Formation method of high-performance selective absorption treatment membrane

A selective, membrane-treating technology, applied in solar thermal power generation, metal material coating process, heating devices, etc., can solve the problem of failing to achieve the heat-collecting properties of selective absorption treatment membranes, and improve the selective absorption performance, The effect of improving thermal efficiency and film density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0054] Hereinafter, the present invention will be described in further detail with reference to specific examples, but the scope of the present invention is not limited thereto.

Embodiment 1~12、 comparative example 1~13)

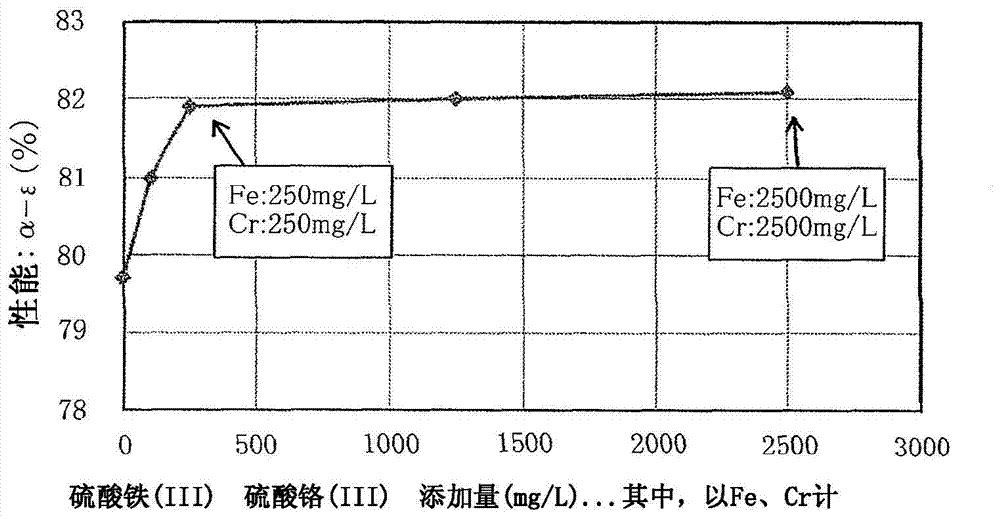

[0056] In the following treatment solution, the stainless steel plate (SUS444) was reacted at the immersion time and sulfate concentration shown in Tables 1 to 3 while the stainless steel plate (SUS444) was in a treatment bath at 116°C. It should be noted that Fe 2 (SO 4 ) 3 and Cr 2 (SO 4 ) 3 Add in equal amounts. The raw materials of the treatment liquid used are reagents from Kanto Chemical Co., Ltd., Japan.

[0057] [Treatment liquid components]

[0058]

[0059] The evaluation of selective absorption characteristics was carried out as described below.

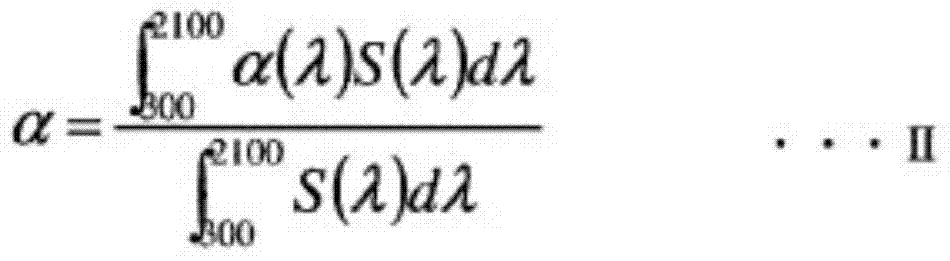

[0060] The absorption rate α is calculated by measuring the reflectance R in the UV, visible light, and near-infrared regions (300-2100 nm) using JASCO Corporation V-570, and using the formulas I and II of the following formula 1.

[0061] The emissivity ε was calculated by measuring the reflectance R in the infrared region (2500-25000 nm) using the FT / IR-400 manufactured by JASCO Corporation, and using the form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com