 2 with bolt holes, a steel plate 3 with diagonally distributed round holes, studs 4, and high-strength bolts 5 , round lead block 6 with round holes, tie bars 7, steel mesh sheets 8, high-strength concrete 9; connecting plate 2 with bolt holes is welded on profiled steel frame 1; stud 4 is welded on Both sides of the steel plate 3 with round holes in the corner distribution; use high-strength bolts 5 to fasten and connect with the connecting plate 2 with bolt holes; fill the round holes with the round holes in the steel plate 3 with round holes Circular lead weight 6, tie steel bar 7 passes through the round hole of lead weight 6 and binds with reinforcement mesh 8 on both sides of steel plate 3 with diagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com